Method for preparing cobalt oxide nanosheet and graphene composite lithium battery cathode material through single-mode microwave

A graphene composite, negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of large particle size, low purity, poor activity of ultrafine powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

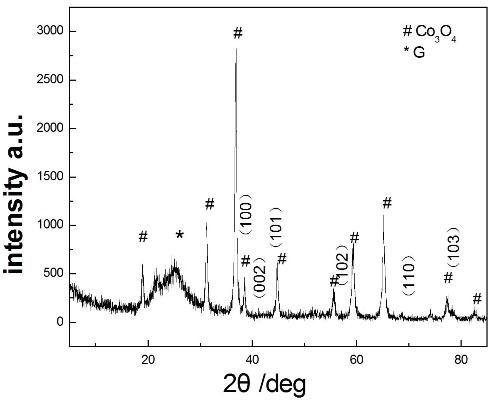

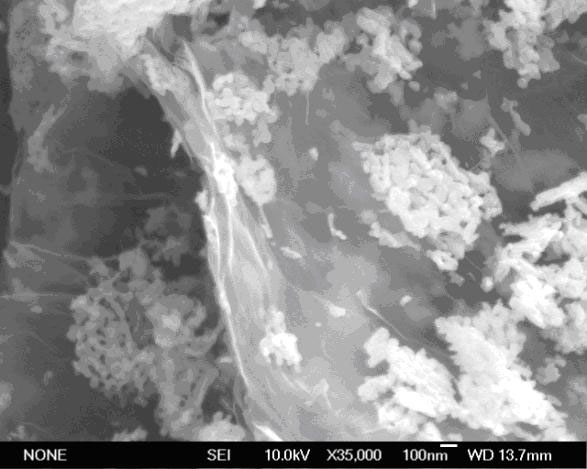

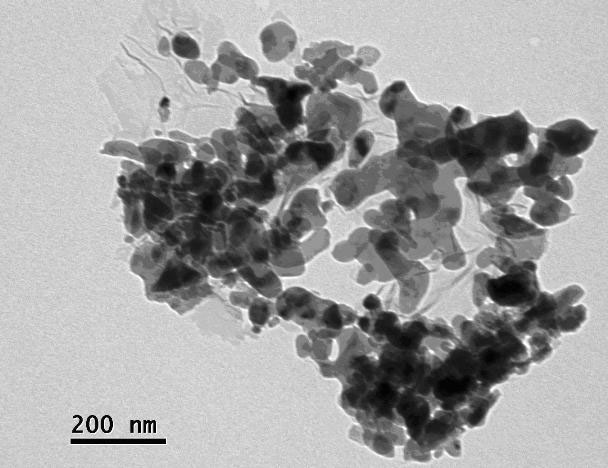

Image

Examples

Embodiment 1

[0024] Take 2 g of natural graphite powder and add it to the flask, place the flask in ice water, keep the temperature in the ice water bath at about 0 ℃, add 80 ml of HNO 3 (65%), then magnetically stirred for 10 min, and then added 120 ml H 2 SO 4 (98%), stirred for 1 h, the temperature was about 20 ℃, slowly added 10 g KMnO 4 , to avoid a sharp rise in temperature, keep the temperature at 35 ℃, add KMnO 4 Finally, magnetic stirring was carried out for 2 h, and then 400 ml of ultrapure water was added to obtain a black colloidal substance, and then 10 ml of 30% H 2 o 2 , the solution is brownish yellow, add 30 ml of 10% HCl to wash, centrifuge at a speed of about 15000-18000 rpm, wash 3 times with ultrapure water until the sample is neutral, and finally dry to obtain graphene oxide thing;

[0025] Will Co 3 o 4 : The mass ratio of G (graphene) is set to 1:1, while Co(NO 3 ) 2 ·6H 2 O:HMT=1:2 (molar ratio), take 0.189 g Co(NO3 ) 2 ·6H 2 O was dissolved in ...

Embodiment 2

[0029] Take 2 g of natural graphite powder and add it to a 1000 mL flask, place the flask in ice water, keep the temperature in the ice water bath at about 0 °C, add 80 ml of HNO 3 (65%), then magnetically stirred for 10 min, and then added 120 ml H 2 SO 4 (98%), stirred for 1 h, the temperature was around 20 ℃, slowly added 10 g KMnO 4 , to avoid a sharp rise in temperature, keep the temperature at 35 ℃, add KMnO 4 Finally, magnetic stirring was carried out for 2 h, and then 400 ml of ultrapure water was added to obtain a black colloidal substance, and then 10 ml of 30% H 2 o 2 , the solution was brownish yellow, added 30 ml of 10% HCl to wash, centrifuged, washed 3 times with ultrapure water until the sample was neutral, and finally dried to obtain graphene oxide;

[0030] Will Co 3 o 4 The mass ratio to graphene is set at 2:1, while Co(NO 3 ) 2 ·6H 2 O:HMT=1:2 (molar ratio), take 0.377 g Co(NO 3 ) 2 ·6H 2 O was dissolved in 40 ml of absolute ethanol, ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com