Glass plate for solar panel and preparation method for glass plate

A technology of solar panels and glass panels, applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effect of improving corrosion resistance, good wear resistance, and high surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

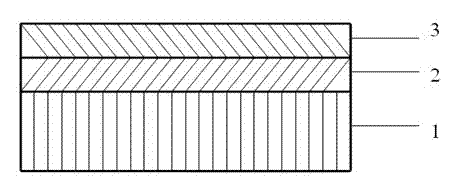

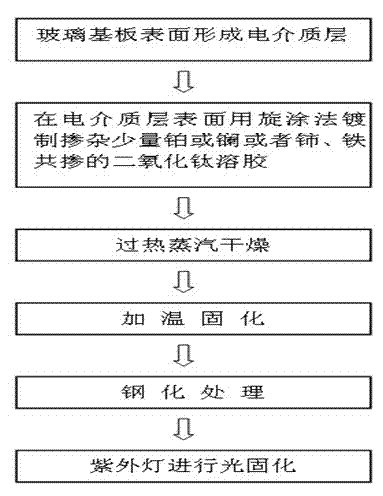

[0044] Plating nano-titanium dioxide film doped with 0.3% platinum on the surface of solar panels

[0045] Using tetrabutyl titanate as the precursor, according to V (Tetrabutyl titanate): V (ethanol): V (Ammonium diacetate) = 170:575:41.25 and mixed continuously for 1 hour to obtain solution A.

[0046] Dissolve a certain amount of H2PtCl6·6H2O in water to make 9ml solution, mix this solution with 200ml absolute ethanol to obtain solution B, slowly add solution B to A, after the dropwise addition, continue to stir for 0.5h, then darken Stand still for 24h to obtain platinum-doped titania sol.

[0047] On the glass surface of the solar cell surface, the dielectric layer is first prepared by vacuum sputtering method to reduce the reflectivity of visible light of the glass. During vacuum sputtering, heat treatment is first carried out on the toughened glass surface at 200 ° C for 0.5 h, and then vacuum sputtering is used in oxygen. A 10nm silicon dioxide dielectric layer is ...

Embodiment 2

[0050] Coating nano-titanium dioxide film doped with 0.3% lanthanum on the surface of solar panels

[0051] Using tetrabutyl titanate as the precursor, according to V (Tetrabutyl titanate): V (ethanol): V (Ammonium diacetate) = 170:575:41.25 and mixed continuously for 1 hour to obtain solution A.

[0052] Dissolve a certain amount of lanthanum nitrate in water to make 9ml solution, mix this solution with 200ml absolute ethanol to obtain solution B, slowly add solution B to A, after the dropwise addition, continue to stir for 0.5h, then Stand in the dark for 24 hours to obtain palladium-doped titania sol.

[0053] On the glass surface of the solar cell surface, the dielectric layer is first prepared by vacuum sputtering method to reduce the reflectivity of visible light of the glass. During vacuum sputtering, heat treatment is first carried out on the toughened glass surface at 200 ° C for 0.5 h, and then vacuum sputtering is used in oxygen. A 10nm silicon dioxide dielectri...

example 3

[0055] Example 3 is coated with a nano-titanium dioxide film doped with 0.1% cerium and 0.02% iron on the surface of a solar panel

[0056] Using tetrabutyl titanate as the precursor, according to V (Tetrabutyl titanate): V (ethanol): V (Ammonium diacetate) = 170:575:41.25 and mixed continuously for 1 hour to obtain solution A.

[0057] Co-dissolve a certain amount of iron nitrate and cerium nitrate in water to make 9ml solution, mix this solution with 200ml absolute ethanol to get solution B, slowly add B solution into A, after the dropwise addition, continue Stir for 0.5h, and then stand in the dark for 24h to obtain platinum-doped titania sol.

[0058] On the glass surface of the solar cell surface, the dielectric layer is first prepared by vacuum sputtering method to reduce the reflectivity of the visible light of the glass. During vacuum sputtering, heat treatment is first performed on the toughened glass surface at 200 ° C for 0.5 h, and then vacuum sputtering is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com