Method for preparing graded porous carbon with hollow mesoporous silicon spheres as templates

A hollow mesoporous and hierarchical porous technology, applied in nanotechnology and other directions, can solve the problems of complex preparation process, and achieve the effect of simple preparation process, large specific surface area, and suitable for large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

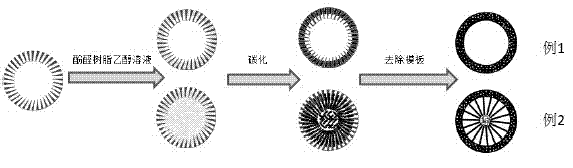

Embodiment 1

[0029] Stir 28ml of ethanol, 53ml of deionized water and 0.16g of cetyltrimethylammonium bromide at room temperature, then add 1ml of tetraethyl orthosilicate and 1ml of ammonia water, and continue stirring for 8 hours to obtain hollow mesoporous silicon spheres. Then add 0.5g of 20wt% ethanol solution of phenolic resin, continue to stir for 16 hours, pour it into a petri dish and place it in an oven to cure for 24 hours at 100°C, and put the resulting yellow powder in a tube furnace under nitrogen. The black powder was obtained after calcination at 800°C for 4 hours under the protection of 800°C. Finally, the hollow mesoporous silicon sphere template was removed with 5% hydrofluoric acid to obtain a uniformly dispersed hierarchical porous carbon with a hollow core and a mesoporous wall.

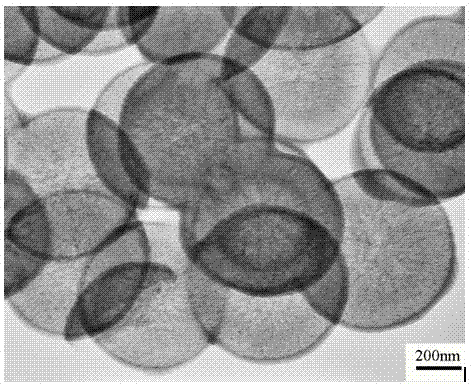

Embodiment 2

[0031] Stir 28ml of ethanol, 53ml of deionized water and 0.16g of hexadecyltrimethylammonium bromide at room temperature, then add 1ml of tetraethyl orthosilicate and 1ml of ammonia water, and continue stirring for 8 hours (6~8h is acceptable) Finally, hollow mesoporous silica spheres are obtained. Then add 2g of 20wt% ethanol solution of phenolic resin, continue to stir for 16 hours, pour it into a petri dish, put it in an oven and cure it for 24 hours at 100°C (80-160°C is acceptable), and put the obtained yellow powder Calcined in a tube furnace at 800°C (600-950°C) for 4 hours under the protection of nitrogen to obtain a black powder, and finally removed the hollow medium with 5% (5-20% concentration) hydrofluoric acid. Hierarchical porous carbon with hollow cores and mesoporous walls is obtained after being templated by porous silicon spheres.

example 3

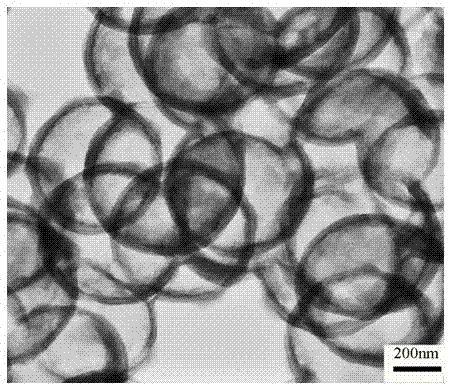

[0032] Example 3 Characterization of porous carbon

[0033] The hierarchical porous carbon prepared in the above example 1 was characterized by specific surface area and pore size distribution with a transmission electron microscope (JEOL H-800) and a nitrogen adsorption-desorption analyzer (Micromeritics ASAP 2020) respectively, the results are as follows Figure 4 and shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com