High-content vitamin C tablets and preparation method thereof

A vitamin and high-content technology, applied in food preparation, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of reduced vitamin C content, shortened shelf life, unstable quality, etc., and achieve long shelf life, convenient production, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

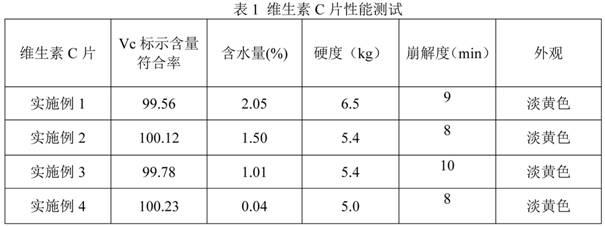

Embodiment 1

[0020] A high-content vitamin C tablet, each of which contains the following components by weight: vitamin C 253mg, vitamin C calcium 147mg, vitamin B 2 0.4mg, Mannitol 200mg, Starch 12mg, Silicon Dioxide 12mg, Magnesium Stearate 6mg.

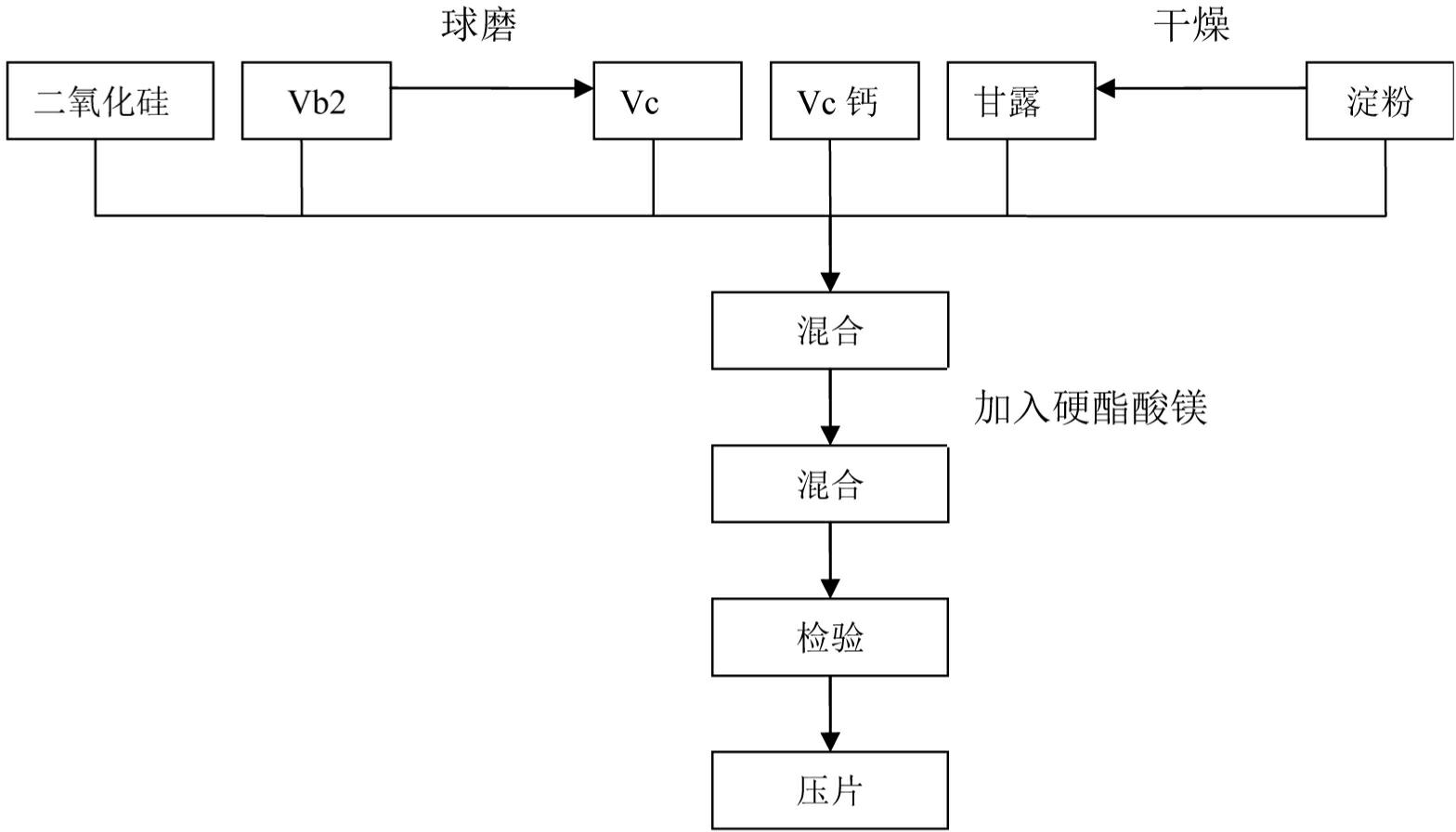

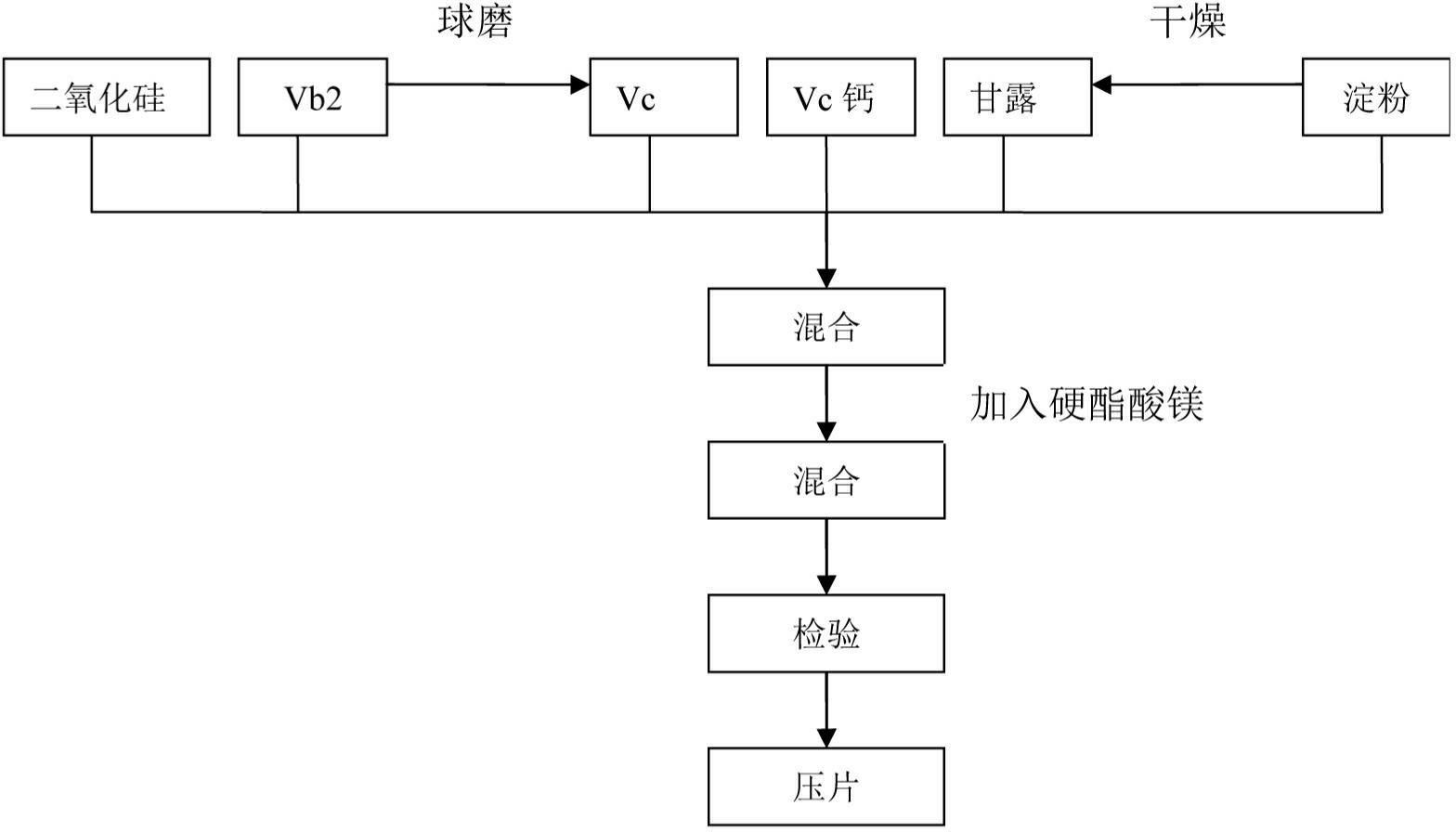

[0021] The preparation method of above-mentioned high-content vitamin C tablet, such as figure 1 , including the following steps:

[0022] 1) The starch was baked at 100°C for 2 hours, and the water content of the starch was measured to be 2%;

[0023] 2) Vitamin B 2 Mill it with silicon dioxide in a ball mill for 1 hour, and pass through a 200-mesh sieve to obtain a mixed powder;

[0024] 3) Pass vitamin C, vitamin C calcium, and mannitol through a 14-mesh sieve, then mix with mixed powder and starch in a three-dimensional mixer for 1 hour, add magnesium stearate and mix for 15 minutes, press into tablets, and pack.

Embodiment 2

[0026] A high-content vitamin C tablet, each of which contains the following components by weight: vitamin C 100mg, vitamin C calcium 80mg, vitamin B 2 0.6mg, mannitol 100mg, starch 10mg, silicon dioxide 6 mg, magnesium stearate 3mg.

