Ink taking dimethyl carbonate as solvent and preparation method for ink

A technology of dimethyl carbonate and ink, applied in the field of ink, can solve the problems of large solvent residue and excessive benzene content, and achieve the effects of good gloss, low solvent residue, and safe production and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

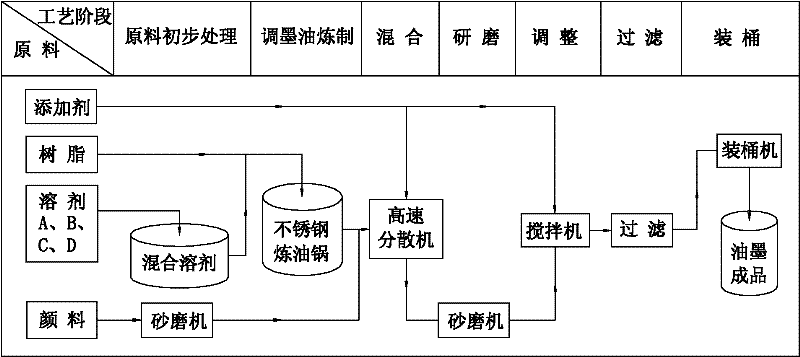

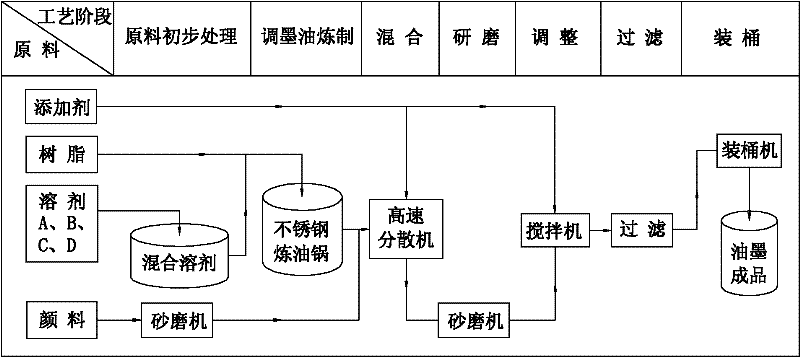

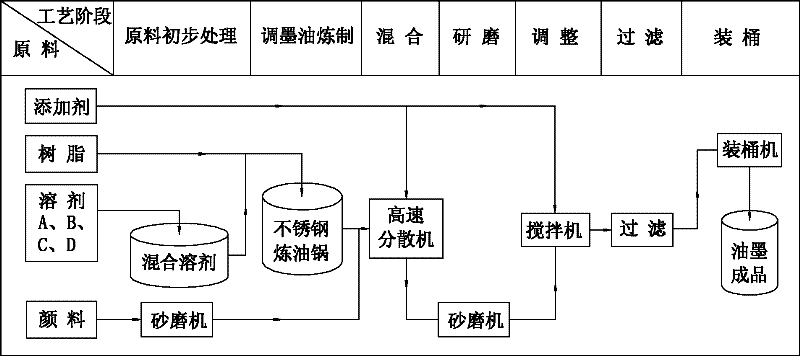

Method used

Image

Examples

example 1

[0020] An ink using dimethyl carbonate as a solvent, the raw materials and proportion of the ink are as follows: dimethyl carbonate is added in an amount of 30% of the weight of the ink, methylcyclohexane is 15%, ethyl acetate is 12%, iso Propanol 5%, resin 15%, 99R imported carbon black 20%, butanone 1.5%, dispersant 1.5%.

[0021] The above-mentioned preparation method of the gravure printing ink that is used for PET base material is as follows:

[0022] (1) Raw material preliminary treatment process: Mix 30% dimethyl carbonate, 15% methylcyclohexane, 12% ethyl acetate and 5% isopropanol to make a mixed solvent;

[0023] (2) Refining process of varnish: use the above mixed solvent to dissolve 15% resin of ink weight to form a resin solution with a certain concentration;

[0024] (3) Mixing process: mix the above resin solution with 20% of the ink weight of organic pigment 99R imported carbon black, stir and disperse to prepare a semi-finished color paste;

[0025] (4) Gri...

example 2

[0029] As described in Example 1, the difference is that the ink raw materials and proportions are: the addition of dimethyl carbonate is 30% of the ink weight, methylcyclohexane is 6%, ethyl acetate is 10%, isopropanol 5% for resin, 16% for resin, 30% for titanium dioxide, 1.5% for methyl ethyl ketone, and 1.5% for dispersant, and the finished white ink is obtained.

example 3

[0031] As described in Example 1, the difference is that the ink raw materials and proportioning are: the addition of dimethyl carbonate is 22% of the ink weight, methylcyclohexane is 14%, ethyl acetate is 10%, isopropanol 6% for resin, 15% for resin, 30% for pigment red, 1% for methyl ethyl ketone, and 1% for dispersant. That is, the finished product of red ink is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com