Metal element modified ZSM-5 molecular sieve composite membrane as well as preparation method and application thereof

A technology of ZSM-5 and metal elements, which is applied in the field of ZSM-5 molecular sieve composite membranes modified by metal elements, to achieve the effect of enhanced selective permeability, good continuity and excellent separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

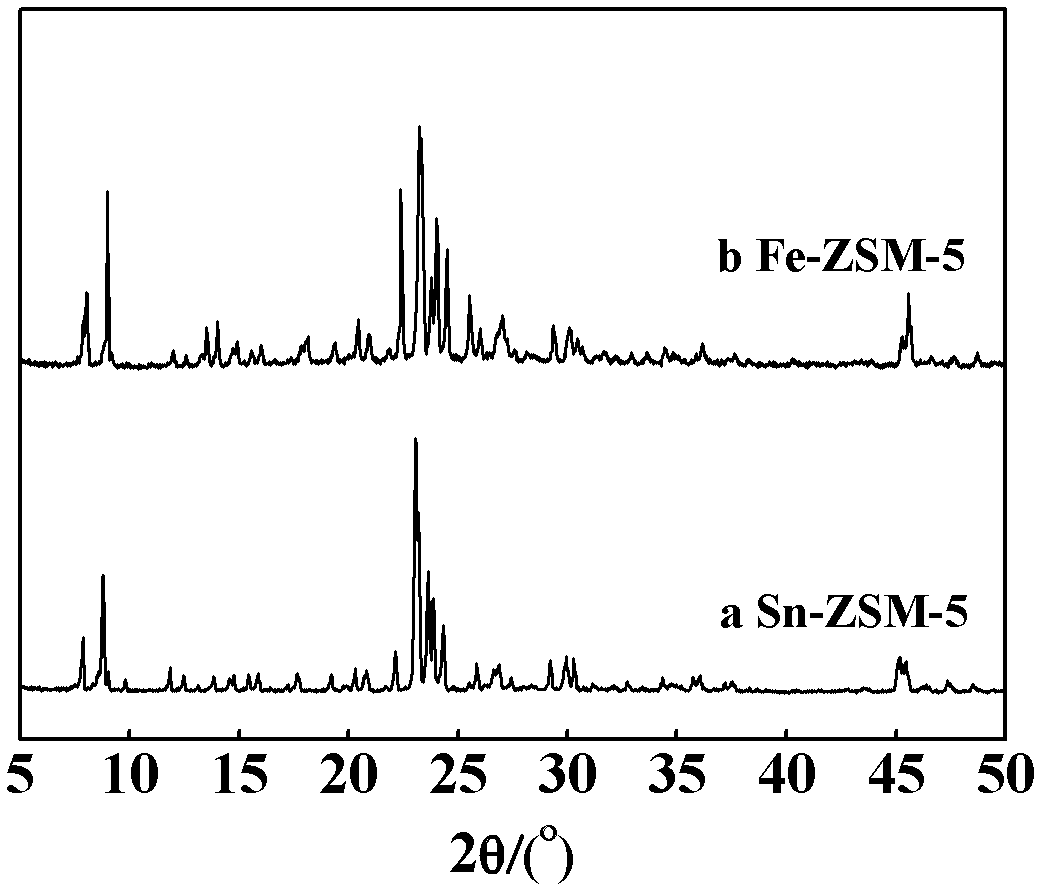

[0036] A certain amount of TPABr, TEOS, sodium hydroxide (NaOH), tin tetrachloride (SnCl 4 ) and deionized water in a certain molar ratio, namely n(NaOH):n(TEOS):n(TPABr):n(SnCl 4 ):n(H 2 (0)=0.3:1:0.3:0.03:60 configure the molecular sieve synthesis liquid. Stir at room temperature for 12 hours, pour into a stainless steel crystallization kettle lined with polytetrafluoroethylene, seal it and place it in an oven at 175°C for crystallization for 36 hours. The reactor was taken out, cooled, rinsed with deionized water, dried, and programmed to heat up to 500°C for 7 hours to obtain the Sn-ZSM-5 molecular sieve, whose XRD spectrum was as follows: figure 1 (a) shown.

