Recombination food-grade lactic acid bacterium capable of being used for preventing or treating human ulcerative colitis as well as preparation method and application of recombination food-grade lactic acid bacterium

A lactic acid bacteria, food-grade technology, applied in the field of genetic engineering, can solve problems such as biosafety consequences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Example 1: Acquisition of the gene encoding α-galactosidase in Lactobacillus plantarum

[0092] Plant lactobacillus (Lactobacillus plantarum (Orla-Jehsen) Holland, ATCC11095, Guangdong Provincial Microbial Culture Collection Center, number: GIM1.191) bacterial strain on GM17 plate [composition: 3.725% M17 broth (M17 Broth, purchased from Biokar Diagnostics , France), 0.5% glucose, 1.5% agar powder] for strain activation, 37 ° C anaerobic culture for 48 hours. Then, pick a single clone and transfer it to GM17 liquid medium [ingredients: 3.725% M17 broth, 0.5% glucose], anaerobic static culture at 37°C until OD 600 =0.6, the bacteria were collected by centrifugation and genomic DNA was extracted using a bacterial genome extraction kit (TaKaRa MiniBEST Bacterial Genomic DNA Extraction Kit Ver.2.0, purchased from Dalian Bao Biological Engineering Co., Ltd., Dalian, China). Using the genomic DNA as a template, add mel AF (SEQ ID NO.12) and mel AR (SEQ ID NO.13) (both synthe...

