Polydimethylsiloxane (PDMS)-based three-dimensional single cell culture chip and controllable preparation method thereof

A single-cell, three-dimensional technology, applied in tissue cell/virus culture devices, biochemical equipment and methods, bioreactors/fermenters for specific purposes, etc., can solve problems such as poor pattern shape and pattern property stability , to achieve long-term stability of pattern properties and pattern structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The chip in this example is used to culture osteoblast MC3T3-E1 to conduct research on cell contact connection. MC3T3-E1 average diameter 20μm, average height h 0 is 3 μm, the average synapse length l 0 is 20 μm.

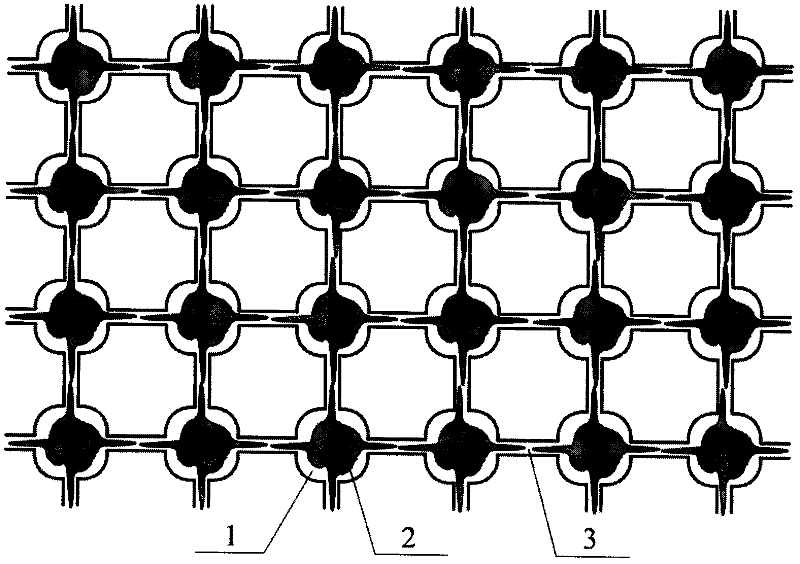

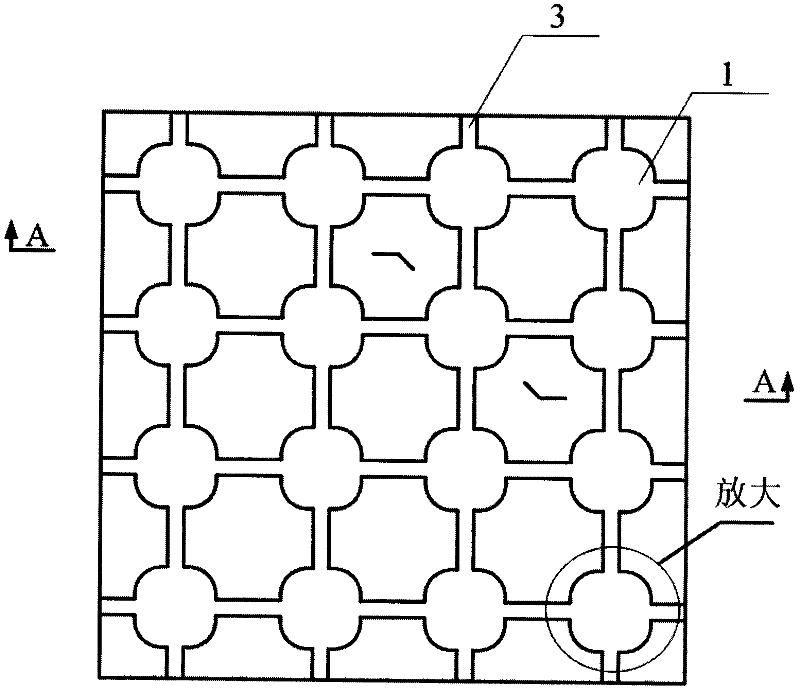

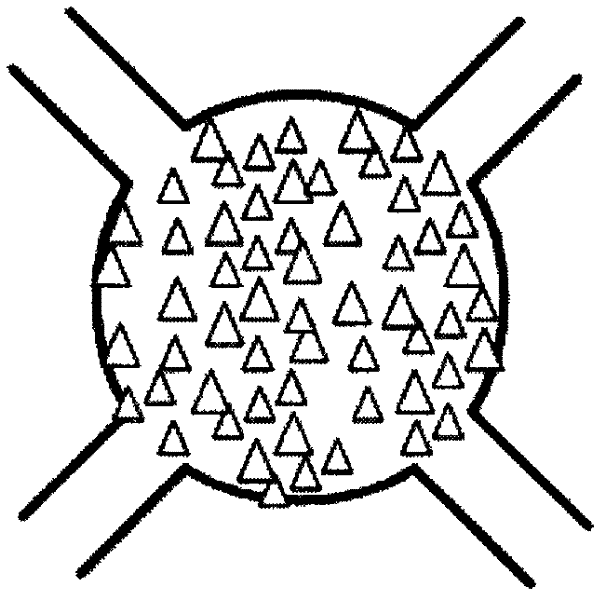

[0025] refer to Figure 1 ~ Figure 3 . The three-dimensional single-cell culture chip used for culturing MC3T3-E1 in this embodiment includes circular cavities 1 distributed in an array, and microgrooves 3 are connected between adjacent cavities 1, and the depth of microgrooves 3 is the same as that of the cavities. The height h of body 1 is 4 μm; the bottom of cavity 1 contains nanoprotrusions; the diameter of cavity 1 The distance l between two adjacent cavities 1 is 50 μm; the micro-grooves 3 are evenly distributed at 90°, and the width of the micro-grooves 3 is a=2 μm.

[0026] In this embodiment, the preparation method of the PDMS-based three-dimensional single-cell culture chip is completed by using MEMS technology and replication molding techno...

Embodiment 2

[0041] The chip in this example is used to culture human mammary epithelial cells HMEC to conduct research on cell non-contact connection. HMEC average diameter 45μm, average height h 0 is 5 μm, the average synapse length l 0 is 10 μm.

[0042] refer to Figure 1 ~ Figure 3 . The three-dimensional single-cell culture chip used for HMEC culture in this embodiment includes circular cavities 1 distributed in an array, and there are microgrooves 3 connected between adjacent cavities 1, and the depth of the microgrooves 3 is the same as that of the cavities 1. The height h is h=7μm; the bottom of cavity 1 contains nano-protrusions; the diameter of cavity 1 The distance between two adjacent cavities 1 is l=80 μm; the micro-grooves 3 are evenly distributed at 90°, and the width of the micro-grooves 3 is a=5 μm.

[0043] In this embodiment, the preparation method of the PDMS-based three-dimensional single-cell culture chip is completed by using MEMS technology and replication ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average height | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com