Method for continuously and efficiently preparing methyl ethyl ketone

A methyl ethyl ketone, high-efficiency technology, applied in 2 fields, can solve problems such as short life, easy carbon deposition, strong corrosion of sulfuric acid catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

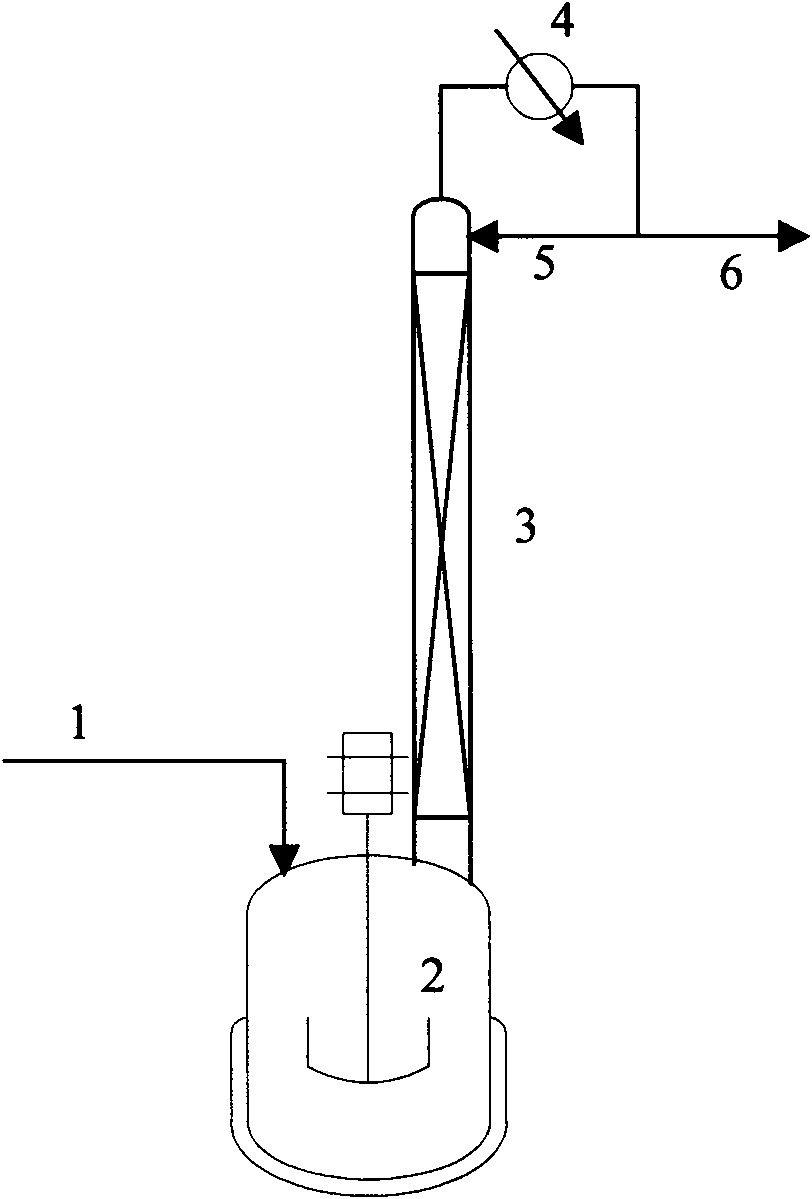

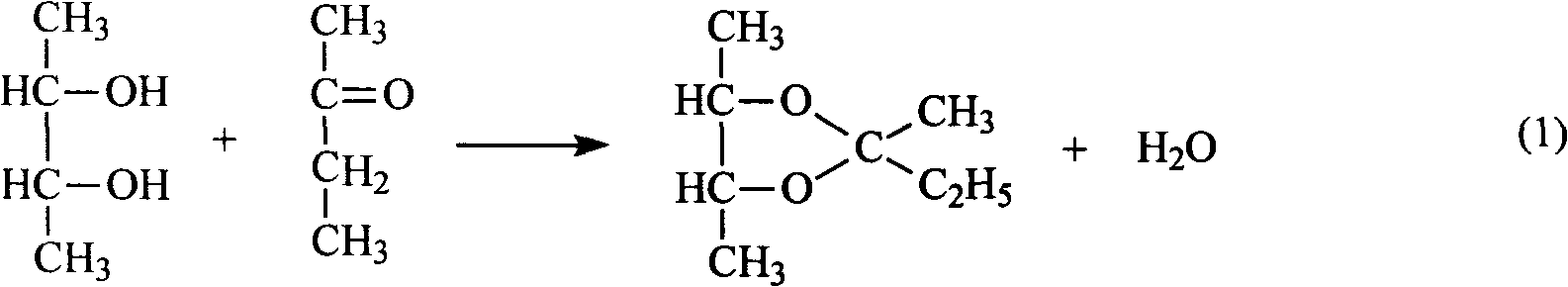

Method used

Image

Examples

Embodiment 1

[0032] The 1000ml four-neck flask is connected with a glass rectification tower with an inner diameter of 35mm and a 1m stainless steel θ filler inside. There is a condenser and a reflux distributor at the top of the tower. Add 5 grams of p-toluenesulfonic acid in the flask, adopt magnetic stirrer to stir, control temperature 165 ℃ with intelligent