Method for producing organic fertilizer by using activated sludge

A technology of activated sludge and organic fertilizer, applied in the biological field, can solve problems such as long fermentation time, achieve quick results, increase the number of beneficial bacteria, and purify the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

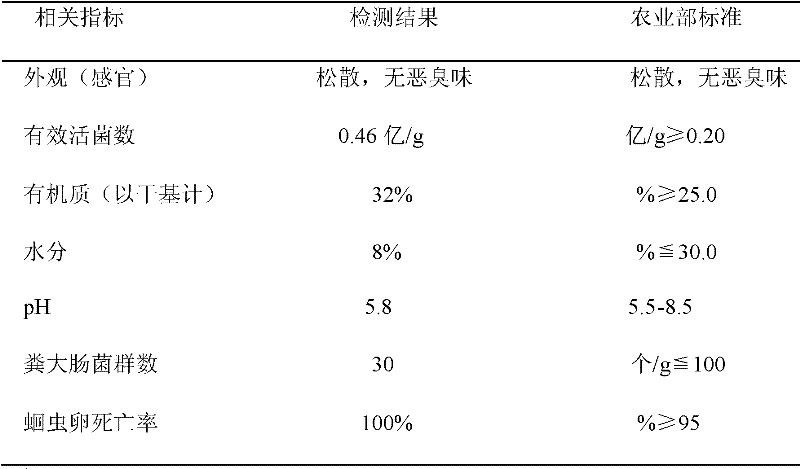

Image

Examples

Embodiment 1

[0018] Add biological bacteria solution and enzyme preparation to 1 kg of activated sludge. Biological bacteria liquid, which contains the following components: Bacillus licheniformis, Bacillus megaterium, Bacillus natto, Bacillus subtilis, Lactobacillus plantarum and Lactobacillus delbrueckii subsp. 1.5%. Among them, the bacterial concentration of Bacillus licheniformis, Bacillus megaterium, Bacillus natto, Bacillus subtilis, Lactobacillus plantarum and Lactobacillus delbrueckii subsp. 8 pcs / ml to 8×10 8 pieces / ml. Adding a mixed enzyme preparation with a mass ratio of 1%, the enzyme preparation is composed of: amylase (200000u / g), cellulase (200000u / g), lipase (100000u / g), protease (100000u / g), fat Enzyme (100000u / g), pectinase (100000u / g), glucoamylase (200000u / g).

[0019] The composition mass ratio of the enzyme preparation is amylase: cellulase: lipase: protease: pectinase: glucoamylase is 0.8: 1.0: 0.8: 1.0: 0.8: 0.6.

[0020] Put the activated sludge added with bi...

Embodiment 2

[0033]Add biological bacteria solution and enzyme preparation to 1 kg of activated sludge. Biological bacteria liquid, which contains the following components: Bacillus licheniformis, Bacillus megaterium, Bacillus natto, Bacillus subtilis, Lactobacillus plantarum and Lactobacillus delbrueckii subsp. 4.8%. Among them, the bacterial concentration of Bacillus licheniformis, Bacillus megaterium, Bacillus natto, Bacillus subtilis, Lactobacillus plantarum and Lactobacillus delbrueckii subsp. 8 pcs / ml to 8×10 8 pieces / ml. Adding a mixed enzyme preparation with a mass ratio of 3%, the enzyme preparation is composed of: amylase (200000u / g), cellulase (200000u / g), lipase (100000u / g), protease (100000u / g), fat Enzyme (100000u / g), pectinase (100000u / g), glucoamylase (200000u / g).

[0034] The composition mass ratio of the enzyme preparation is amylase: cellulase: lipase: protease: pectinase: glucoamylase is 1.0:1.0:0.9:1.1:1.1:0.7.

[0035] Put the activated sludge added with biologic...

Embodiment 3

[0041] Add biological bacteria solution and enzyme preparation to 1 kg of activated sludge. Biological bacteria liquid, which contains the following components: Bacillus licheniformis, Bacillus megaterium, Bacillus natto, Bacillus subtilis, Lactobacillus plantarum and Lactobacillus delbrueckii subsp. 7.5%. Among them, the bacterial concentration of Bacillus licheniformis, Bacillus megaterium, Bacillus natto, Bacillus subtilis, Lactobacillus plantarum and Lactobacillus delbrueckii subsp. 8 pcs / ml to 8×10 8 pieces / ml. Adding a mixed enzyme preparation with a mass ratio of 6%, the enzyme preparation is composed of: amylase (200000u / g), cellulase (200000u / g), lipase (100000u / g), protease (100000u / g), fat Enzyme (100000u / g), pectinase (100000u / g), glucoamylase (200000u / g).

[0042] The composition mass ratio of the enzyme preparation is amylase: cellulase: lipase: protease: pectinase: glucoamylase is 1.2: 1.2: 1.0: 1.4: 1.2: 0.8.

[0043] Put the activated sludge added with bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com