Preparation method of nitrogen-doped silicon-aluminum immobilized TiO2 porous ceramic

A technology of porous ceramics and nitrogen doping, applied in the field of photocatalytic materials, can solve the problems of high cost, complex gas phase method equipment, and high energy consumption, and achieve the effect of effective doping, increasing photocatalytic activity, and increasing porous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Weigh a certain amount of Na according to the molar ratio of Si / Ti / Al / CTAB of 1:2:0.1:0.25 2 SiO 3 , Ti(SO 4 ) 2 、Al 2 (SO 4 ) 3 and CTAB reagent, ground into fine powder and prepared saturated solution with deionized water respectively;

[0033] (2) The prepared Ti 2 (SO 4 ) 2 and Al 2 (SO 4 ) 3 The solutions were mixed to form solution A; then the mixed solution A was added dropwise to Na 2 SiO 3 A colloidal solution B is formed in the solution; after stirring for ten minutes, the template solution is added to the B solution, and the stirring is continued to form a white milky suspension C;

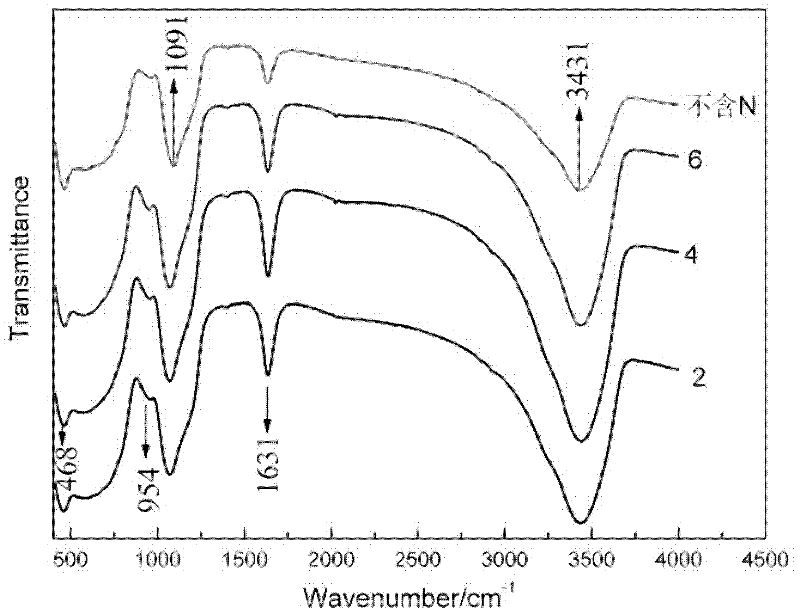

[0034] (3) Add a certain amount of urea solution with a concentration of 5mol / L to liquid C according to the ratio of N / Ti molar ratio of 4, stir while adjusting the pH value to 4 with NaOH solution, and continue stirring for half an hour to form a suspension D ;

[0035] (4) Transfer the prepared suspension D into a hydrothermal kettle for hydrothermal reactio...

Embodiment 2

[0040] (1) Weigh a certain amount of Na according to the molar ratio of Si / Ti / Al / CTAB of 1:2:0.1:0.25 2 SiO 3 , Ti(SO 4 ) 2 、Al 2 (SO 4 ) 3 and CTAB reagent, ground into fine powder and prepared saturated solution with deionized water respectively;

[0041] (2) The prepared Ti 2 (SO 4 ) 2 and Al 2 (SO 4 ) 3 The solutions were mixed to form solution A; then the mixed solution A was added dropwise to Na 2 SiO 3 A colloidal solution B is formed in the solution; after stirring for ten minutes, the template solution is added to the B solution, and the stirring is continued to form a white milky suspension C;

[0042] (3) Add a certain amount of urea solution with a concentration of 5 mol / L to the liquid C according to the ratio of N / Ti molar ratio of 6, and adjust the pH value to 4.5 with NaOH solution while stirring, and continue to stir for half an hour to form a suspension D;

[0043] (4) Move the prepared suspension D into a hydrothermal kettle for hydrothermal re...

Embodiment 3

[0048] (1) Weigh a certain amount of Na according to the molar ratio of Si / Ti / Al / CTAB of 1:2:0.1:0.25 2 SiO 3 , Ti(SO 4 ) 2 、Al 2 (SO 4 ) 3 and CTAB reagent, ground into fine powder and prepared saturated solution with deionized water respectively;

[0049] (2) The prepared Ti 2 (SO 4 ) 2 and Al 2 (SO 4 ) 3 The solutions were mixed to form solution A; then the mixed solution A was added dropwise to Na 2 SiO 3 A colloidal solution B is formed in the solution; after stirring for ten minutes, the template solution is added to the B solution, and the stirring is continued to form a white milky suspension C;

[0050] (3) Add a certain amount of urea solution with a concentration of 5mol / L to the suspension C according to the ratio of N / Ti molar ratio of 2, stir and adjust the pH value to 3.5 with NaOH solution at the same time, and continue to stir for half an hour to form a suspension D ;

[0051] (4) Move the prepared suspension D into a hydrothermal kettle for hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com