Flexible epoxy adhesive and application

An epoxy adhesive, flexible epoxy technology, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of poor low temperature resistance, poor aging resistance, etc., and achieve excellent durability, high road comfort, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

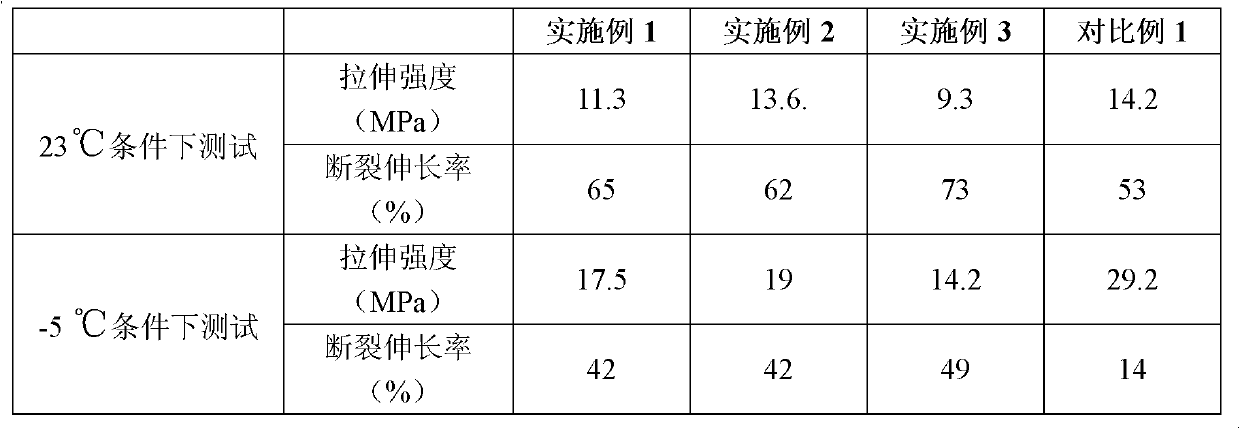

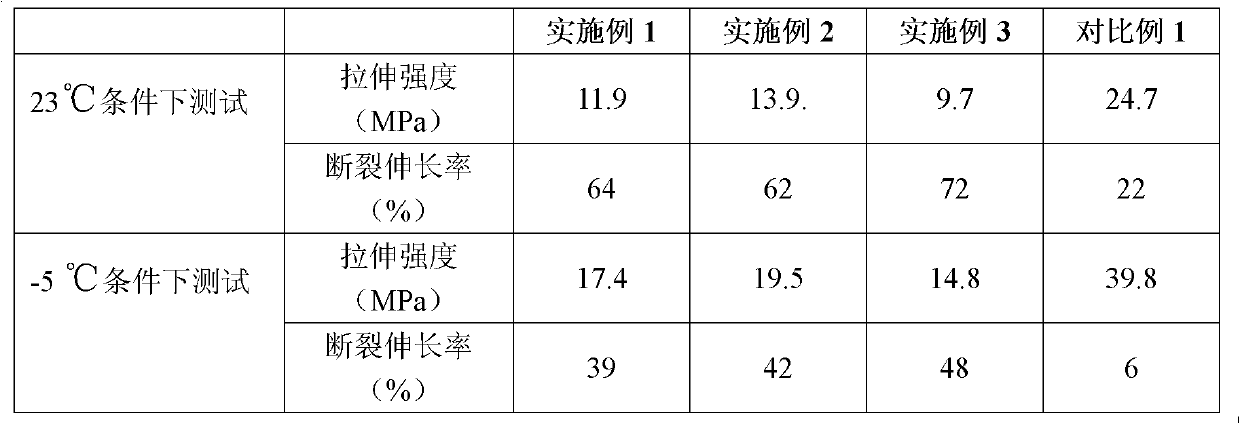

Examples

Embodiment 1

[0035] Preparation of acrylate group-terminated polyurethane: heat up 800g polyethylene glycol (PEG) to 105°C for dehydration for 1 hour, cool to room temperature, add 100g toluene diisocyanate (TDI), 100g hexamethylene diisocyanate (HDI) to heat up React at 85° C. for 2.5 hours, then add 38 grams of hydroxyethyl acrylate (HEA) to continue the reaction, and monitor the reaction by infrared spectroscopy until the reaction is complete, thus obtaining the target product. The product viscosity is 30000mpa.s (25°C) (rotational viscometer test).

[0036] Preparation of modified curing agent: Add 400g of phenol, 500g of nonylphenol, 450g of formaldehyde, 800g of D230, and 800g of D400 into the reaction vessel, raise the temperature to 115°C for 2 hours, and then distill off small molecular substances to obtain the target product.

[0037] Component A is obtained by mixing and stirring the following components in parts by mass: E51100, acrylate group-terminated polyurethane 42, benzyl...

Embodiment 2

[0041] Preparation of acrylate group-terminated polyurethane: 500g polyethylene glycol (PEG) and 500g polypropylene glycol (PPG) were heated to 105°C for dehydration for 1h, cooled to room temperature, 70g toluene diisocyanate (TDI), 90g hexamethylene Base diisocyanate (HDI), 60g isophorone diisocyanate IPDI is warmed up to 85 ℃ and reacts for 2.5 hours, then adds 20 grams of hydroxyethyl acrylate (HEA), 25 grams of hydroxypropyl acrylate (HPA) to continue the reaction, by infrared spectroscopy The reaction is monitored until it is complete and the target product is obtained. The viscosity is 35000mpa.s (25°C) (rotational viscometer test).

[0042] Preparation of modified curing agent: Add 600g of phenol, 300g of nonylphenol, 550g of formaldehyde, 1000g of D230, and 700g of D400 into the reaction vessel, raise the temperature to 115°C for 2 hours, and then distill off small molecular substances to obtain the target product.

[0043] Component A is obtained by mixing and stirr...

Embodiment 3

[0047]Preparation of acrylate group-terminated polyurethane: 300g of polyethylene glycol PEG, 700g of polypropylene glycol PPG, and 200g of polytetrahydrofuran glycol PTMEG were heated to 100°C for dehydration for 1 hour, cooled to room temperature, and 100g of diphenylmethane diisocyanate MDI, 80g xylylene diisocyanate XDI, 50g hexamethylene diisocyanate (HDI) heated to 85 ℃ for 2.5 hours, then added 15g hydroxyethyl acrylate HEA, 20g hydroxypropyl acrylate HPA, 15g hydroxybutyl acrylate HBA The reaction was continued, and the reaction was monitored by infrared spectroscopy until the reaction was complete, so that the target product was obtained. The viscosity is 37000mpa.s (25°C) (rotational viscometer test).

[0048] Preparation of modified curing agent: Add 300g of phenol, 700g of nonylphenol, 450g of formaldehyde, 600g of D230, and 1200g of D400 into the reaction vessel, raise the temperature to 115°C for 2 hours, and then distill off small molecular substances to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com