Embodiment 2

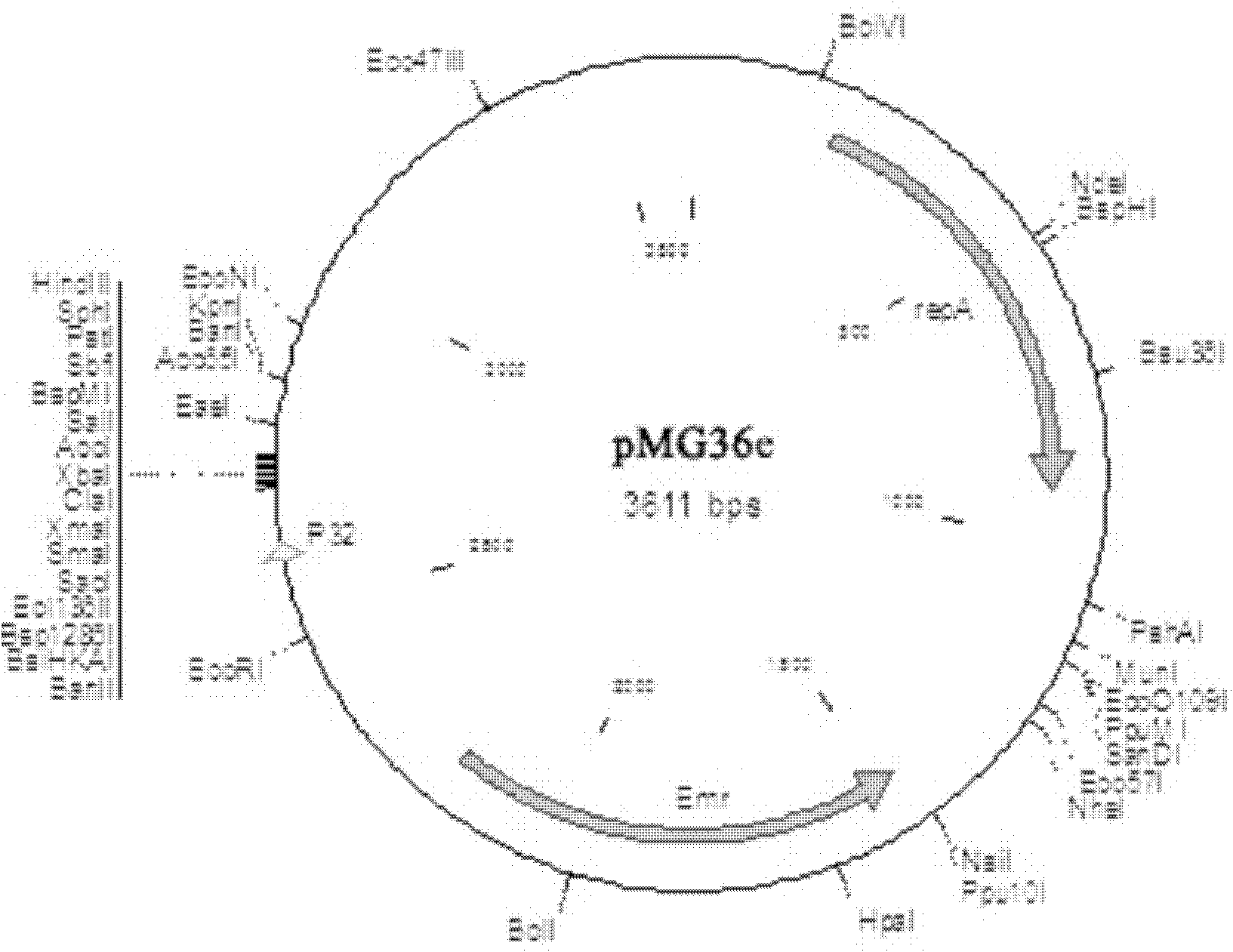

[0093] Embodiment 2: Construction of recombinant food-grade lactic acid bacteria expression vector pMG36m

[0094] The wild-type Lactococcus lactis MG1363 (purchased from NIZO Co. Ltd., Catalog: ELS09000-01, Netherlands) containing the pMG36e plasmid was cultured on an EGM17 solid culture plate containing erythromycin antibiotics (ingredients: 3.725% M17 broth, 0.5% Glucose, 1.5% agar powder, and erythromycin with a final concentration of 10 μg / ml) were streaked for culture. After 36 hours of anaerobic culture at 37°C, pick a single colony from the plate medium and inoculate it into EGM17 liquid medium containing erythromycin antibiotics (ingredients: 3.725% M17 broth, 0.5% glucose, final concentration of 10 μg / ml red Mycin), 37 ℃ anaerobic static culture to OD 600 = 0.6. The bacteria were collected by centrifugation and the plasmid pMG36e was obtained by using a plasmid extraction kit (TaKaRa MiniBEST Plasmid Purification Kit Ver.2.0, purchased from Dalian Bao Biological En...

