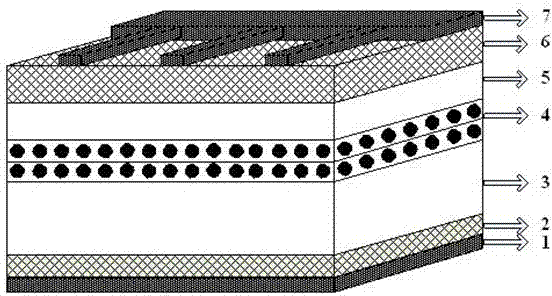

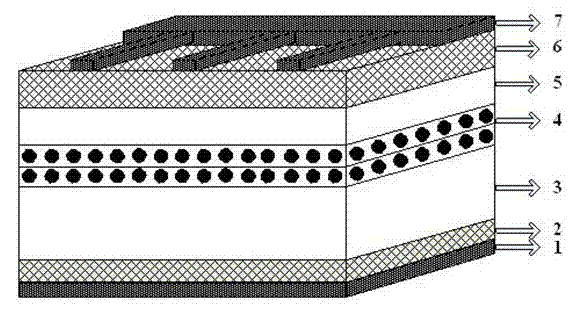

N-i-p heterojunction solar cell with silicon quantum dot and preparation method thereof

A solar cell and n-i-p technology, applied in the field of nanomaterials and solar cells, can solve problems such as the hazards of the earth's environment and threats to human living space, and achieve the effects of strengthening photogenerated current, reducing material costs, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

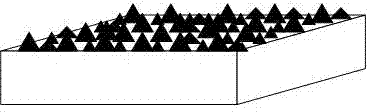

[0044] (1) Clean the N-type monocrystalline silicon substrate;

[0045] (2) Prepare the pyramid textured structure on the N-type single crystal silicon substrate, and the chemical solvent used for the texture is the prepared solution of potassium hydroxide, deionized water and isopropanol. Wherein, the volumes of deionized water and isopropanol required per gram of potassium hydroxide are: 0.35ml and 1.86ml respectively. The N-type monocrystalline silicon substrate is placed in the prepared chemical solvent and kept in a constant temperature water bath at 75°C for 45 minutes, and the average height of the pyramids formed is between 3 and 8um, and the N-type monocrystalline silicon substrate 3 is obtained;

[0046] (3) Perform NH on the monocrystalline silicon substrate 3 that has been finished with pyramid texture 3 Plasma treatment for 8 minutes, in which NH 3 The flow rate is 45sccm, the RF power is 40W, the substrate temperature is 200°C, and the pressure is 60Pa;

[004...

Embodiment 2

[0054] (1) Clean the N-type monocrystalline silicon substrate;

[0055] (2) Prepare the pyramid textured structure on the N-type single crystal silicon substrate, and the chemical solvent used for the texture is the prepared solution of potassium hydroxide, deionized water and isopropanol. Wherein, the volumes of deionized water and isopropanol required per gram of potassium hydroxide are: 0.35ml and 1.86ml respectively. The N-type monocrystalline silicon substrate is placed in the prepared chemical solvent and kept in a constant temperature water bath at 75°C for 45 minutes, and the average height of the pyramids formed is between 3 and 8um, and the N-type monocrystalline silicon substrate 3 is obtained;

[0056] (3) Perform NH on the monocrystalline silicon substrate 3 that has been finished with pyramid texture 3 Plasma treatment for 8 minutes, in which NH 3 The flow rate is 55sccm, the RF power is 60W, the substrate temperature is 220°C, and the pressure is 60Pa;

[005...

Embodiment 3

[0064] (1) Clean the N-type monocrystalline silicon substrate;

[0065] (2) Prepare the pyramid textured structure on the N-type single crystal silicon substrate, and the chemical solvent used for the texture is the prepared solution of potassium hydroxide, deionized water and isopropanol. Wherein, the volumes of deionized water and isopropanol required per gram of potassium hydroxide are: 0.35ml and 1.86ml respectively. The N-type monocrystalline silicon substrate is placed in the prepared chemical solvent and kept in a constant temperature water bath at 75°C for 45 minutes, and the average height of the pyramids formed is between 3 and 8um, and the N-type monocrystalline silicon substrate 3 is obtained;

[0066] (3) Perform NH on the monocrystalline silicon substrate 3 that has been finished with pyramid texture 3 Plasma treatment for 8 minutes, in which NH 3 The flow rate is 65sccm, the RF power is 40W, the substrate temperature is 220°C, and the pressure is 70Pa;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com