Filter stick containing tobacco particles and preparation method thereof

A technology of tobacco particles and filter rods, which is applied in the fields of tobacco, e-liquid filter elements, applications, etc., can solve the problems of not being able to increase the aroma of natural tobacco leaves, endangering the health of operators, and weakening the aroma of cigarettes, so as to achieve rich and full tobacco flavor and improve utilization rate , the effect of improving the sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

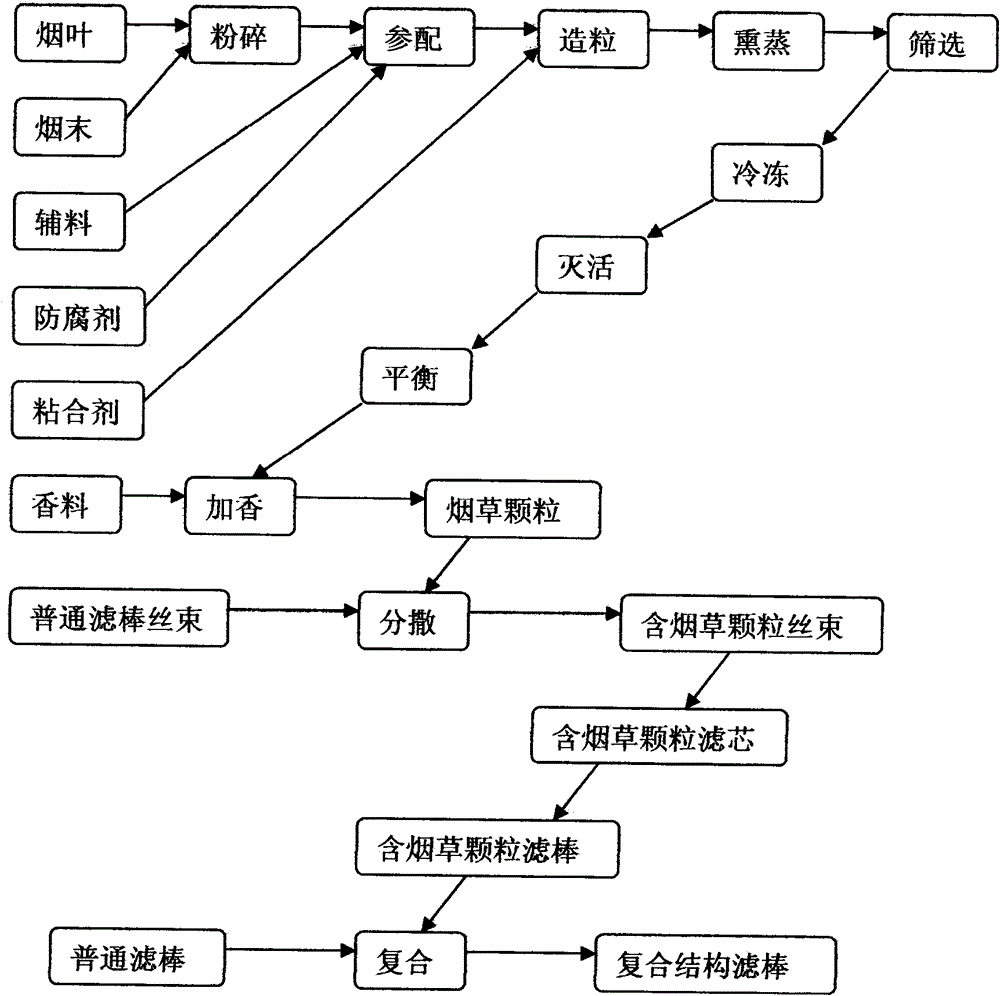

Method used

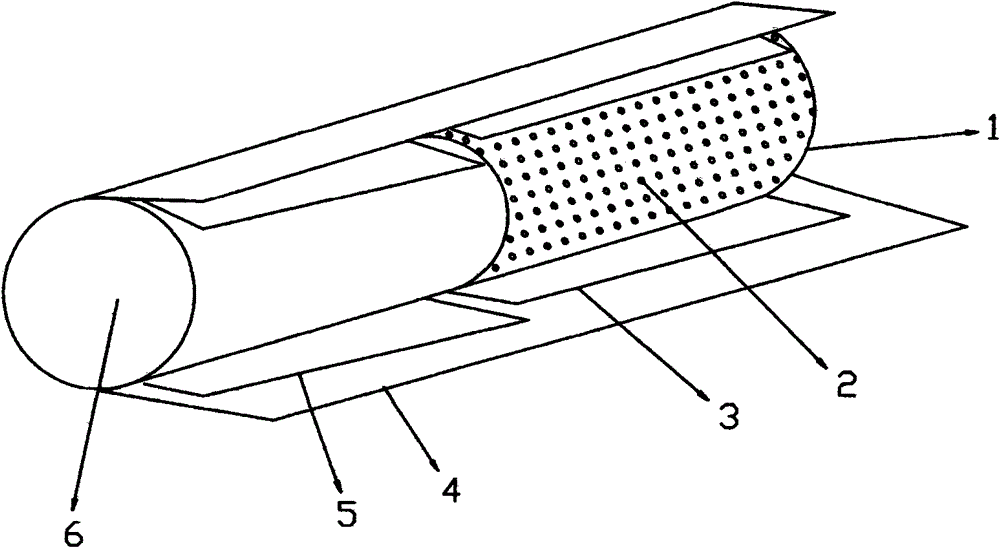

Image

Examples

Embodiment 1

[0039] The dry tobacco leaf and tobacco dust mixture are selected and pulverized by a pulverizer so that the size of the pulverized powder reaches 100-500 mesh. Add 0.01% by weight sodium benzoate preservative and 1% starch auxiliary material to the pulverized raw material powder, put it into a granulator, and then continuously add 0.1% by weight dextrin binder to granulate. After the granulation is completed, fumigate the granules with steam at 150-200°C for 1 hour to remove microorganisms or eggs and form a rich microporous structure inside the granules. When the fumigation is completed, the moisture content of the particles is controlled at about 10%, so as to be close to the moisture content of shredded tobacco. Then sieve the granules, and take 20-50 mesh granules to obtain semi-finished granules.

[0040]The semi-finished granules are placed in an environment of minus 18-20°C for 3 days for freezing treatment, and then placed under ultraviolet light for 10 minutes for i...

Embodiment 2