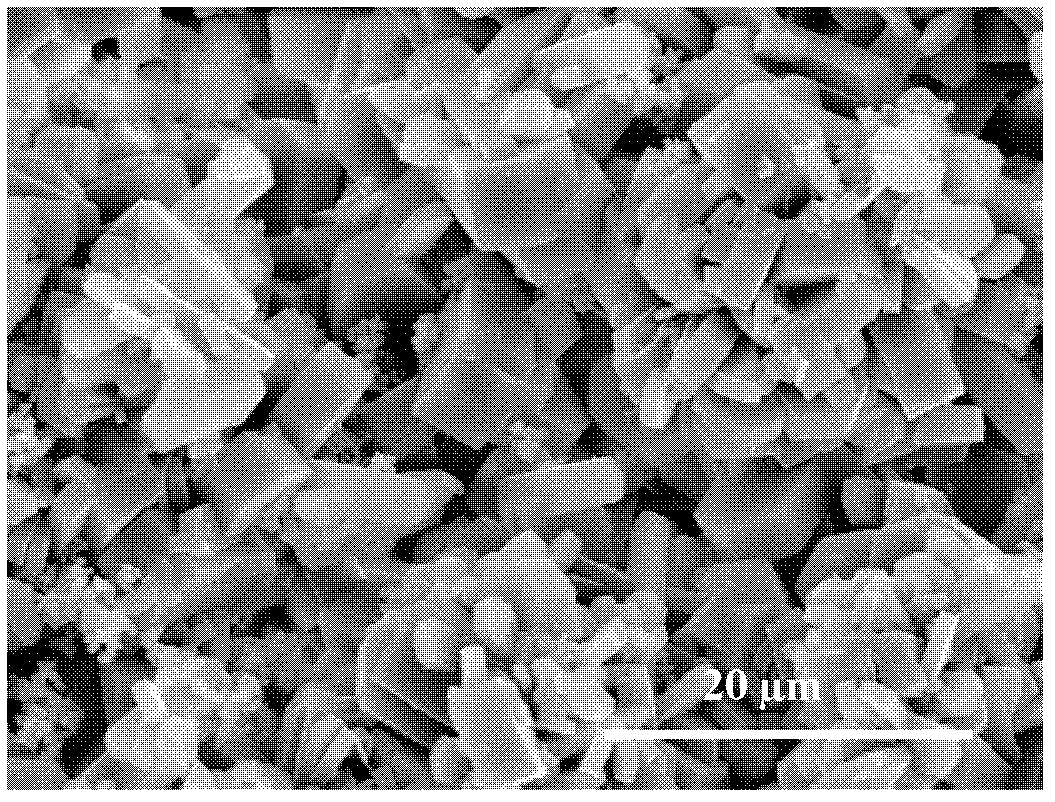

[0037] According to the mass ratio of Sn-ZSM-5 molecular sieve: PDMS: solvent = 1: 0.1: 2, prepare the casting solution, and obtain the casting solution after ultrasonic dispersion for 15 minutes; the casting solution is loaded on the PVC microfiltration membrane by pulling method, Dry at 50°C, and repeat the co...

Embodiment 2

[0039] With water glass (sodium silicate) as silicon source, iron sulfate (FeSO 4 ) is the metal source, EDA is the templating agent, Al 2 SO 3 18H 2 O is the aluminum source, NaOH is the alkali source, and the molar ratio n(NaOH):n(TEOS):n(EDA):n(FeSO 4 ):n(H 2 (0)=0.2:1:0.1:0.05:500 Prepare molecular sieve synthesis solution, age at room temperature for 24 hours, and crystallize in a stainless steel crystallization kettle at 180° C. for 72 hours. Take out the reaction kettle, cool, rinse with deionized water, dry, and heat up to 700 ° C for 7 hours to obtain Fe-ZSM-5 molecular sieve, such as figure 1 (b) shown.

