Copper-cobalt-silicon catalyst used in preparation of lower alcohol from synthetic gas and preparation method thereof

A low-carbon alcohol and synthesis gas technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, organic compounds, etc., can solve the problems of low water content in products, slow industrialization process, loss of cobalt carbonyl, etc., and achieve mild reaction conditions , low carbon alcohol activity and the effect of selectivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

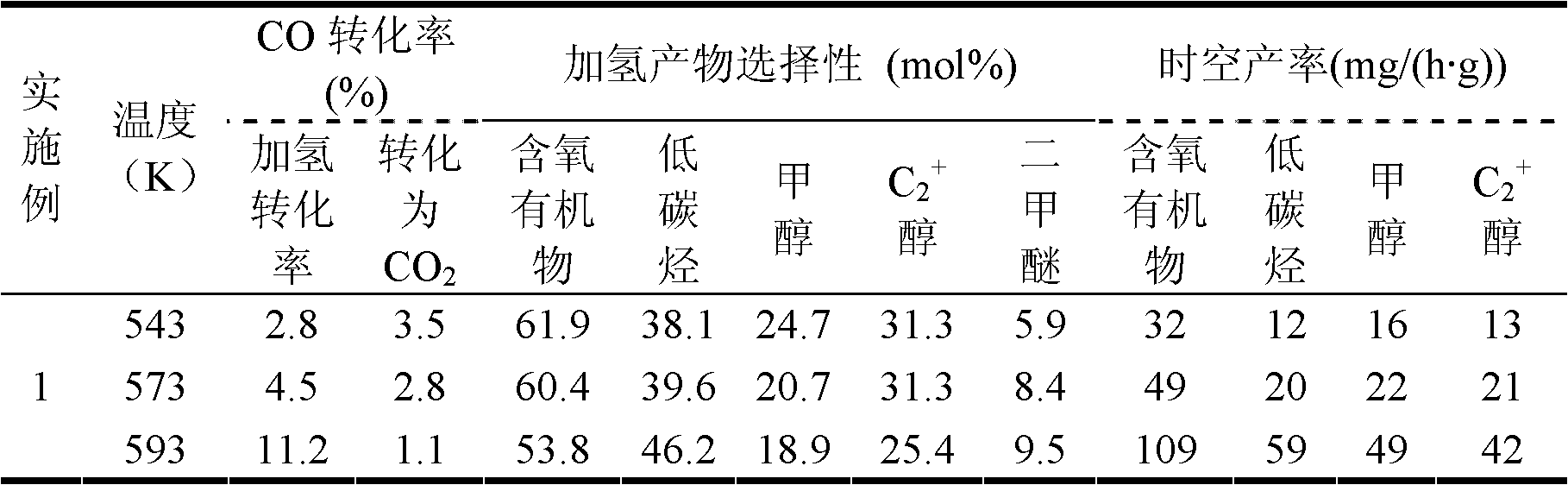

Embodiment 1

[0017] 1) Weigh 2.0723g Cu (NO 3 ) 2 ·3H 2 O and 0.3821g Co(NO 3 ) 2 ·6H 2 O, add 200mL of anhydrous ethanol solution dissolved with 5.0525g of citric acid monohydrate, sonicate for 5min to fully dissolve to a transparent solution, stir at 60°C for 3h, and the pH of the solution is 2.

[0018] 2) Add 40mL deionized water, then add 7.8mL tetraethyl orthosilicate dropwise while stirring, continue to stir for 1h, then evaporate to dryness in a water bath at 80°C until gelatinous, dry in an oven at 120°C for 1h, then place at 350°C ℃ under air atmosphere for 4 h to obtain the catalyst precursor.

[0019] 3) Tablet sieving 40 ~ 60 mesh catalyst precursor in 5% H at normal pressure 2 / Ar (volume percent) gas flow (flow rate: 30mL / min) 2 ℃ / min temperature program to 350 ℃ reduction for 12 hours to obtain synthesis gas to prepare low-carbon alcohol copper cobalt silicon catalyst Cu 3 co 1 -SiO 2 .

