Dairy cattle concentrate supplement and preparation method thereof

A concentrate supplement and dairy cow technology, applied in the field of dairy cow concentrate supplement and its preparation, can solve problems such as increased breeding costs, abnormal digestive function, increased excretion of nutrients and their metabolites, etc., to achieve increased milk production and Milk quality, precise balance of nutrient supply and demand, and the effect of reducing digestive disorders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

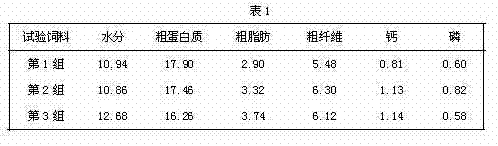

Examples

Embodiment 1

[0026] The formula of milk cow concentrate supplementary material of the present invention is as follows:

[0027] Corn 500kg, soybean meal 80kg, cottonseed meal 60kg, rapeseed meal 50kg, flax cake 70kg, calcium carbonate 15kg, calcium hydrogen phosphate 12kg, salt 10kg, sodium diacetate 8kg, baking soda 12kg, magnesium oxide 8kg, slow-release non-protein Nitrogen 5kg, mineral premix 20kg, multivitamin premix 10kg, corn gluten powder 30kg, DDGS 40kg, wheat bran 70kg;

[0028] Each 100kg of mineral premix contains: ferrous sulfate 15g, copper sulfate 18g, manganese sulfate 17g, zinc sulfate 115g, potassium chloride 150g, potassium iodide 11g, sodium selenite 8g, cobalt chloride 36g, zeolite powder 50kg , Medical stone 49.63kg; Among them,

[0029] Each 1kg mineral premix contains: Iron 25mg-50mg, Copper 30mg-60mg, Manganese 35mg-70mg, Zinc 280mg-500mg, Potassium 500mg-1000mg, Iodine 70mg-100mg, Selenium 30mg- 50mg, cobalt element 50mg-100mg.

[0030] The composition of every...

Embodiment 2

[0091] The formula of milk cow concentrate supplementary material of the present invention is as follows:

[0092] Corn 470kg, soybean meal 100kg, cottonseed meal 130kg, rapeseed meal 40kg, flax cake 70kg, calcium carbonate 20kg, calcium hydrogen phosphate 10kg, salt 3kg, sodium diacetate 5kg, baking soda 4kg, magnesium oxide 2kg, slow-release non-protein Nitrogen 6kg, mineral premix 20kg, multivitamin premix 10kg, corn gluten powder 30kg, DDGS 30kg, wheat bran 50kg;

[0093] Wherein the composition of the mineral premix and the composition of the multivitamin premix are the same as in Example 1.

[0094] The preparation method of the milk cow concentrate supplement of the present invention is the same as that of Example 1.

Embodiment 3

[0096] The formula of milk cow concentrate supplementary material of the present invention is as follows:

[0097] Corn 450kg, soybean meal 50kg, cottonseed meal 60kg, rapeseed meal 40kg, flax cake 89kg, calcium carbonate 30kg, calcium hydrogen phosphate 20kg, salt 5kg, sodium diacetate 10kg, baking soda 24kg, magnesium oxide 12kg, slow-release non-protein Nitrogen 10kg, mineral premix 40kg, multivitamin premix 20kg, corn gluten powder 45kg, DDGS 45kg, wheat bran 50kg;

[0098] Wherein the composition of the mineral premix and the composition of the multivitamin premix are the same as in Example 1.

[0099] The preparation method of the milk cow concentrate supplement of the present invention is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com