Nano-grade-silver-filled room-temperature-cured conductive adhesive

A room temperature curing, nano-silver technology, applied in the direction of conductive adhesives, adhesives, epoxy glue, etc., can solve the problems of high viscosity and weakened mechanical properties, and achieve the reduction of silver filling, the improvement of mechanical properties and the reduction of cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

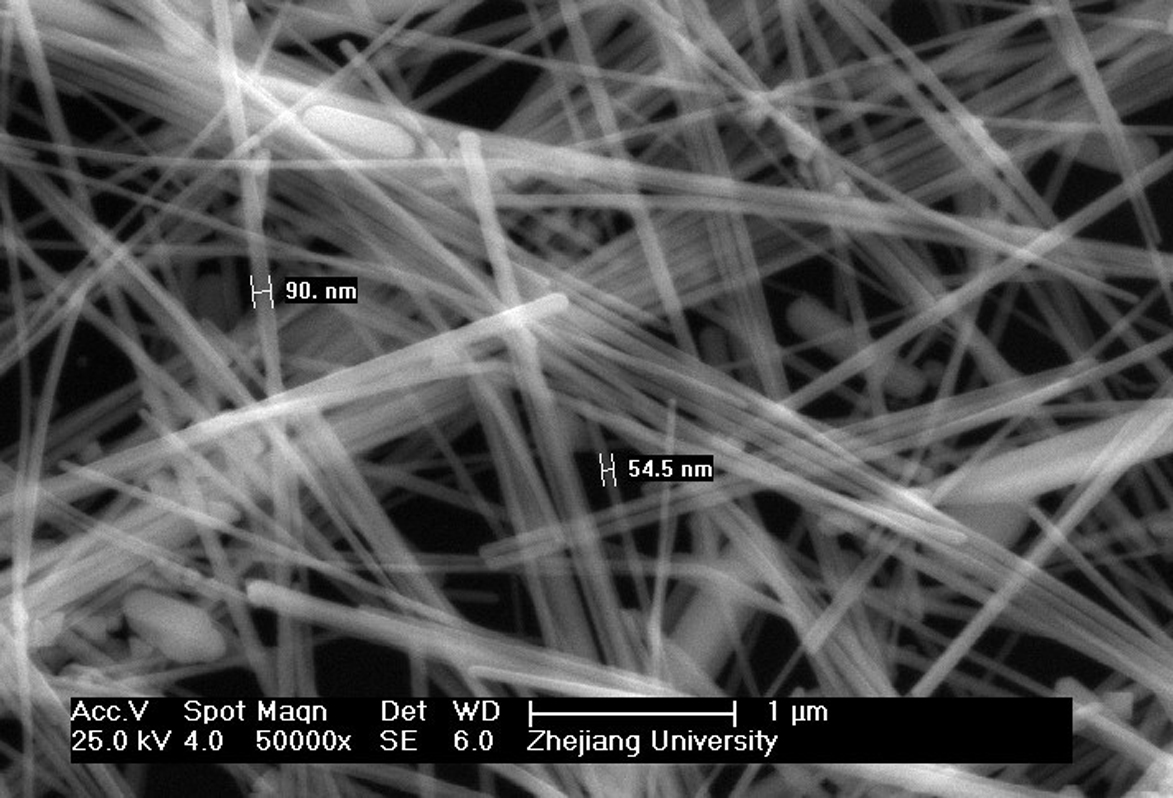

[0039]According to the mass ratio of 1:1, mix 10g silver nitrate and 10g PVP into a beaker filled with 500g ethylene glycol, and stir ultrasonically to obtain a uniform and transparent solution; prepare a solution reaction system containing silver ions; add to the solution containing silver ions Add 100 mg of sodium chloride to the reaction system, stir evenly to obtain a reaction precursor; put the prepared suspension into a microwave oven, and the reaction conditions are: 320W, 20min. Add water to the reacted solution, centrifuge at 2000 rpm for 20 minutes to obtain a precipitate, then wash with deionized water, absolute ethanol or acetone three to four times, and dry at regular temperature to obtain solid silver nanowire powder. The scanning electron microscope test sample is to stick the sample on the aluminum base sample stage, figure 1 The SEM photo of the silver nanowires obtained according to Example 1 is given, the nanowire diameter is about 100nm, and the aspect rati...