Embodiment 3

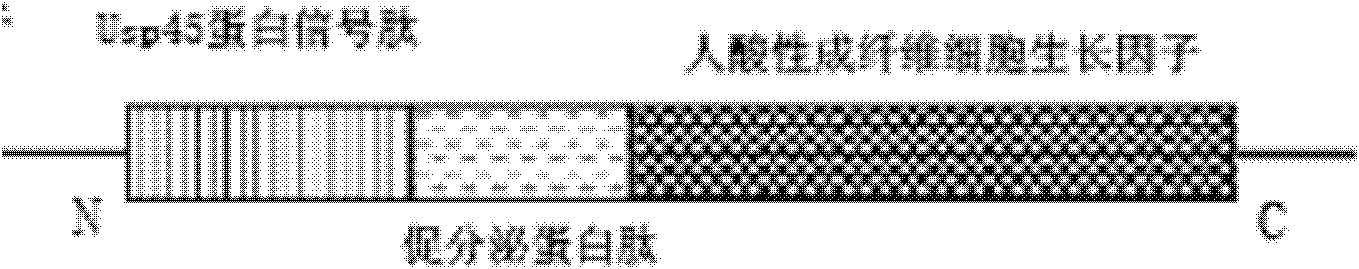

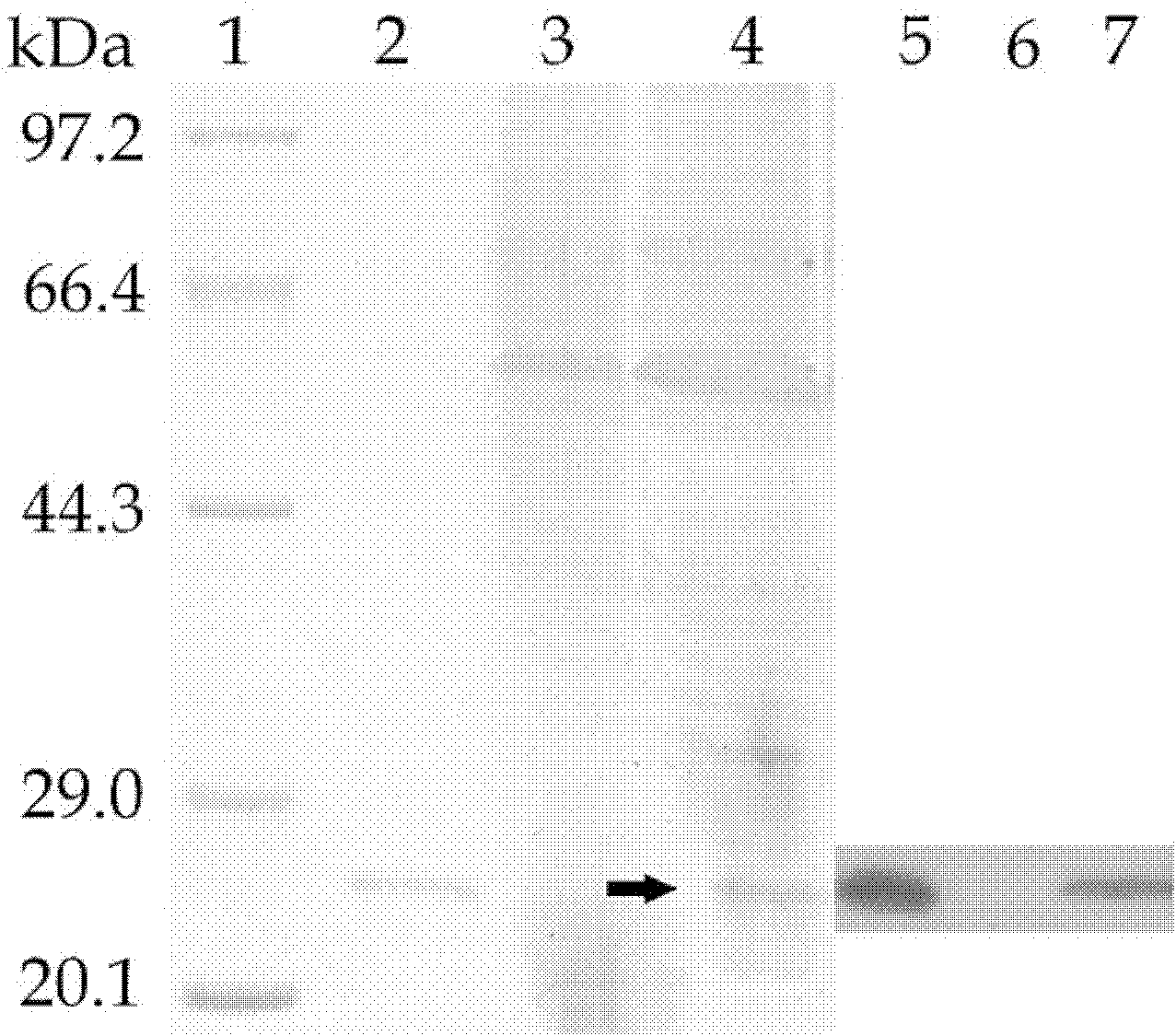

[0095] Example 3: Construction of recombinant expression plasmid pMG36m-ULHA

[0096] Send the DNA fragment (sequence: SEQ ID NO.11) encoding the fusion protein composed of Usp45 protein signal peptide, secretagogue peptide and human acidic fibroblast growth factor to Guangzhou Jetway Biotech Co., Ltd. .Ltd., Guangzhou, China) for total gene synthesis. This DNA fragment was used as a template, ULHA-F (SEQ ID NO.14) and ULHA-R (SEQ ID NO.15) were used as upstream and downstream primers, and then dNTP (each 2.5 μmol L -1 ) 10 μl, 10 μl of 10x PCR pfu buffer and 1 μl of pfu Taq DNA polymerase (5U / μl), add water to a total volume of 100 μl, and follow the standard PCR reaction conditions (94°C denaturation for 4 minutes before entering the cycle, the cycle parameter is 94°C Denaturation for 30 seconds, annealing at 58°C for 30 seconds, extension at 72°C for 60 seconds, a total of 35 cycles) to amplify the target fragment. The target DNA fragment was detected and recovered by ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com