Electrochemical sensor used for bisphenol A detection

An electrochemical and sensor technology, applied in the field of electrochemical sensors for bisphenol A detection, to achieve the effects of good reproducibility, easy operation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

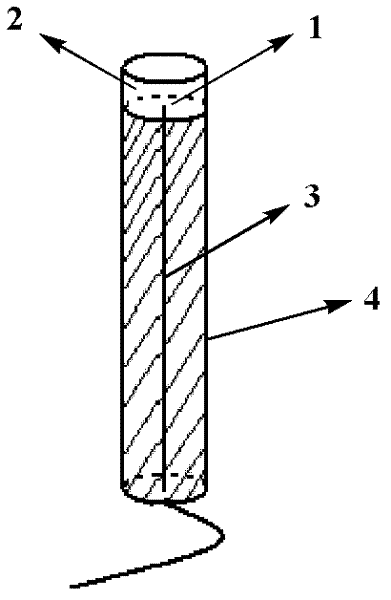

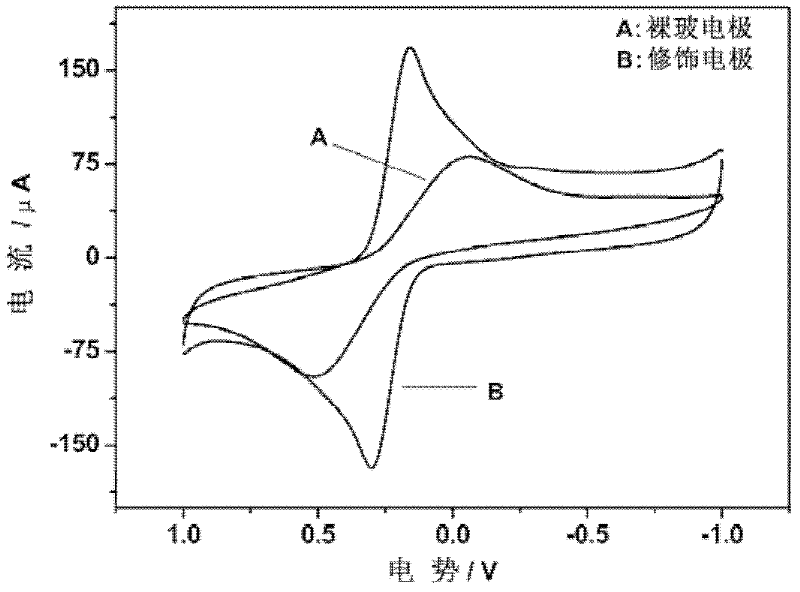

[0054] The electrochemical sensor of the present invention includes glassy carbon electrodes, and a sensitive film is coated on the glassy carbon substrate.

[0055] The preparation method of electrochemical sensor of the present invention is as follows:

[0056] (1) Preparation of mono-(6-hexamethylenediamine)-β-cyclodextrin: add 10 g of hexamethylenediamine and 30 mL of refined DMF to 5 g of mono-(6-p-toluenesulfonyl)-β-cyclodextrin React at 75°C for 4h, settle with acetone, dissolve the precipitate with 10mL water-methanol (volume ratio 3:1), and then settle-dissolve, repeat 5 times and then dry under vacuum at 50°C for 72h to obtain mono-(6-hexyl diamino)-β-cyclodextrin.

[0057] (2) Place 200 mg of dry single-walled carbon nanotubes in a 100 mL round bottom flask, slowly add 20 mL of mixed acid (98% concentrated sulfuric acid and 65% concentrated nitric acid, volume ratio is 3:1) solution, and ultrasonically disperse for 30 min Transfer to a 20°C oil bath for constant t...

Embodiment 2

[0065] Dissolve 1 mg of the prepared carbon nanotube / β-cyclodextrin complex in 2 mL of twice-distilled water, and then disperse it fully by ultrasonic dispersion to obtain a carbon nanotube / β-cyclodextrin complex dispersion , the concentration of the aqueous dispersion is 0.0005mg / L;

[0066] Take 20 μL carbon nanotube / β-cyclodextrin complex dispersion liquid and drop it on the surface of glassy carbon electrode, and the electrochemical sensor covered with sensitive film is obtained after solvent volatilization.

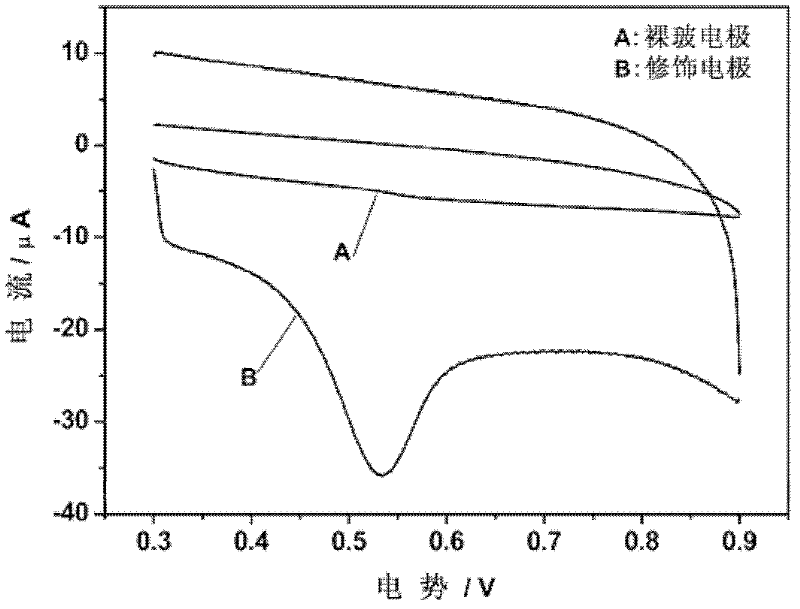

[0067] With the electrochemical sensor gained in the present embodiment to 10 -8 mol / L bisphenol A is detected, and its oxidation peak current is close to that of Example 1.

Embodiment 3

[0069] Dissolve 10 mg of the prepared carbon nanotube / β-cyclodextrin complex in 2 mL of twice-distilled water, and then disperse it fully by ultrasonic dispersion to obtain a carbon nanotube / β-cyclodextrin complex dispersion , the concentration of the aqueous dispersion is 0.005mg / L;

[0070] Take 2 μL carbon nanotube / β-cyclodextrin complex dispersion liquid and drop it on the surface of glassy carbon electrode, and the electrochemical sensor covered with sensitive film is obtained after the solvent evaporates.

[0071] Use this electrochemical sensor for 10 -8 mol / L bisphenol A is detected, and its oxidation peak current is close to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com