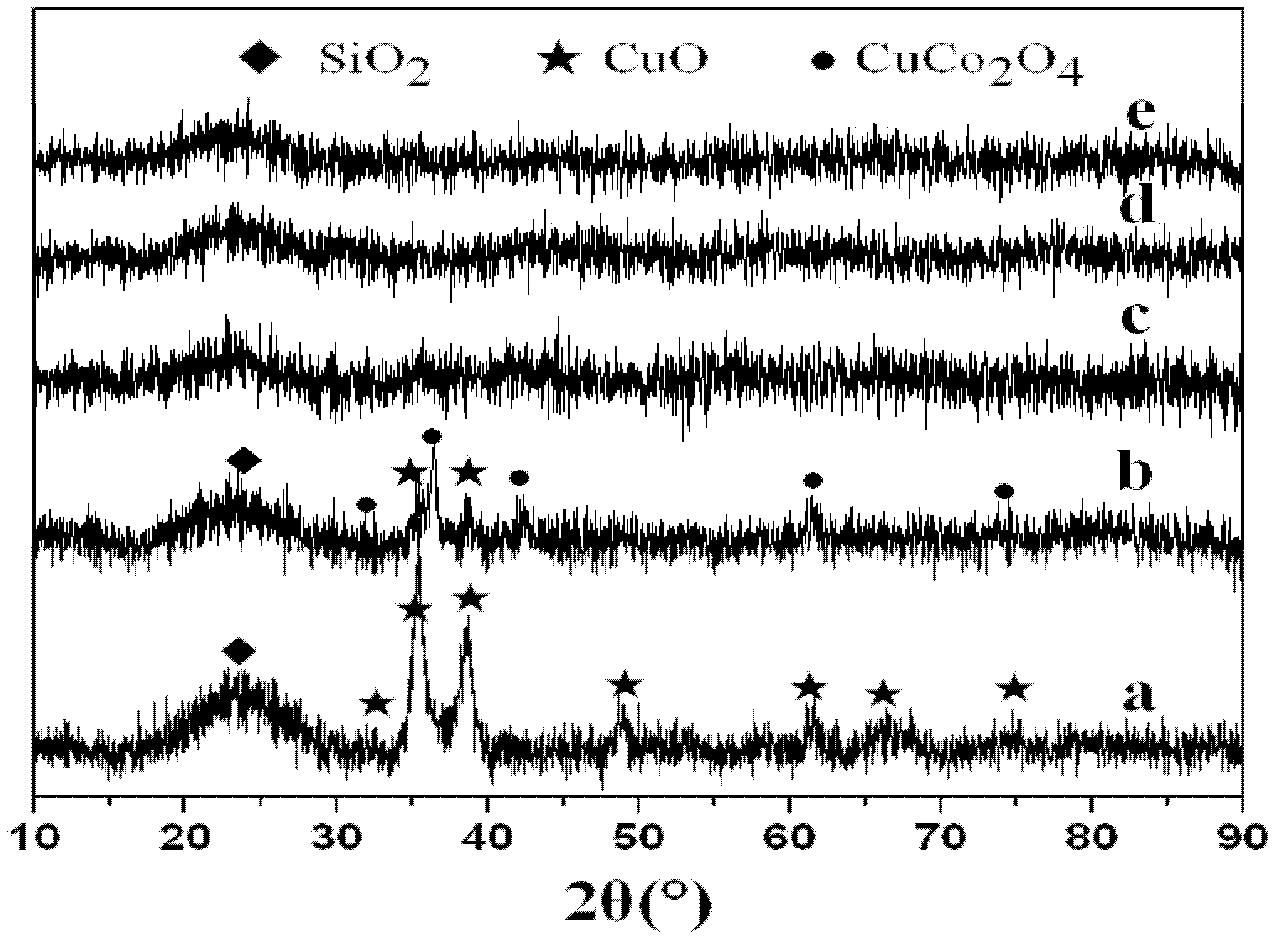

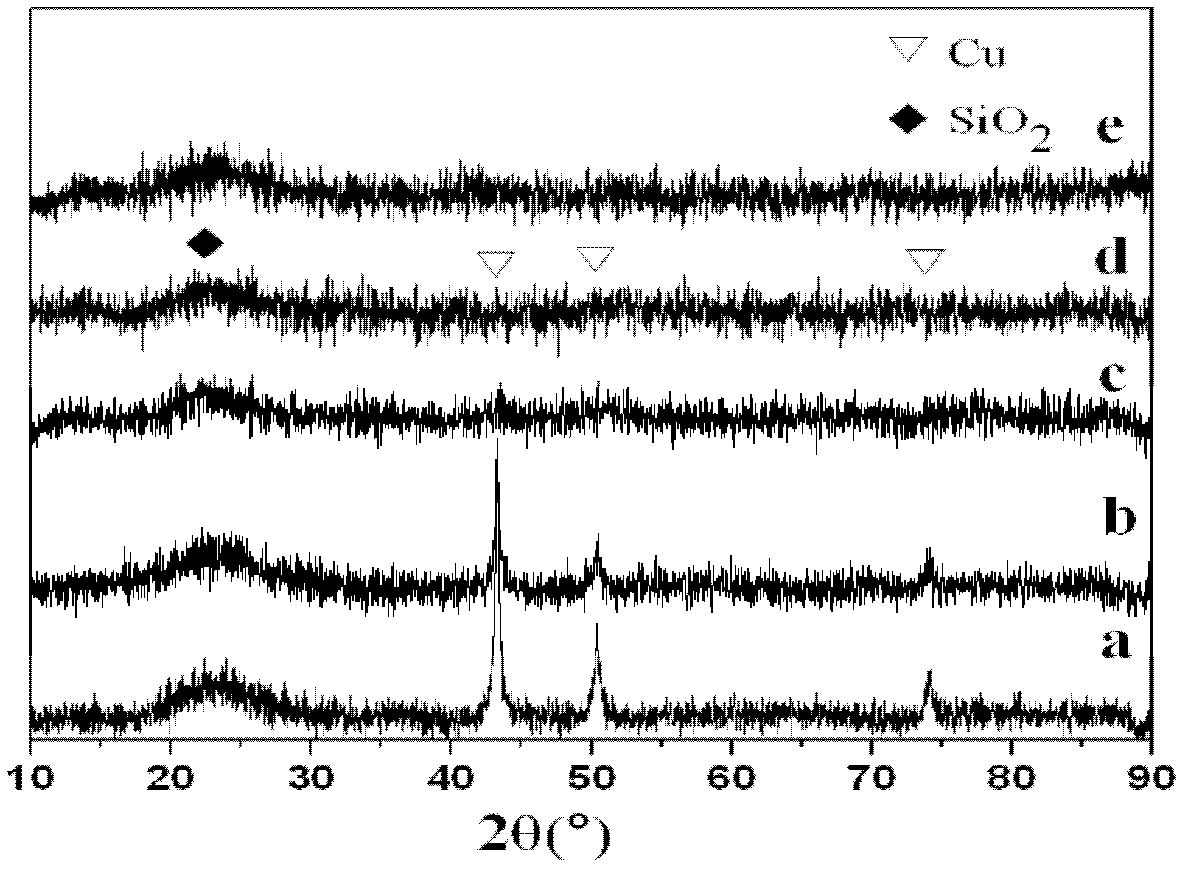

[0020] Use Panalytical Xpert PRO powder X-ray diffractometer (graphite mon...

Embodiment 2

[0026] 1) Weigh 1.4077g Cu (NO 3 ) 2 ·3H 2 O and 1.6956g Co(NO 3 ) 2 ·6H 2 O, add 200 mL of anhydrous ethanol solution dissolved with 4.8940 g of citric acid monohydrate, sonicate for 5 min to fully dissolve to a transparent solution, stir at 60°C for 3 h, and the pH of the solution is 3 at this time.

[0027] 2) Same as step 2 in Example 1.

[0028] 3) same as step 3 in embodiment 1, the copper-cobalt-silicon catalyst Cu of low carbon alcohol is obtained 1 co 1 -SiO 2 .

[0029] The activity evaluation of the catalyst is the same as in Example 1, and the results are shown in Table 2. The surface physical properties of the catalysts are listed in Table 6.

[0030] Table 2. Example 2 activity evaluation results

[0031]

Embodiment 3

[0033] 1) Weigh 0.7173g Cu (NO 3 ) 2 ·3H 2 O and 2.5921g Co(NO 3 ) 2 ·6H 2 O, add 200mL of anhydrous ethanol solution in which 5.2463g of citric acid monohydrate is dissolved, ultrasonicate for 5min to fully dissolve into a transparent solution, stir at 60°C for 3h, and the pH of the solution is 1 at this time.

[0034] 2) Same as step 2 in Example 1.

[0035] 3) same as step 3 in embodiment 1, the copper-cobalt-silicon catalyst Cu of low carbon alcohol is obtained 1 co 3 -SiO 2 .

[0036] The activity evaluation of the catalyst is the same as in Example 1, and the results are shown in Table 3. The surface physical properties of the catalysts are listed in Table 6.

[0037] Table 3. Example 3 activity evaluation results

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com