Preparation method of nano-imprint template in vector type AFM (atomic force microscopy) nano processing system

A nano-fabrication and nano-imprinting technology is applied in the manufacture of microstructure devices, metal material coating processes, and processes for producing decorative surface effects. It can solve problems such as restricting the development of nano-imprinting technology and achieve good control The effect of stability and stability, high processing accuracy, and loose processing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

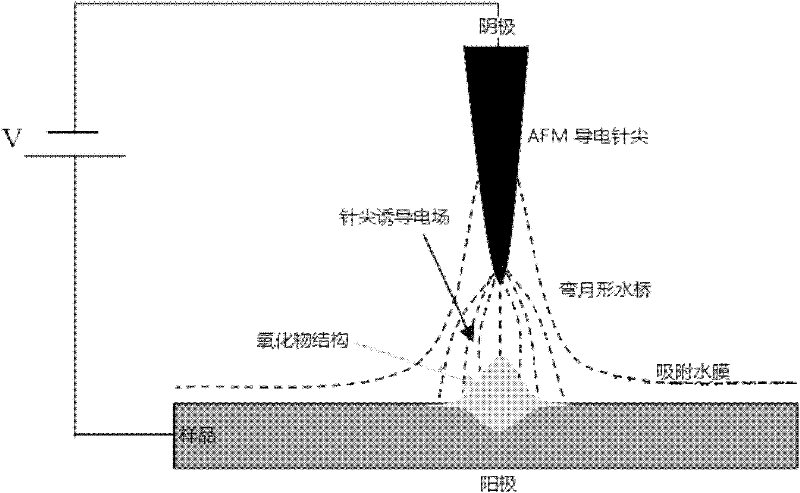

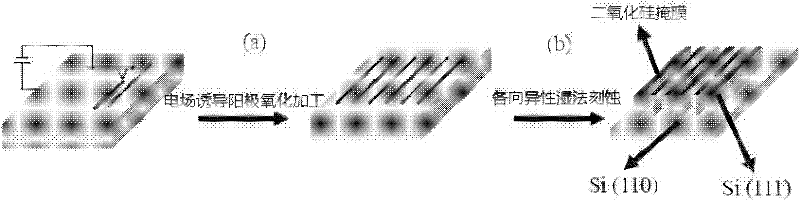

[0040] This embodiment mainly includes the following steps:

[0041] The first step, sample preparation. The improved RCA cleaning scheme was used to prepare the surface hydrogen-passivated silicon wafer samples to prevent the samples from being easily oxidized when exposed to the atmosphere, and to make the surface roughness of the cleaned samples around 0.1nm;

[0042] The second step is to fix the prepared silicon wafer sample on the object carrier with copper conductive glue or conductive silver paste, put it on the AFM stage, select the appropriate conductive probe according to the conductivity of the sample, and install the probe frame , turn on the switch of the vector AFM nano-processing system, and wait for the temperature and humidity and the AFM circuit processing system to reach a stable state. A digital multimeter for measuring physical quantities such as weak currents, warming up the instrument and waiting for it to stabilize;

[0043] The third step is to carr...

Embodiment 2

[0082] Contact mode processing under the application of a constant electric signal, at this time, the system's own DC signal can also be used for field-induced processing.

[0083] The first step, sample preparation refers to Example 1.

[0084] The second step is to fix the prepared silicon wafer sample on the object carrier with copper conductive glue or conductive silver paste, put it on the AFM stage, select the appropriate conductive probe according to the conductivity of the sample, and install the probe frame , turn on the switch of the vector AFM nano-processing system, and wait for the temperature and humidity and the AFM circuit processing system to reach a stable state. A digital multimeter for measuring physical quantities such as weak currents, warming up the instrument and waiting for it to stabilize;

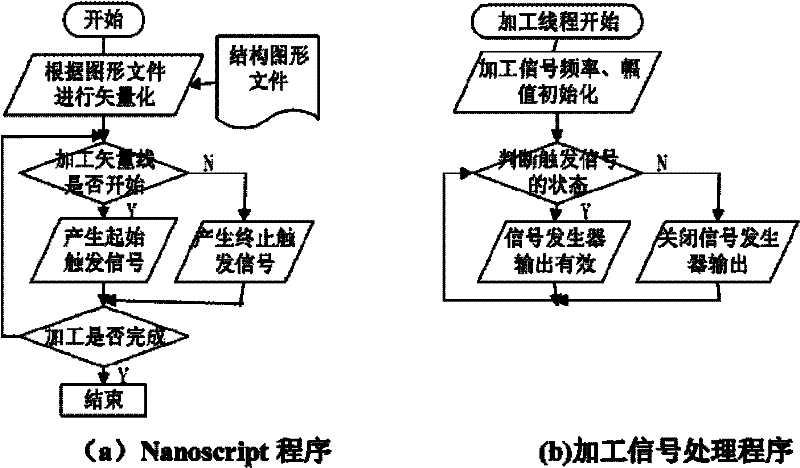

[0085] The third step is to program the required nanostructure, and the program controls the movement of the probe tip.

[0086] According to the geometric shap...

Embodiment 3

[0104] Percussion-mode processing under application of a steady-state electrical signal.

[0105] The first step and the second step of the process are the same as in Example 2, and the third step of the process is the same as in Example 1.

[0106] The fourth step, AFM enters the imaging mode scanning state, set the appropriate scanning range (1 μm ~ 50 μm), scanning rate (0.1 μm / s ~ 1 μm / s), integral gain (for AFM contact mode: ~ 2.00, for knocking mode : ~0.30), proportional gain (for AFM contact mode: ~3.00, for tapping mode: ~0.50) and probe oscillation amplitude and other parameters, and then start scanning the sample surface, so that the stability and repeatability of the scanning image can be achieved. most;

[0107] Step 5. After the scanning process is stable and a stable and repeatable scanning image is obtained, enter the script program mode, call out the Nanoscript interface and then call the previously edited processing macro file to control the waveform and dut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface average roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com