Method for preparing nano-titanium dioxide with controllable phase composition

A nano-titanium dioxide and butyl titanate technology, applied in the field of chemistry, can solve the problems of difficult particle size control, waste of resources, etc., and achieve the effects of small grain size, controllable grain size, and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

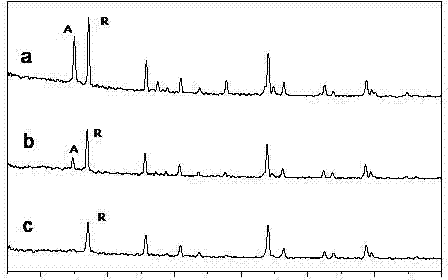

[0029] as attached figure 1 As shown in the curve a, the preparation method of nano-titanium dioxide with controllable crystal phase composition of the present invention includes the following steps: adding 1.2 g of cetyltrimethylammonium bromide (CTAB) to 100 g of absolute ethanol- Cyclohexane mixture, in which the ratio of absolute ethanol to cyclohexane is 4.2:1, stir until cetyltrimethylammonium bromide (CTAB) is completely dissolved; add 14.3g n-octanol and 3.2g pH to the liquid Nitric acid aqueous solution with pH=6, after stirring evenly, add 6.7g of butyl titanate, stir for 0.5 hours, let stand for 6 days, dry at 100°C to constant weight, and bake at 650°C for 5 hours. The rutile phase in the prepared nano-titanium dioxide is 62.9%, and the anatase phase is 37.1%.

Embodiment 2

[0031] as attached figure 1 As shown in the middle b curve, the preparation method of nano-titanium dioxide with controllable crystal phase composition of the present invention comprises the following steps: adding 1.2 g of cetyltrimethylammonium bromide to 100 g of dehydrated alcohol-cyclohexyl alkane mixture, wherein the mass ratio of absolute ethanol to cyclohexane is 2.1:1, and stirred until cetyltrimethylammonium bromide (CTAB) is completely dissolved. Add 14.3g of n-octanol and 3.2g of nitric acid aqueous solution with pH=6 to the liquid, stir evenly, add 6.7g of butyl titanate, stir for 0.5 hour, and let it stand for 6 days. Dry at 100°C to constant weight. Baking at 650°C for 5 hours. The rutile phase in the prepared nano-titanium dioxide is 80.5%, and the anatase phase is 19.5%.

Embodiment 3

[0033] as attached figure 1 As shown in the curve c in the middle, the preparation method of nano-titanium dioxide with controllable crystal phase composition of the present invention comprises the following steps: adding 1.2 g of cetyltrimethylammonium bromide (CTAB) to 100 g of absolute ethanol -Cyclohexane mixed solution, wherein the absolute ethanol-cyclohexane mass ratio is 1:1, stirred until cetyltrimethylammonium bromide (CTAB) is completely dissolved. Add 14.3g of n-octanol and 3.2g of nitric acid aqueous solution with a pH of 6 to the liquid, stir evenly, add 6.7g of butyl titanate, stir for 0.5 hours, let stand for 6 days, dry at 100°C until constant weight, 650°C Lower roasting for 5 hours. The rutile phase in the prepared nano-titanium dioxide is 100%, and the anatase phase is 0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com