Preparation method of graphene

A graphene and solvent technology, applied in the field of synthesis of inorganic chemical materials, can solve the problems of low cost, complex process conditions, and low yield, and achieve good reproducibility, mild reaction conditions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

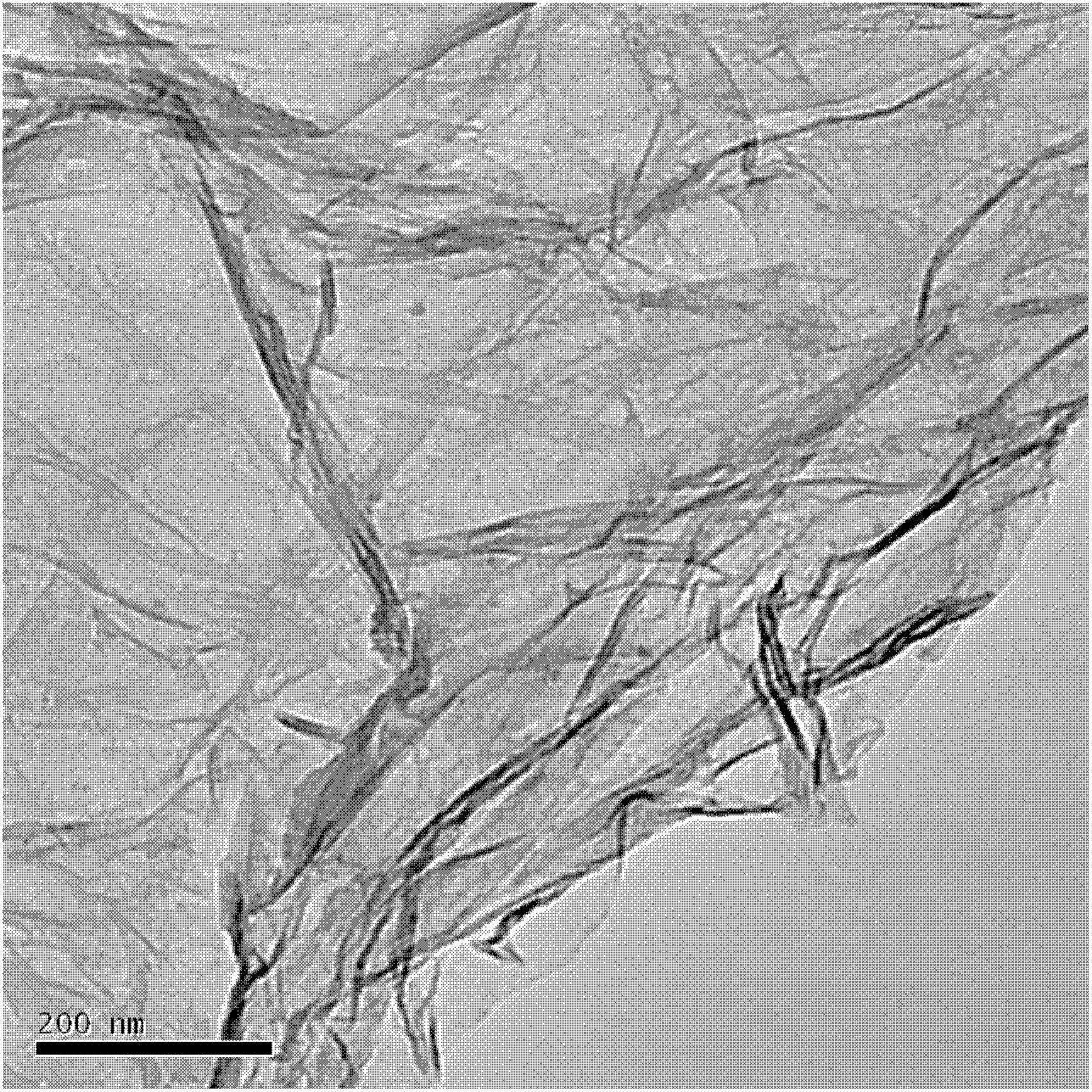

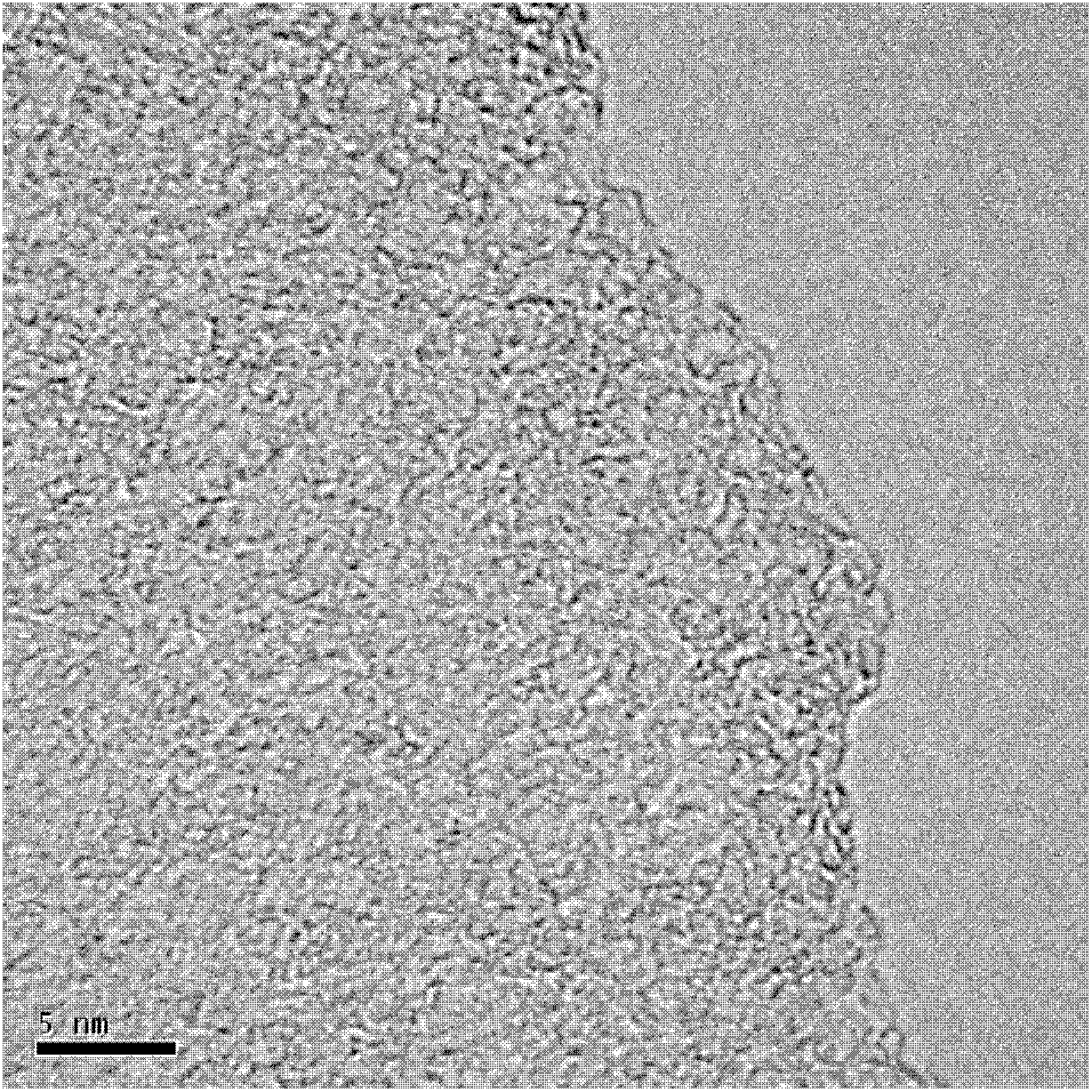

[0043] Put 20mL of diethylene glycol dimethyl ether in a 50mL round bottom flask, then add 0.04g of hexabromobenzene (equivalent to 2mg / mL) and 0.01g of CuBr (equivalent to 0.5mg / mL), stir, and After 30 minutes of pure Ar gas, the oil bath was heated at 140° C., and the reaction was carried out for 14 hours. The Ar gas atmosphere of the reaction system was maintained until the reaction system was naturally cooled to room temperature to obtain graphene. See figure 1 and figure 2 .

Embodiment 2

[0045] Put 20mL of toluene in a 50mL round bottom flask, then add 0.002g of hexabromobenzene (equivalent to 0.1mg / mL), 0.001g of CuCl (equivalent to 0.05mg / mL), stir, and heat in an oil bath under air conditions, the temperature is 100°C, reflux for 4 hours, and then naturally cool to room temperature to obtain graphene.

Embodiment 3

[0047] Put 20mL of diethylene glycol dimethyl ether in a 50mL round bottom flask, then add 1g of hexabromobenzene (equivalent to 50mg / mL), and 10g of Cu powder (equivalent to 500mg / mL) in a 50mL round bottom flask, stir , after passing Ar gas for 30 min, the oil bath was heated to 160° C., and the reaction time was 6 hours. The Ar gas atmosphere of the reaction system was kept until the reaction system was naturally cooled to room temperature to obtain graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com