Freeze-etching agent of ultra-low-carbon steel casting billet macrograph grain structure, and preparation method thereof

A technology of ultra-low carbon steel and cold etchant, which is applied in the field of metallurgical analysis, can solve the problems of inability to inspect the original size of ultra-low carbon steel continuous casting billet at low magnification, and cannot display it completely, etc., and achieves fast inspection speed. , less pollution, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

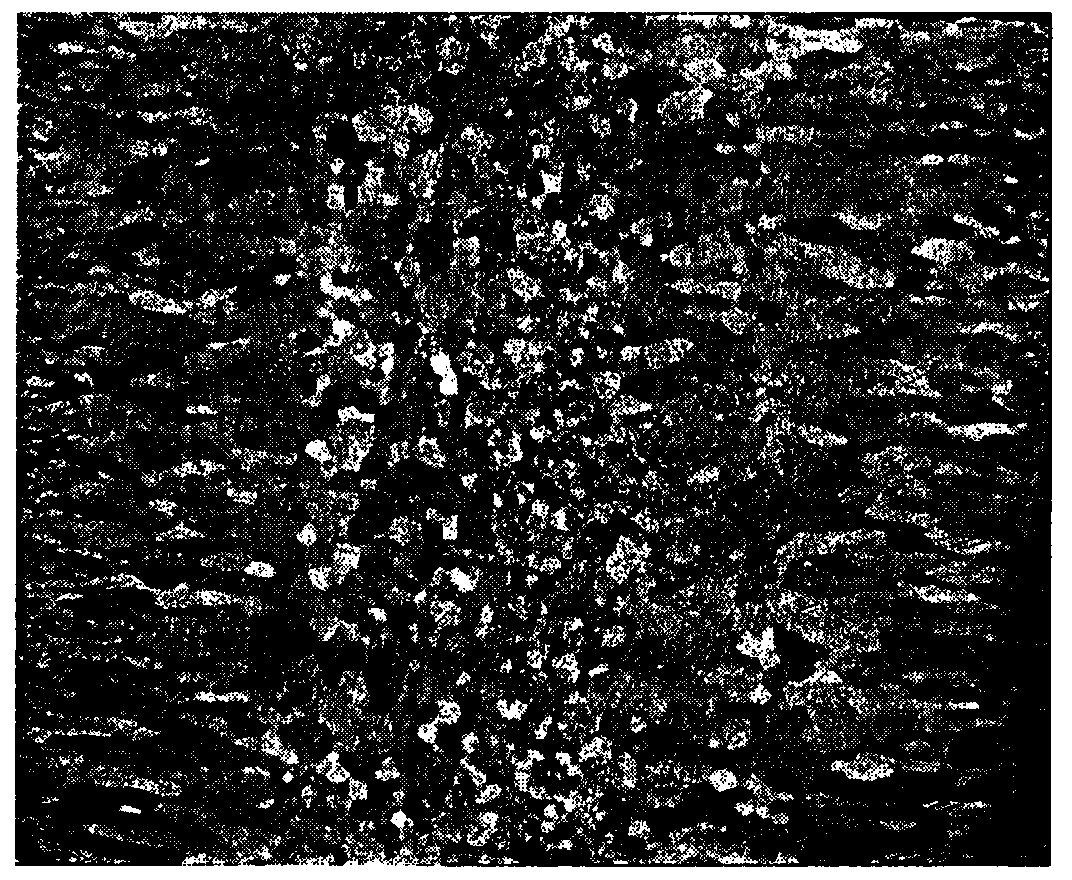

Image

Examples

Embodiment 1

[0035] It is used to display the low-magnification grain structure morphology of ultra-low carbon steel continuous casting slabs containing 0.001% to 0.004% C and a small amount of S.P.

[0036] Mix 30 grams of ferric chloride, 3 grams of picric acid, and 1.0 grams of stannous chloride in a glass container, take 1600 ml of distilled water, and divide it into two parts, one part is added to the glass container, and the other part is set aside. Stir the solid medicine until it is completely dissolved. Measure 20 milliliters of sodium alkylbenzene sulfonate and pour it into a glass container and continue to stir evenly. Take 300 milliliters of absolute ethanol and add it to spare distilled water. Take 600 ml of hydrochloric acid and add it to the aqueous ethanol solution. After stopping for 2-5 minutes, pour ethanol+hydrochloric acid aqueous solution into the aqueous solution containing ferric chloride agent to form comprehensive medicinal solution I.

[0037] Wipe the surface ...

Embodiment 2

[0039] It is used to display the low-magnification microstructure of ultra-low carbon steel continuous casting slabs with a C content of 0.004% to 0.009%, a low S and P content, and trace alloy elements V, Ti, and Ni.

[0040] Mix 40 grams of ferric chloride, 2 grams of picric acid, and 0.8 grams of stannous chloride in a glass container, take 1800 ml of distilled water, and divide it into two parts, one part is added to the glass container, and the other part is used for later use. Stir the solid medicine until it is completely dissolved. Measure 10 milliliters of sodium alkylbenzene sulfonate and pour it into a glass container and continue to stir evenly. Take 400 milliliters of absolute ethanol and add it to spare distilled water. Take 800 ml of hydrochloric acid and add it to the ethanol aqueous solution. After stopping for 2-5 minutes, pour ethanol+hydrochloric acid aqueous solution into the aqueous solution containing ferric chloride to form comprehensive medicinal solu...

Embodiment 3

[0043] It is used to display the low-magnification grain structure morphology of ultra-low carbon steel continuous casting slabs with a C content of 0.009% to 0.03%, a low S.P content, and a small amount of V, Ti, Ni, Cr and other alloying elements.

[0044]Mix 50 grams of ferric chloride, 2 grams of picric acid, and 0.6 grams of stannous chloride in a glass container, take 2000 ml of distilled water, and divide it into two parts, one part is added to the glass container, and the other part is used for later use. Stir the solid medicine until it is completely dissolved. Measure 10 milliliters of sodium alkylbenzene sulfonate and pour it into a glass container and continue to stir evenly. Take 500 milliliters of absolute ethanol and add it to spare distilled water. Take 1000 ml of hydrochloric acid and add it to the aqueous ethanol solution. After stopping for 2-5 minutes, pour ethanol+hydrochloric acid aqueous solution into the aqueous solution containing ferric chloride to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com