Environment-friendly papermaking coating using biological latex

A bio-latex, environmentally friendly technology, applied in paper coating, papermaking, textiles and papermaking, etc., can solve the problems of soaring production cost of coated paper, restrict the development of coated paper, hinder the development of coated paper, etc., and achieve improved formula and Effects of craftsmanship, expansion of uses, and improvement of paper quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

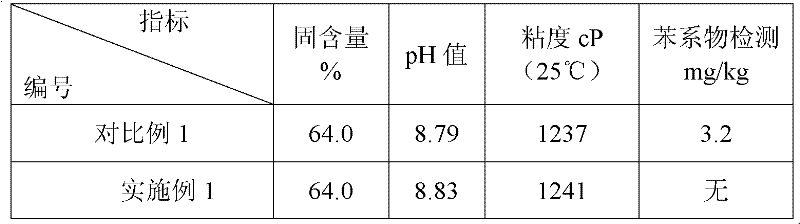

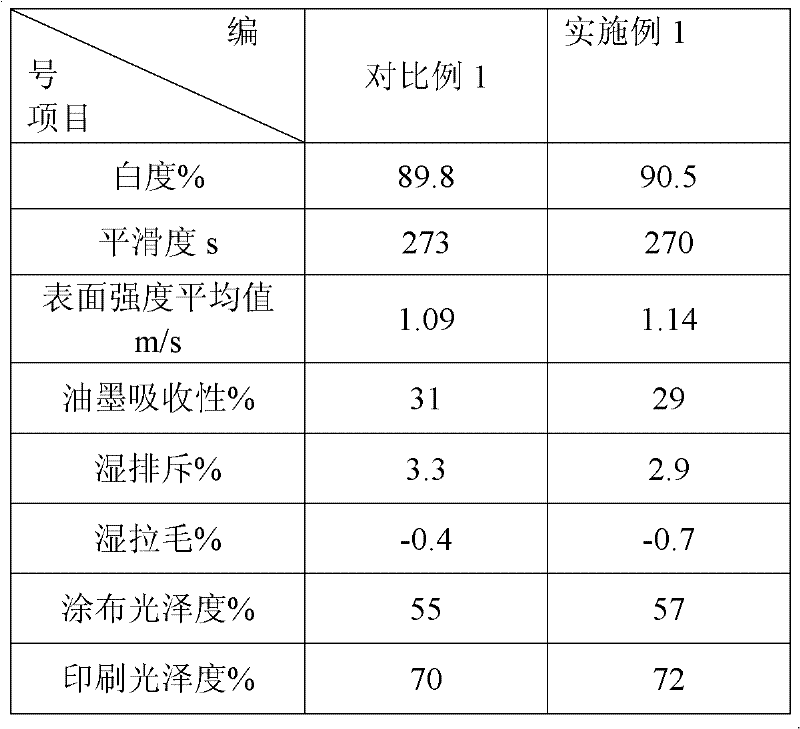

Examples

Embodiment 1

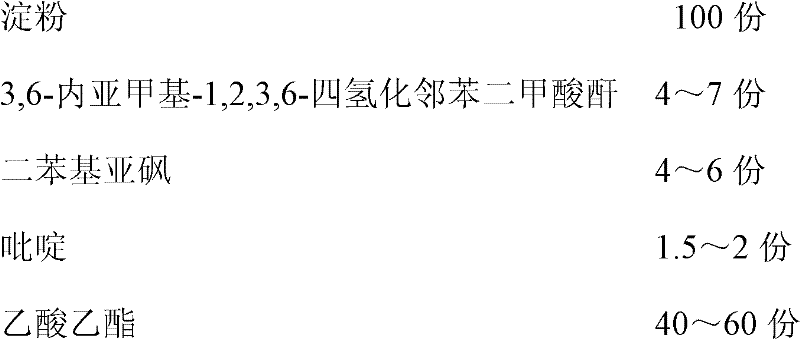

[0032] formula:

[0033] 10% biological latex, 80% heavy calcium, 5% dispersant, 0.2% lubricant, 3% anti-water agent, 1.8% thickener.

[0034] The heavy calcium adopts the product of model GX-GCC D55 produced by Shanghai Dongsheng New Material Co., Ltd.;

[0035] The dispersant is a polyacrylic acid dispersant, and the model DS-FS 142 produced by Shanghai Dongsheng New Material Co., Ltd. is used;

[0036] The lubricant is a high-grade fatty acid salt, and the product model DS-RH 316 produced by Shanghai Dongsheng New Material Co., Ltd. is used;

[0037] The water repellant is with C-NH 2 The aqueous solution of the polyamide polyurea glycidyl ester of the group adopts the product of the model DS-KS 601 produced by Shanghai Dongsheng New Material Co., Ltd.;

[0038] The thickener adopts sodium carboxymethyl cellulose.

[0039] The preparation method of biological latex:

[0040] Mix 50 grams of starch, 3.5 grams of 3,6-endomethylene-1,2,3,6-tetrahydrophthalic anhydride, 2 ...

Embodiment 2

[0054] 20% of biological latex, 70% of heavy calcium, 3% of dispersant, 5% of lubricant, 0.5% of anti-water agent, 0.2% of thickener, and 0.3% of antibacterial agent.

[0055] Heavy calcium, dispersant, lubricant and anti-water agent are the same as embodiment 1, and bacteriostatic agent adopts potassium sorbate. The preparation method of biological latex:

[0056] Mix 50 grams of starch, 2 grams of 3,6-endomethylene-1,2,3,6-tetrahydrophthalic anhydride, 3 grams of diphenyl sulfoxide, and 1 gram of pyridine for 10 hours, pour into 30 gram of ethyl acetate, filtered to obtain a white paste, and processed by reactive extrusion to obtain nano-scale modified starch with a particle diameter of 120nm. The reactive extrusion processing adopts the method disclosed in CN101535397A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com