[0027] The preparation method of the above-mentioned high-content vitamin C tablet specifically comprises the following steps:

[0028] 1) The starch was baked at 80°C for 4 hours, and the water content of the starch was measured to be 1.5%;

[0029] 2) Vitamin B 2 Mill it with silicon dioxide in a ball mill for 1.5 hours, and pass through a 300-mesh sieve to obtain a mixed powder;

[0030] 3) Pass vitamin C, vitamin C calcium, and mannitol through a 12-mesh sieve, then mix with mixed powder and starch in a three-dimensional mixer for 1 hour, add magnesium stearate and mix for 30 minutes, press into tablets, and pack.

Embodiment 3

[0032] A high-content vitamin C tablet, each of which contains the following components by weight: vitamin C 280mg, vitamin C calcium 200mg, vitamin B 2 0.8mg, Mannitol 230mg, Starch 6mg, Silicon Dioxide 15mg, Magnesium Stearate 8mg.

[0033] The preparation method of the above-mentioned high-content vitamin C tablet specifically comprises the following steps:

[0034] 1) The starch was baked at 120°C for 2 hours, and the water content of the starch was measured to be 1.01%;

[0035] 2) Vitamin B 2 Mill it with silicon dioxide in a ball mill for 2 hours, and pass through a 300-mesh sieve to obtain a mixed powder;

[0036] 3) Pass vitamin C, vitamin C calcium, and mannitol through a 30-mesh sieve, then mix with mixed powder and starch in a three-dimensional mixer for 1.5 hours, add magnesium stearate and mix for 20 minutes, press into tablets, and pack.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com