Wood-plastic composite floor

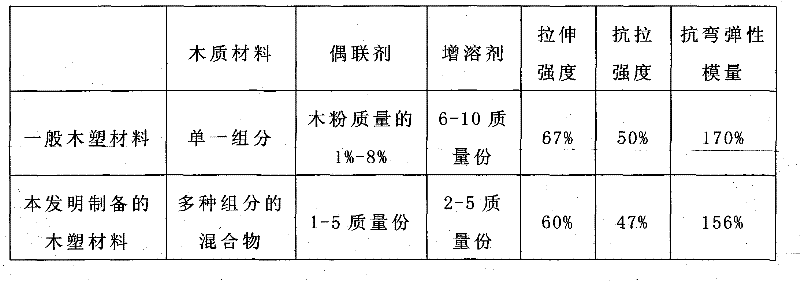

A wood-plastic composite and flooring technology, which is applied in construction, building structure, floor, etc., can solve the problems of adding large additives, and achieve the effects of reducing usage, improving adhesion, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

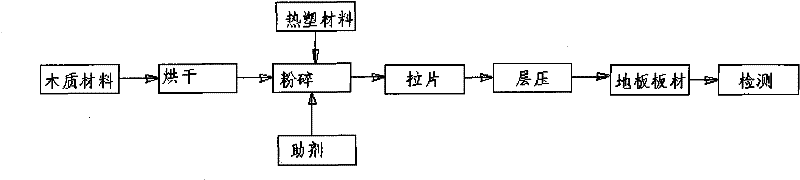

Method used

Image

Examples

Embodiment 1

[0018] A wood-plastic composite floor, characterized in that the components are composed of the following parts by weight:

[0019] Wood pellets 10kg

[0020] Rice husk 5kg

[0021] Carapace 5kg

[0022] Polyethylene 80kg

[0023] The preparation process is as follows:

[0024] Reference figure 1 As shown, the wooden materials are taken in proportion, mixed uniformly, dried at 80°C until the moisture content is below 2.5%, crushed by a grinder so that the particle size is 50 mesh; the thermoplastic materials are mixed and melted after removing impurities, and the wooden material powder is added , 1kg of silane coupling agent and 5kg of ethylene-vinyl acetate copolymer are added, and the finished floor board is obtained after the process of plastic preparation such as drawing and lamination.

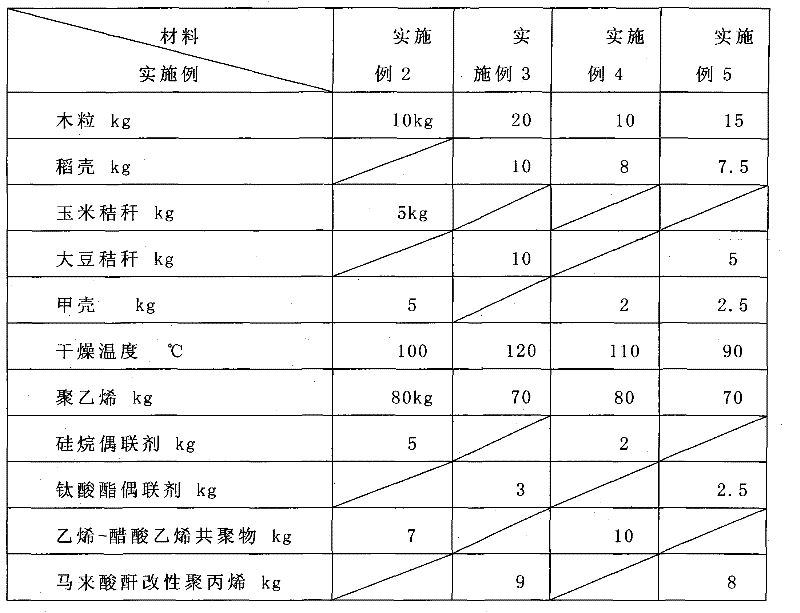

Embodiment 2-5

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com