Embodiment 2

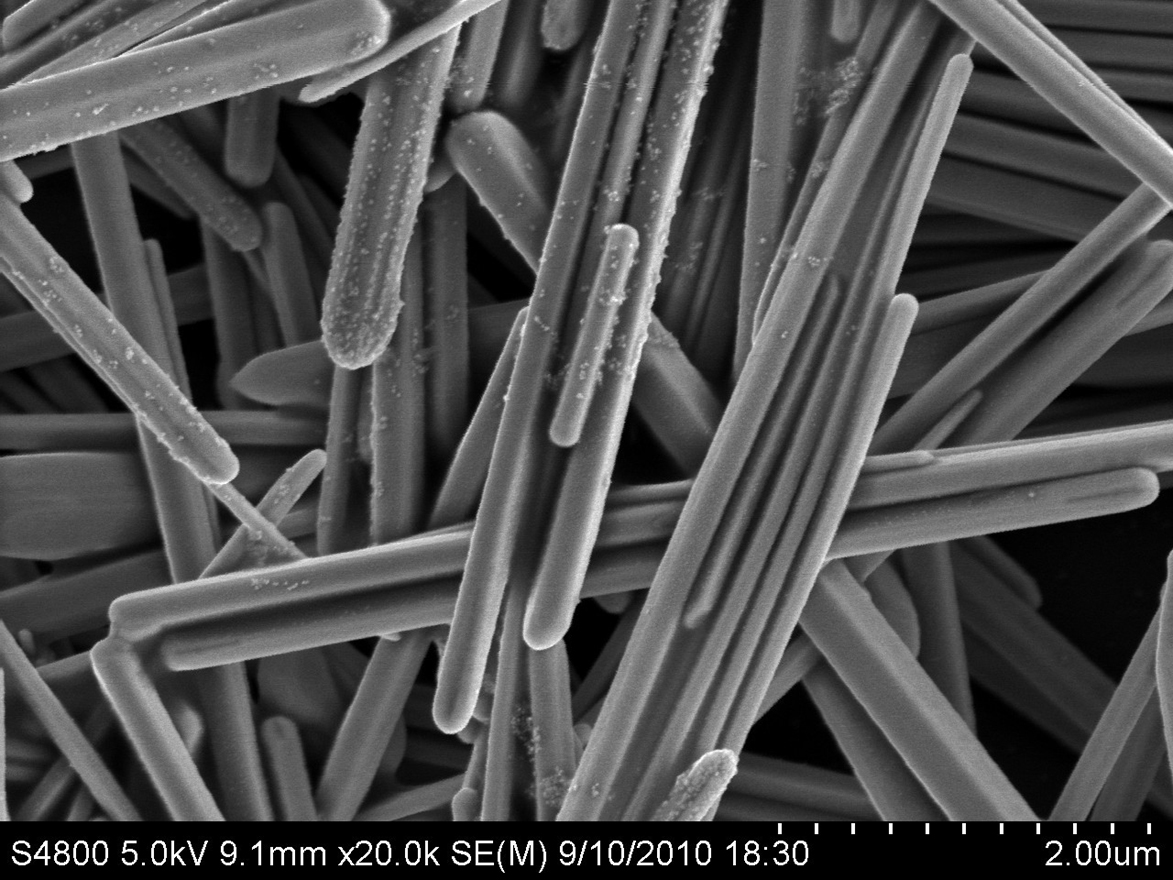

[0044] Mix 20g of silver acetate and 60g of PVP into a beaker filled with 400g of ethylene glycol according to a mass ratio of 1:3, and stir ultrasonically to obtain a uniform and transparent solution; prepare a solution reaction system containing silver ions; add to the solution containing silver ions Add 60 mg of sodium chloride to the reaction system, stir evenly to obtain a reaction precursor; put the prepared suspension into a microwave oven, and the reaction conditions are: 400W, 18min. Add water to the reacted solution, centrifuge at 3000 rpm for 10 minutes to obtain a precipitate, then wash with deionized water, absolute ethanol or acetone three to four times, and dry at regular temperature to obtain solid silver nanowire powder. The scanning electron microscope test sample is to stick the sample on the aluminum base sample stage, figure 2 The silver nanowire SEM photo that obtains according to embodiment 2 is provided; The wire diameter of this nanowire is 280nm, and...

