Composite film substrate and composite film using same

A technology for composite membranes and supports, applied in the field of composite membranes and methods, separation membranes and separation membrane elements using the composite membrane support, can solve the problems of uneven area weight, inhomogeneity, unevenness, etc., and achieve High thermal adhesion, high adhesiveness, low crystallinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

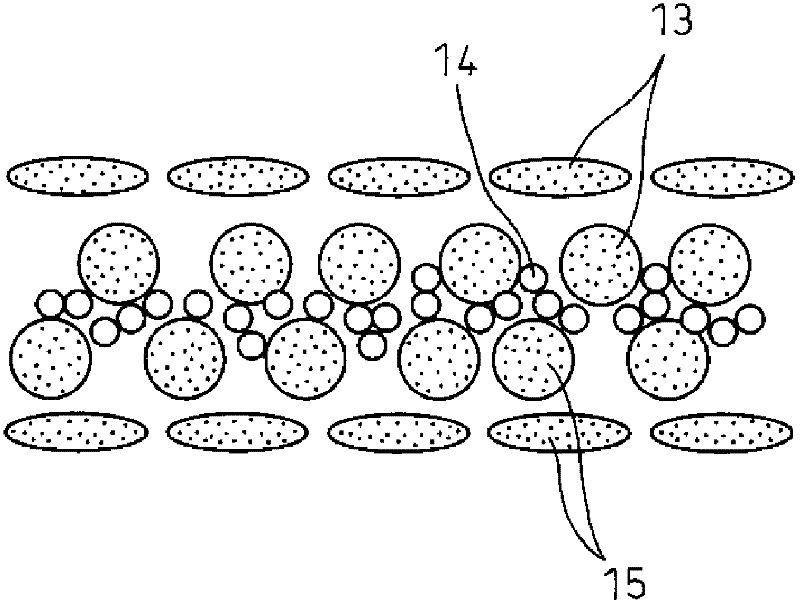

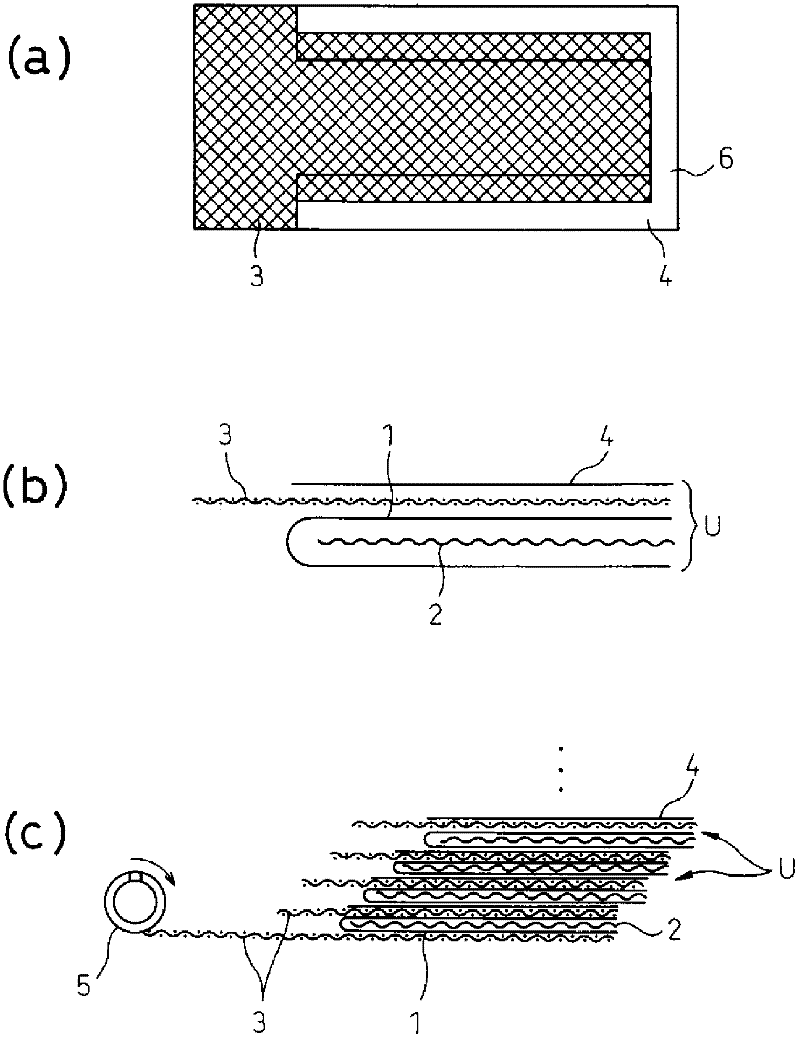

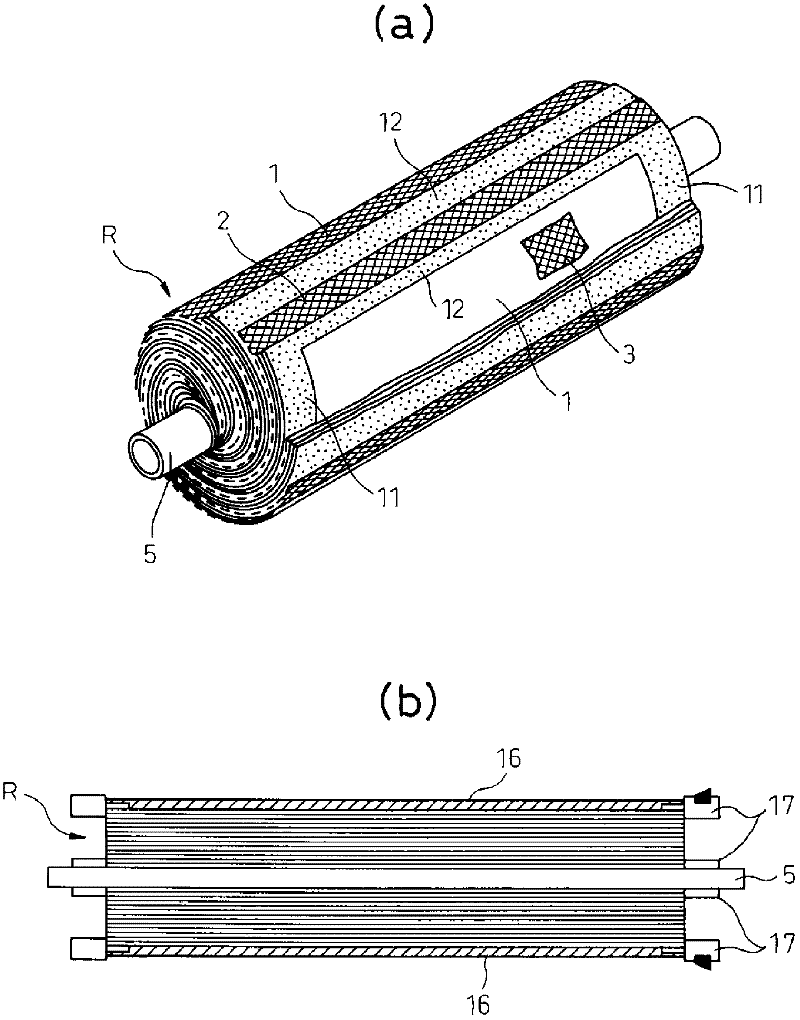

[0165] (Manufacture of Composite Membrane Support)

[0166] As the surface layer (coated surface of the composite membrane solution), polyethylene terephthalate was used as the thermoplastic resin and the filament group was extruded toward the moving wire surface at a spinning temperature of 300° C. by the spunbonding method to spun Spinning at a speed of 4000m / min, a fiber with a diameter of 11μm and a weight per unit area of 31.3g / m was produced on the catch net 2 thermoplastic long fiber web. Next, using polyethylene terephthalate as the intermediate layer, the spinning temperature was 300°C and the heating air was 1000Nm by the melt-blowing method. 3 Spinning under the condition of / hr / m, the average fiber diameter is 1.6μm, and the weight per unit area is 7.4g / m 2 A layer of meltblown fibers was blown onto the spunbond-based thermoplastic long fiber web described above. Further, by the same method as the original thermoplastic long fiber web, the fiber diameter of 12...

Embodiment 2

[0178] Set the diameter of the melt-blown fiber to 1.7 μm and the weight per unit area to 8.2 g / m 2 , set the spunbond unit area weight of the surface and inner layers to 31g / m 2 , except that, a composite membrane support was produced by the same method as in Example 1. A polyamide composite reverse osmosis membrane and a spiral composite reverse osmosis membrane element were fabricated using the obtained composite membrane support and using the same method as in Example 1.

[0179] The properties of the obtained composite membrane support body, polyamide composite reverse osmosis membrane, and spiral composite reverse osmosis membrane element are shown in Table 1 and Table 2 together.

Embodiment 3

[0181] A composite membrane support was produced by the same method as in Example 1 except that the diameter of the melt blown fiber was 1.5 μm. A polyamide composite reverse osmosis membrane and a spiral composite reverse osmosis membrane element were fabricated using the obtained composite membrane support and using the same method as in Example 1.

[0182] The properties of the obtained composite membrane support body, polyamide composite reverse osmosis membrane, and spiral composite reverse osmosis membrane element are shown in Table 1 and Table 2 together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com