Manufacturing method for distributed-feedback semiconductor laser with bar-shaped burying

A technology of distributed feedback and manufacturing methods, which is applied to semiconductor lasers, lasers, laser components, etc., and can solve problems such as complex processes and unreliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate a further understanding of the method and the achieved effects of the present invention, the preferred embodiments are described in detail below in conjunction with the drawings.

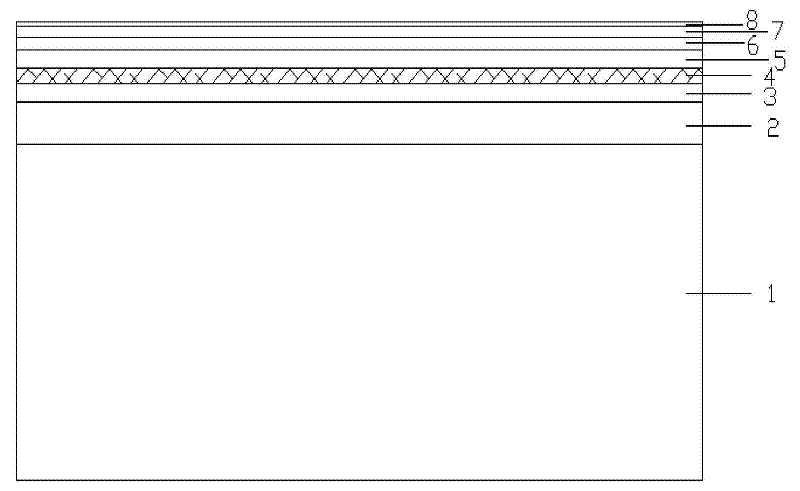

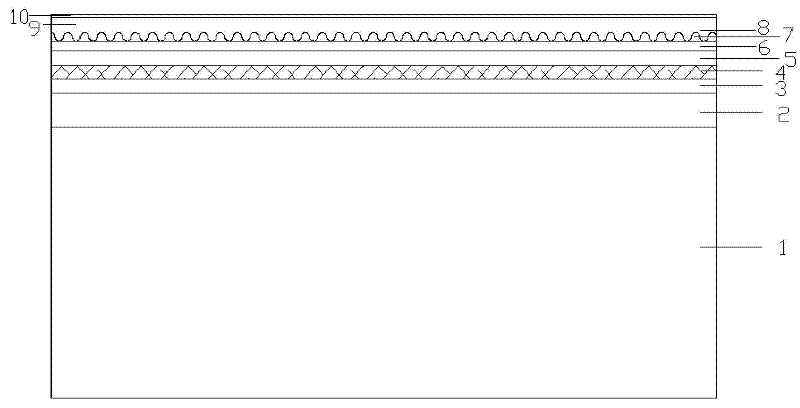

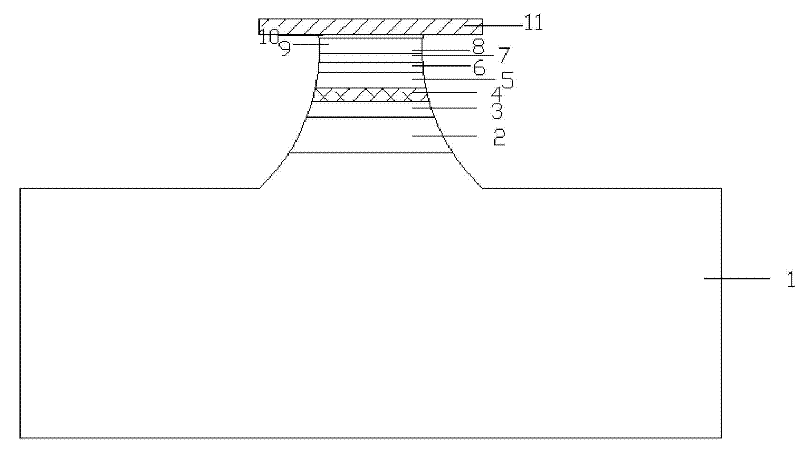

[0029] Please refer to Figure 1 to Figure 6 As shown, the present invention is the multi-layer heterostructure / strained multi-quantum well epitaxial layer required for the epitaxial growth of the laser on the N-type indium phosphide (InP) substrate, which is the primary epitaxial wafer; and then on the basis of the primary epitaxial wafer Fabrication of distributed feedback Bragg gratings, fabrication of ridge strip structures by dry etching and two-step wet etching, and implementation of SiO 2 (Silicon dioxide) cantilever; after special treatment by MOVCD (Metal-organic Chemical Vapor Deposition, metal organic compound chemical vapor deposition), ridge strip burial, etc.

[0030] Below with reference to accompanying drawing, introduce each step of method of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com