Method for producing acetylene through joint producing ethene by natural gas pyrolysis method

A technology of natural gas and acetylene, which is applied in the field of acetylene production and co-production of ethylene by cracking natural gas to produce acetylene. It can solve the problems of high reaction temperature and high energy consumption, and achieve the effects of reducing costs, shortening mixing time, and making up for the loss of acetylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

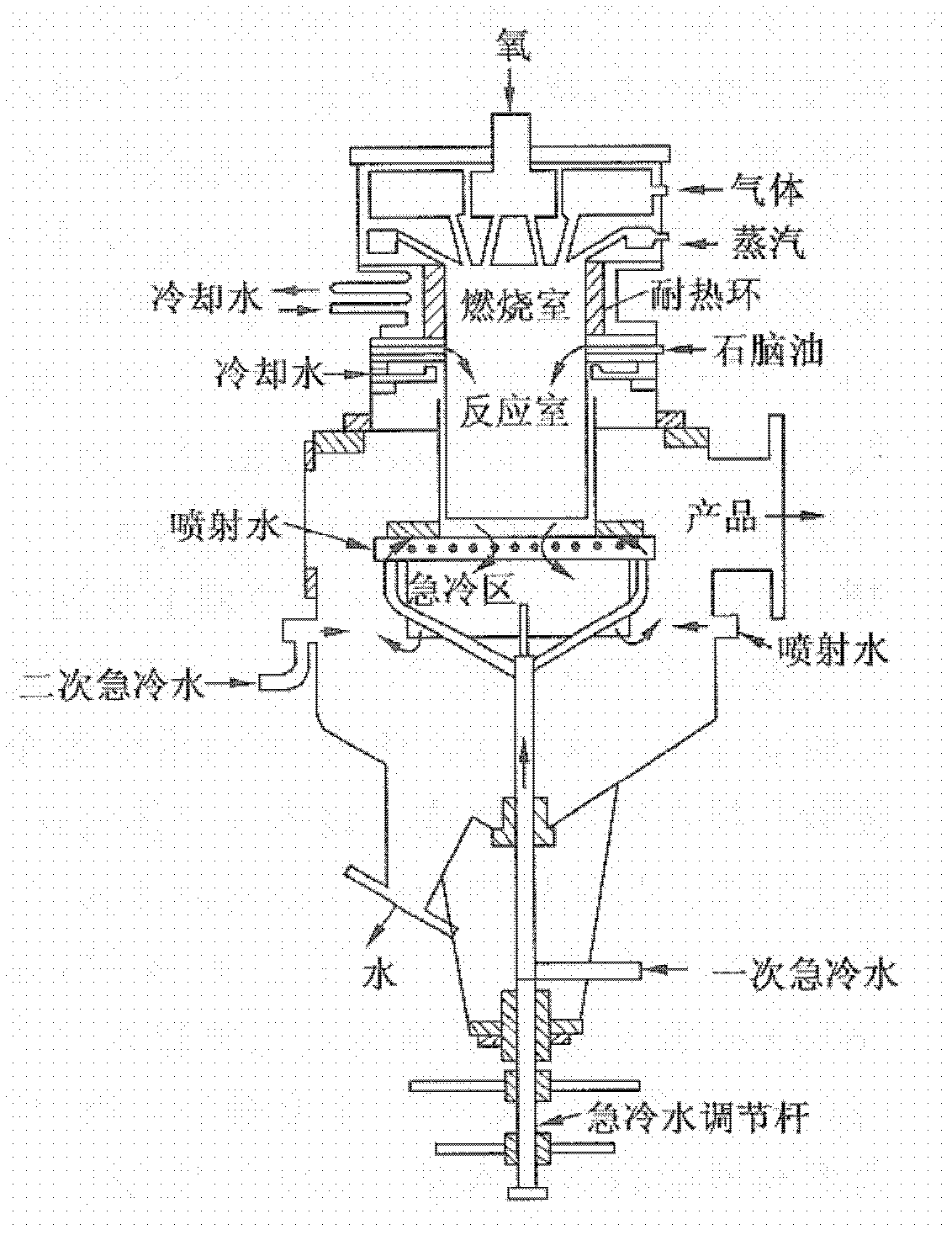

Image

Examples

Embodiment 1

[0012] In metal materials, liquid nitrogen is used to concentrate acetylene, and the machine is driven to normal operation for 5 minutes. There is a water film on the side wall of the reaction zone to wet the reactor wall along the direction of air flow. The mixing chamber is multi-tube type, and each mixing tube is connected to a nozzle. Therefore, the mixing time is shortened and the preheating temperature of the raw material can be increased to 700 ℃.

Embodiment 2

[0014] In metal materials, liquid nitrogen is used to concentrate acetylene, and the machine is driven to normal operation for 10 minutes. There is a water film on the side wall of the reaction zone to wet the reactor wall along the air flow direction. The mixing chamber is multi-tube type, and each mixing tube is connected to a nozzle. Therefore, the mixing time is shortened and the preheating temperature of the raw material can be increased to 900 °C.

Embodiment 3

[0016] In metal materials, liquid nitrogen is used to concentrate acetylene, and the machine is driven to normal operation for 8 minutes. There is a water film on the side wall of the reaction zone to wet the reactor wall along the direction of air flow. The mixing chamber is multi-tube type, and each mixing tube is connected to a nozzle. Therefore, the mixing time is shortened, allowing the preheating temperature of the raw material to be increased to 750°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sublimation point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com