Processed cheese and preparation method thereof

A manufacturing method and a technology for processing cheese, which are applied in dairy products, cheese substitutes, applications, etc., can solve problems such as unreported technology, and achieve the effects of increased product added value, more variety changes, and moderate shell thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

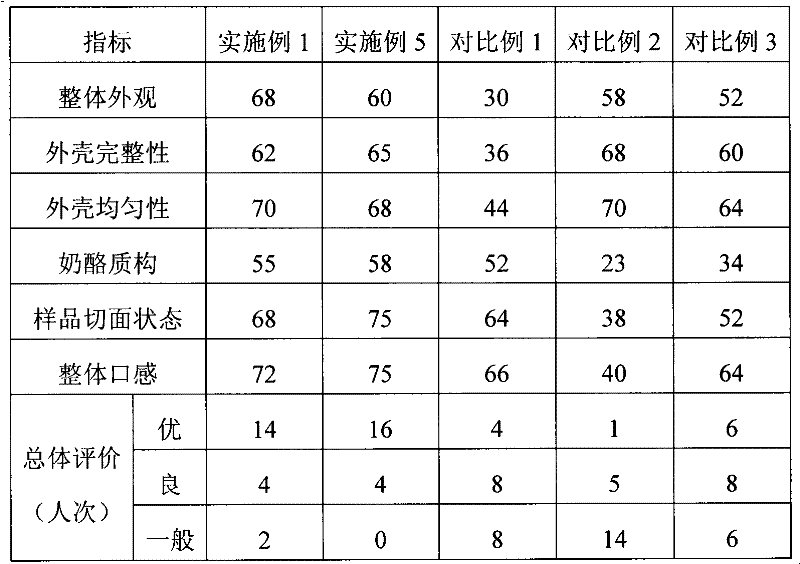

Examples

Embodiment 1

[0046] Raw materials: natural cheese 15%; cream 40%; rennet casein 5%; corn syrup 15%; (emulsifying salt + alcohol ester emulsifier) 2% (sodium citrate 0.2%, sodium tripolyphosphate 1.6 %, monoglyceride 0.1%, Span 60 0.1%); carrageenan 3%; water 20%. Coating size: chocolate coating size.

[0047] Manufacturing method:

[0048] ① Melt and mix the raw materials; shear and mix all the raw materials. The shear rate was 1200 rpm and the melting temperature was 95°C.

[0049]② Homogenize while hot, with a homogenization pressure of 15 MPa; after homogenization, perform conventional pasteurization at a temperature of 93°C for 30 seconds.

[0050] ③ Pour into the mold, the pouring temperature is 90°C, insert the cuttings, cool in ice water for 5 minutes until the core temperature of the cheese drops below 40°C, and mold, then demould.

[0051] ④Spray the surface with liquid nitrogen instantly to reduce the surface temperature to -5°C, coat in a slurry with a temperature of 40°C,...

Embodiment 2

[0053] Raw materials: natural cheese 50%; anhydrous butter 3%; malt syrup 18%; (emulsifying salt + alcohol ester emulsifier) 5% (sodium tripolyphosphate 2.0%, sodium hexametaphosphate 2.5%, lecithin 0.5%) ; Gelatin 0.5%; Water 23.5%. Coating paste: white chocolate coating paste.

[0054] Manufacturing method:

[0055] ① Melt and mix the raw materials; shear and mix all the raw materials. The shear rate was 1500 rpm and the melting temperature was 92°C.

[0056] ② Homogenize while hot, with a homogenization pressure of 10 MPa; after homogenization, perform conventional pasteurization at a temperature of 90°C for 60 seconds.

[0057] ③ Pour into the mold, the pouring temperature is 85°C, insert the cuttings, cool in ice water for 4 minutes until the core temperature of the cheese drops below 40°C, and mold, then demould.

[0058] ④Spray liquid nitrogen on the surface instantly to reduce the surface temperature to -3°C, coat in a slurry with a temperature of 36°C, the coati...

Embodiment 3

[0060] Raw materials: 25% natural cheese; 4% unsalted butter; 10% whole milk powder; 10% sucrose; (emulsified salt + alcohol ester emulsifier) 2.7% (2.4% disodium hydrogen phosphate, sucrose with HLB value 7-16 ester 0.3%); agar 1%; strawberry essence 0.1%; citric acid 1%; water 46.2%. Coating slurry: Strawberry flavored coating slurry.

[0061] Manufacturing method:

[0062] ① Melt and mix the raw materials; shear and mix all the raw materials. The shear rate was 900 rpm and the melting temperature was 85°C.

[0063] ② Homogenize while hot, with a homogenization pressure of 20 MPa; after homogenization, perform conventional pasteurization treatment at a temperature of 85°C for 10 minutes.

[0064] ③ Pour into the mold, the pouring temperature is 80°C, insert the cuttings, cool in the tunnel for 5 minutes until the core temperature of the cheese drops below 40°C, and mold, then demould.

[0065] ④Spray the surface with liquid nitrogen instantaneously to reduce the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com