[0043] The dry tobacco leaf and tobacco dust mixture are selected and pulverized by a pulverizer so that the size of the pulverized powder reaches 100-500 mesh. Add 0.5% by weight of sodium lactate preservative and 30% of titanium dioxide auxiliary materials to the pulverized raw material powder, put it into a granulator, and then continuously add 1% by weight of vinyl acetate binder to granulate. After the granulation is completed, fumigate the granules with steam at 50-100°C for 1.5 hours to remove microorganisms or eggs and form a rich microporous structure inside the granules. When the fumigation is completed, the moisture content of the particles is controlled at about 9%, so as to be close to the moisture content of shredded tobacco. Then sieve the granules, and take 50-100 mesh granules to obtain semi-finished granules.

[0044] The semi-finished granules are placed in an environment of minus 20-23°C for 2 days for freezing treatment, and then placed under infrared ray...

Embodiment 3

[0047] The dry tobacco leaf and tobacco dust mixture are selected and pulverized by a pulverizer so that the size of the pulverized powder reaches 100-500 mesh. Add 1% by weight of hydrogen peroxide preservative and 50% of flour auxiliary materials to the pulverized raw material powder, put it into a granulator, and then continuously add 5% by weight of gum arabic binder to granulate. After granulation, use microwave baking and humidification treatment for 20-200s to remove microorganisms or eggs and form a rich microporous structure inside the granules. When the microwave baking and humidification treatment is completed, the moisture content of the particles is controlled at about 8%, so as to be close to the moisture content of shredded tobacco. Then sieve the granules, and take 50-200 mesh granules to obtain semi-finished granules.

[0048] The semi-finished granules are placed in an environment of minus 25-28°C for 1 day for freezing treatment, and the processed granules ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com