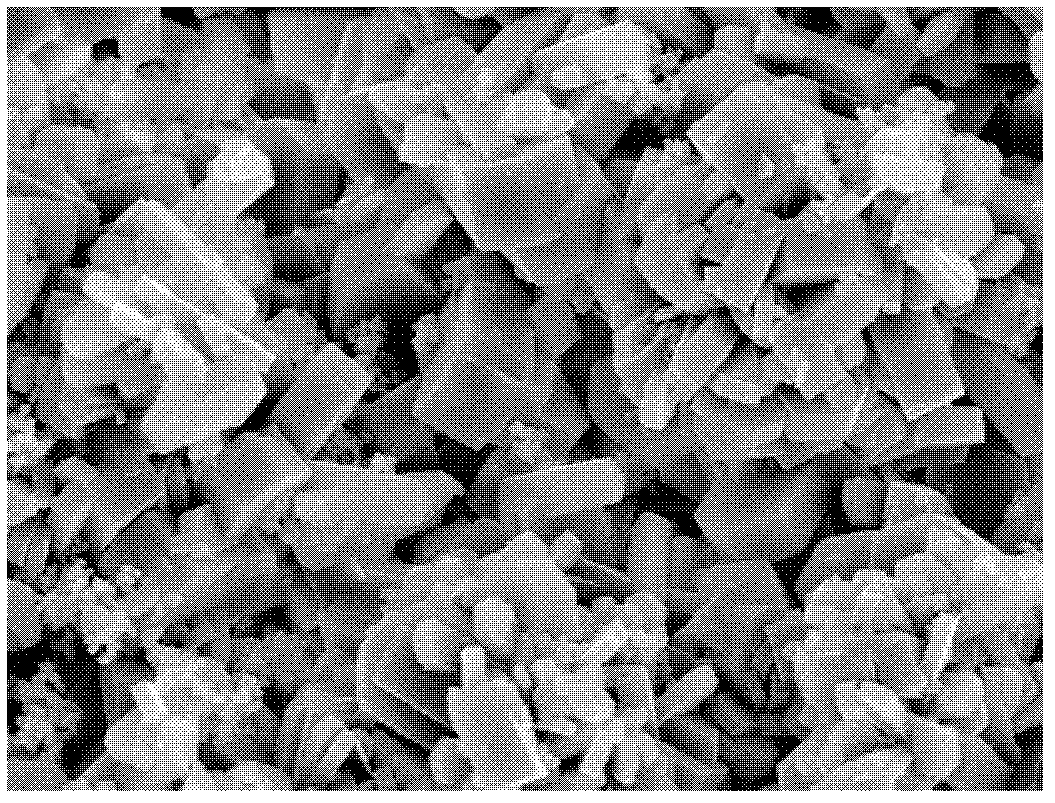

[0040] According to the mass ratio of Fe-ZSM-5 molecular sieve: PDMS: solvent = 1: 0.2: 3, prepare the casting solution, and obtain the casting solution after ultrasonic dispersion for 15 minutes; the casting solution is loaded on the PTFE microfiltration membrane by pulling method, Drying at 60°C and repeat coating three times to obtain a complete Fe-ZSM-5 mo...

Embodiment 3

[0042] Using water glass as silicon source, magnesium nitrate (Mg(NO 3 ) 2 ) is the metal source, EDA is the templating agent, Al 2 SO 3 18H 2 O is the aluminum source, NaOH is the alkali source, and the molar ratio n(NaOH):n(TEOS):n(EDA):n(Mg(NO 3 ) 2 ):n(H 2 (0)=0.2:1:0.1:0.1:600 Prepare molecular sieve synthesis solution, age at room temperature for 24 hours, and crystallize in a stainless steel crystallization kettle at 180° C. for 80 hours. The reactor was taken out, cooled, rinsed with deionized water, dried, programmed to heat up to 600° C. and calcined for 7 hours to obtain Mg-ZSM-5 molecular sieve.

[0043] According to the mass ratio of Mg-ZSM-5 molecular sieve: PDMS: solvent = 1: 0.2: 3, prepare the casting solution, and obtain the casting solution after ultrasonic dispersion for 15 minutes; the casting solution is loaded on the PTFE microfiltration membrane by pulling method, Dry at 60°C and repeat coating three times to obtain a complete Mg-ZSM-5 molecula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com