Construction method of genetic engineering strain for producing shikimic acid

A technology of genetically engineered strains and construction methods, which is applied in the field of construction of genetically engineered strains for shikimic acid production, can solve problems such as cumbersome operations, and achieve the effects of accelerating synthesis reactions, reducing catabolism, and simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

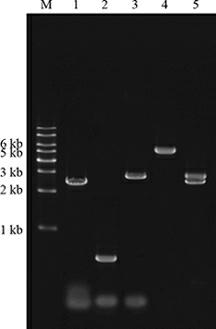

[0051] A method for constructing a genetically engineered bacterial strain for shikimic acid production, comprising the following steps:

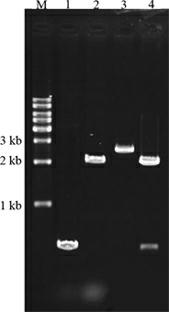

[0052] 1. Construction aroA The knockout Escherichia coli strain W3110 ( ?aroA );

[0053] The principle of Red recombination technology is to introduce two DNA fragments containing the homologous sequence of the target gene into the host bacterium, and under the action of recombinase, the target gene fragment is replaced by other fragments to complete the knockout of the target gene.

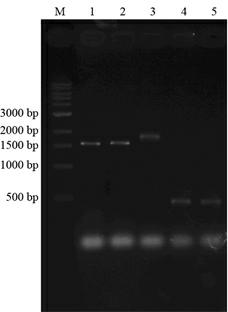

[0054] )a、 Obtained by PCR amplification aroA Homologous replacement sequence DaroA;

[0055] Using plasmid pKD4 (provided by Shanghai Institutes for Biological Sciences, Chinese Academy of Sciences) as a template, using primers aroAF (see sequence 1 in the sequence listing) and aroAR (see sequence 2 in the sequence listing), PCR amplifies the can R Gene. The 5' end of the homologous recombination primer is the homologous sequence on both sid...

Embodiment 2

[0162] Example 2 Production of shikimic acid by fermentation

[0163] Will construct successful target engineering strains E. coli W3110 (? aroA ) pAR63 was activated on the slant, inoculated in LB medium, cultured to OD at 37°C, 220r / min 600 At ≈2, inoculate in a 5L fermenter, the fermenter is filled with 2.4L, the fermentation medium is: glucose 15g, yeast extract 1g, K 2 HPO 4 8g, citric acid monohydrate 2.5g, L-Phe 0.7g, L-Tyr 0.7g, L-Trp 0.7g, MgSO 4 0.24g, H 3 BO 3 0.0247g, ZnSO 4 ·7H 2 O 0.0029g, CuSO 4 ·5H 2 O 0.0025g, MnCl 4H 2O 0.0158g, p-hydroxybenzoic acid 0.010g, p-aminobenzoic acid 0.010g, 2,3-dihydroxybenzoic acid 0.010g. The fermentation temperature is 37°C, the initial stirring speed is 50r / min, and the initial ventilation rate is 1:0.1. At first, control the dissolved oxygen at 30% by controlling the speed. When the speed reaches the highest 800r / min, control the dissolved oxygen at 20% by adjusting the ventilation rate. When the ventilatio...

Embodiment 3

[0165] Example 3 Production of shikimic acid by fermentation

[0166] Will construct successful target engineering strains E. coli W3110 (? aroA ) pAR63 was activated on the slant, inoculated in LB medium, cultured to OD at 37°C, 220r / min 600 At ≈2, inoculate in a 5L fermenter, the fermenter is filled with 2.4L, the fermentation medium is glucose 15g, yeast extract 1g, K 2 HPO 4 8g, citric acid monohydrate 2.5g, L-Phe 0.7g, L-Tyr 0.7g, L-Trp 0.7g, MgSO 4 0.24g, H 3 BO 3 0.0247g, ZnSO 4 ·7H 2 O 0.0029g, CuSO 4 ·5H 2 O 0.0025g, MnCl 4H 2 O 0.0158g, p-hydroxybenzoic acid 0.010g, p-aminobenzoic acid 0.010g, 2,3-dihydroxybenzoic acid 0.010g. The fermentation temperature is 37°C, the initial stirring speed is 50r / min, and the initial ventilation rate is 1:0.1. At first, control the dissolved oxygen at 30% by controlling the speed. When the speed reaches the highest 800r / min, control the dissolved oxygen at 20% by adjusting the ventilation rate. When the ventilatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com