Fluorine-containing modified vegetable oil polymer water-repellent finishing agent, and preparation and application thereof

A technology for modified vegetable oil and water-repellent finishing, applied in the field of fluorine-containing modified vegetable oil polymer water-repellent finishing agent and its preparation and application fields, can solve the problem that the fabric is prone to static electricity, the effect of cellulose fiber wearability, and the affinity of cellulose fiber. Water quality reduction and other issues, to achieve the effects of low cost, low environmental pollution, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

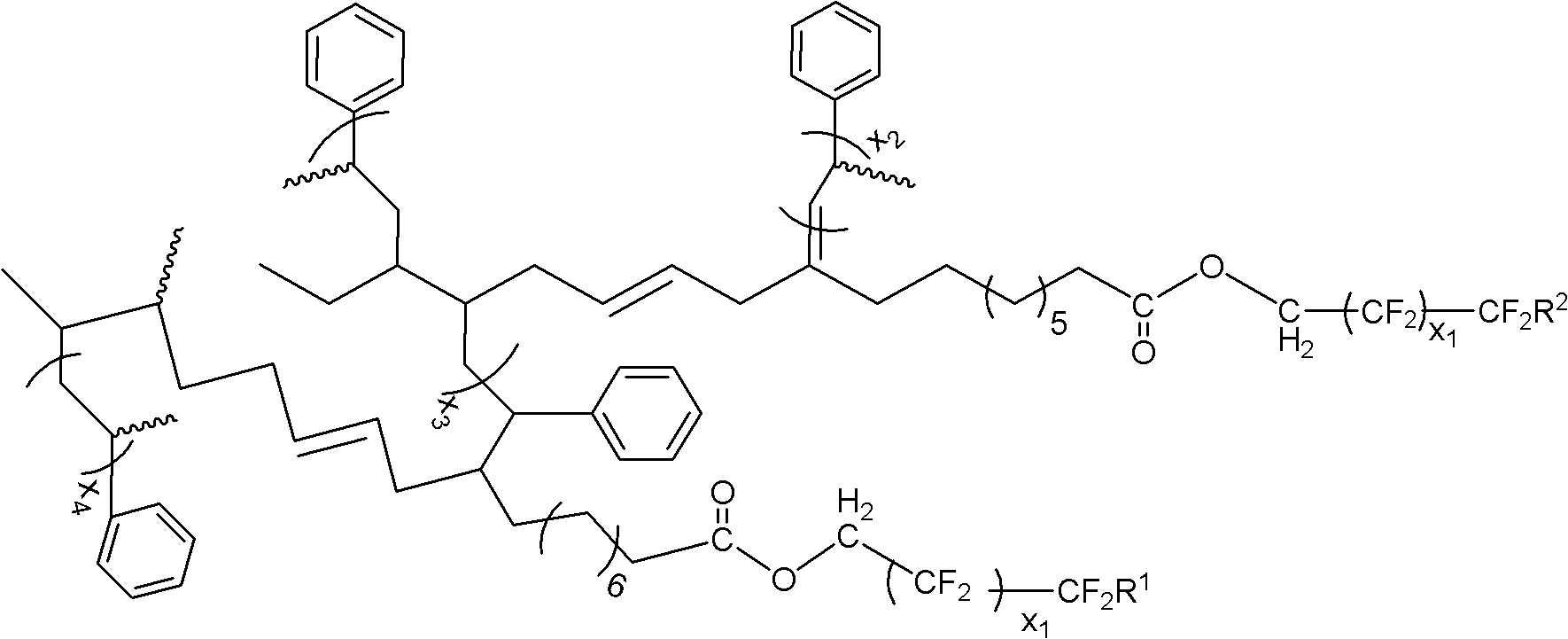

Image

Examples

Embodiment 1

[0037] (1) Add 30 mL of absolute ethanol solution and 0.15 mol of sodium hydroxide solution to 29 g of linseed oil, heat in an oil bath at 120° C., stir, and let stand. Heat to remove absolute ethanol. Add 20-30mL of hot saturated sodium chloride solution to precipitate the mixture of sodium linolenate, sodium soybeanate, sodium stearate, sodium oleate, sodium linoleate and sodium linolenate, and remove glycerin with the aqueous sodium chloride solution.

[0038] (2) The mixture of sodium stearate, sodium oleate, sodium linoleate and sodium linolenate prepared in step (1) is acidified by adding 5-10mL1mol / L dilute sulfuric acid to obtain stearic acid, oleic acid, linolenic acid A mixture of oleic and linolenic acids.

[0039] (3) 23g of the mixture of stearic acid, oleic acid, linoleic acid and linolenic acid prepared in step (2) was added to CF containing 0.1mol 3 CH 2 In a three-necked OH bottle, heat up to 60°C, stir, and react for 6 hours to obtain a mixture of trifluor...

Embodiment 2

[0044] (1) Add 30 mL of absolute ethanol solution and 0.15 mol of sodium hydroxide solution to 35 g of soybean oil, heat in an oil bath at 120° C., stir, and let stand. Heat to remove absolute ethanol. Add 20-30mL hot saturated sodium chloride solution to precipitate the mixture of sodium soybean oleate, sodium stearate and sodium oleate, and remove the glycerin with the aqueous sodium chloride solution.

[0045] (2) The mixture of sodium stearate, sodium oleate, and sodium soyate prepared in step (1) is acidified by adding 5 mL of 1mol / L dilute sulfuric acid to obtain a mixture of stearic acid, oleic acid, and soybean acid.

[0046] (3) 21 g of the mixture of stearic acid and oleic acid soybean acid prepared in step (2) is added to CF containing 0.1 mol 3 CH 2 CH 2 In an OH three-necked flask, heat up to 60°C, stir and react for 6 hours to obtain a mixture of fluorine-containing esters.

[0047] (4) Stir and react the fluorine-containing ester prepared in step (3) with 10...

Embodiment 3

[0052] (1) Add 30 mL of absolute ethanol solution and 0.15 mol of sodium hydroxide solution to 30 g of olive oil, heat in an oil bath at 120° C., stir, and let stand. Heat to remove absolute ethanol. Add 20-30mL hot saturated sodium chloride solution to precipitate the mixture of sodium stearate, sodium linoleate and sodium linolenate, and remove the glycerin with the aqueous sodium chloride solution.

[0053] (2) The mixture of sodium stearate, sodium linoleate, and linolenic acid prepared in step (1) is acidified by adding 5 mL of 1mol / L dilute sulfuric acid to obtain a mixture of stearic acid, linoleic acid, and linolenic acid.

[0054] (3) 25g of the mixture of stearic acid, linoleic acid and linolenic acid prepared in step (2) is added to the CF containing 0.1mol 3 (CH 2 ) 2 CH 2 In an OH three-necked flask, heat up to 60°C, stir and react for 6 hours to obtain a mixture of fluorine-containing esters.

[0055] (4) Stir and react the fluorine-containing ester prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com