electric heating mantle, continuously pump into the 2,3-butanediol solution of 80% (wt) content with metering pump, The feed rate is 10ml / min, the overhead reflux ratio is adjusted to be 1:1, and the overhead distillation temperature is 70-80°C. The top discharge was analyzed by gas chromatography and quantified by the internal standard method. Through analysis and calculation, the conversion rate of 2,3-butanediol is 97%, the selectivity of methyl ethyl ketone is 96%, and the yield is 93.1%.

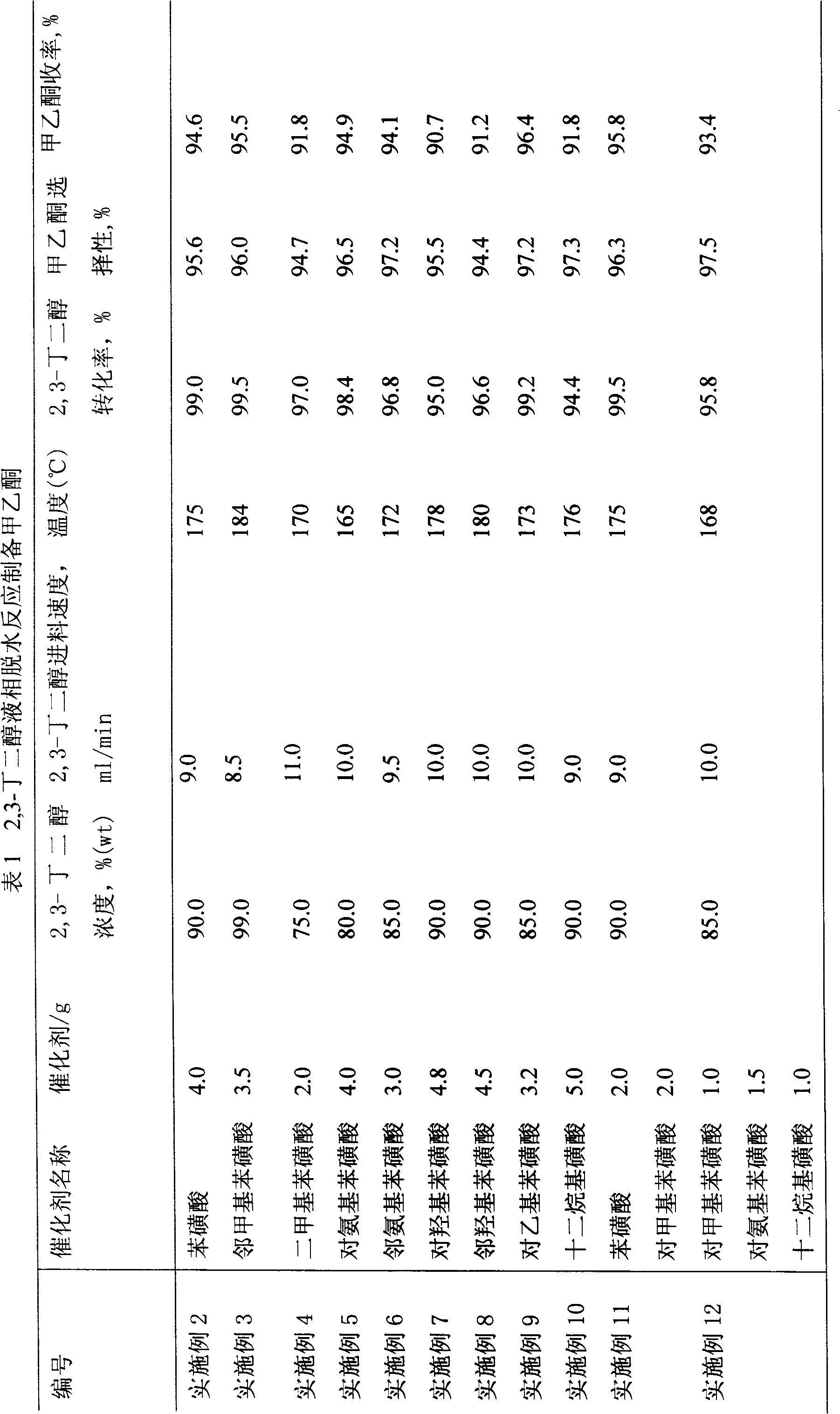

Embodiment 2~12

[0034] The same as Example 1, 2,3-butanediol was dehydrated under different catalysts and different reaction conditions, and the results are shown in Table 1.

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com