Embodiment 3

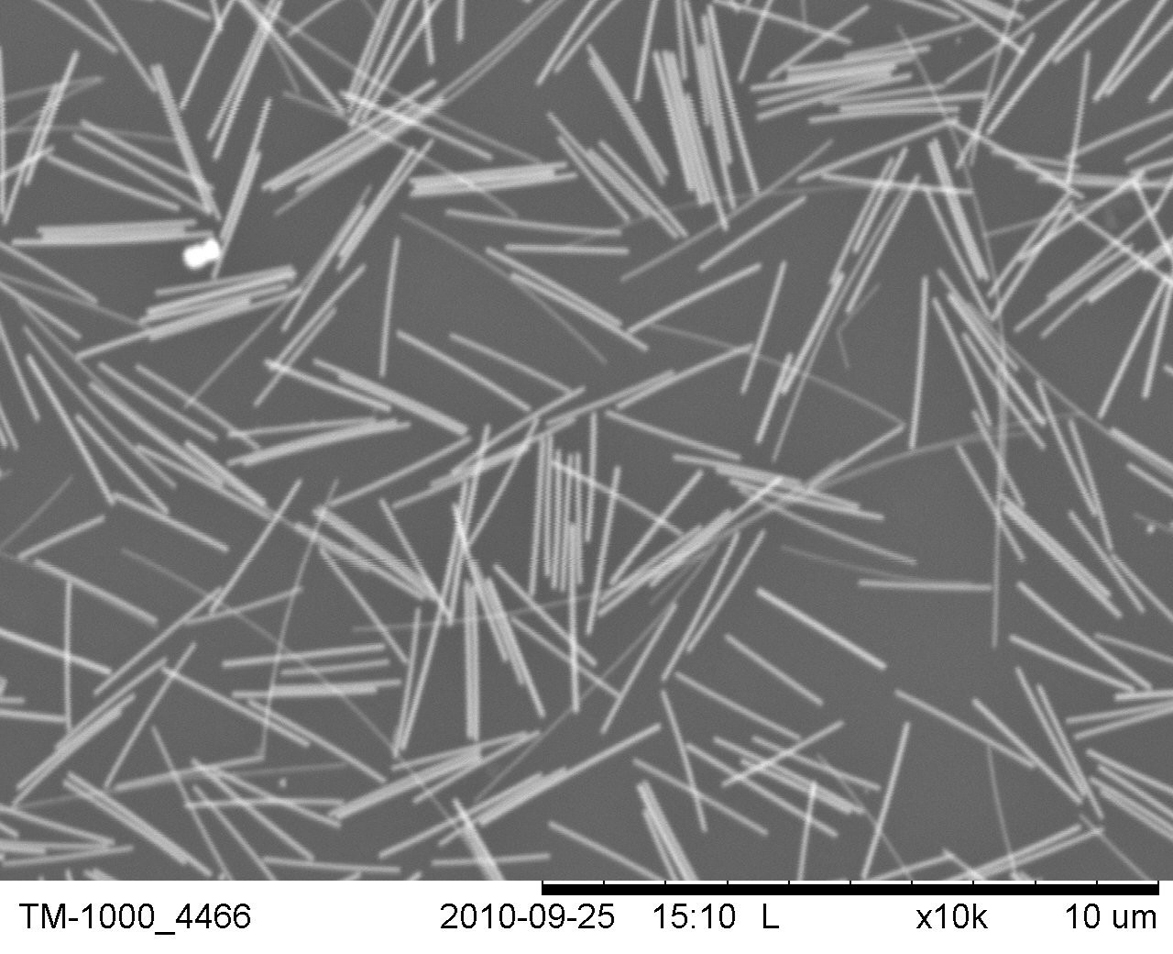

[0050] Mix 15g of silver nitrate and 30g of PVP into a beaker filled with 500g of ethylene glycol according to a mass ratio of 1:1, and stir ultrasonically to obtain a uniform and transparent solution; prepare a solution reaction system containing silver ions; add to the solution containing silver ions Add 100 mg of sodium chloride to the reaction system, stir evenly to obtain a reaction precursor; put the prepared suspension into a microwave oven, and the reaction conditions are: 480W, 16min. Add water to the reacted solution, centrifuge at 2000 rpm for 20 minutes to obtain a precipitate, then wash with deionized water, absolute ethanol or acetone three to four times, and dry at regular temperature to obtain solid silver nanowire powder. The scanning electron microscope test sample is to stick the sample on the aluminum base sample stage, image 3 The SEM photo of the silver nanowire obtained according to Example 3 is given, the wire diameter of the nanowire is 92nm, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com