Composite membrane support and composite membrane using same

A composite membrane and support technology, applied in membrane technology, semi-permeable membrane separation, textile, etc., can solve the problems of unevenness, uneven area weight, unevenness, etc., and achieve high adhesion and high thermal adhesion , The effect of low crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0165] (Manufacture of Composite Membrane Support)

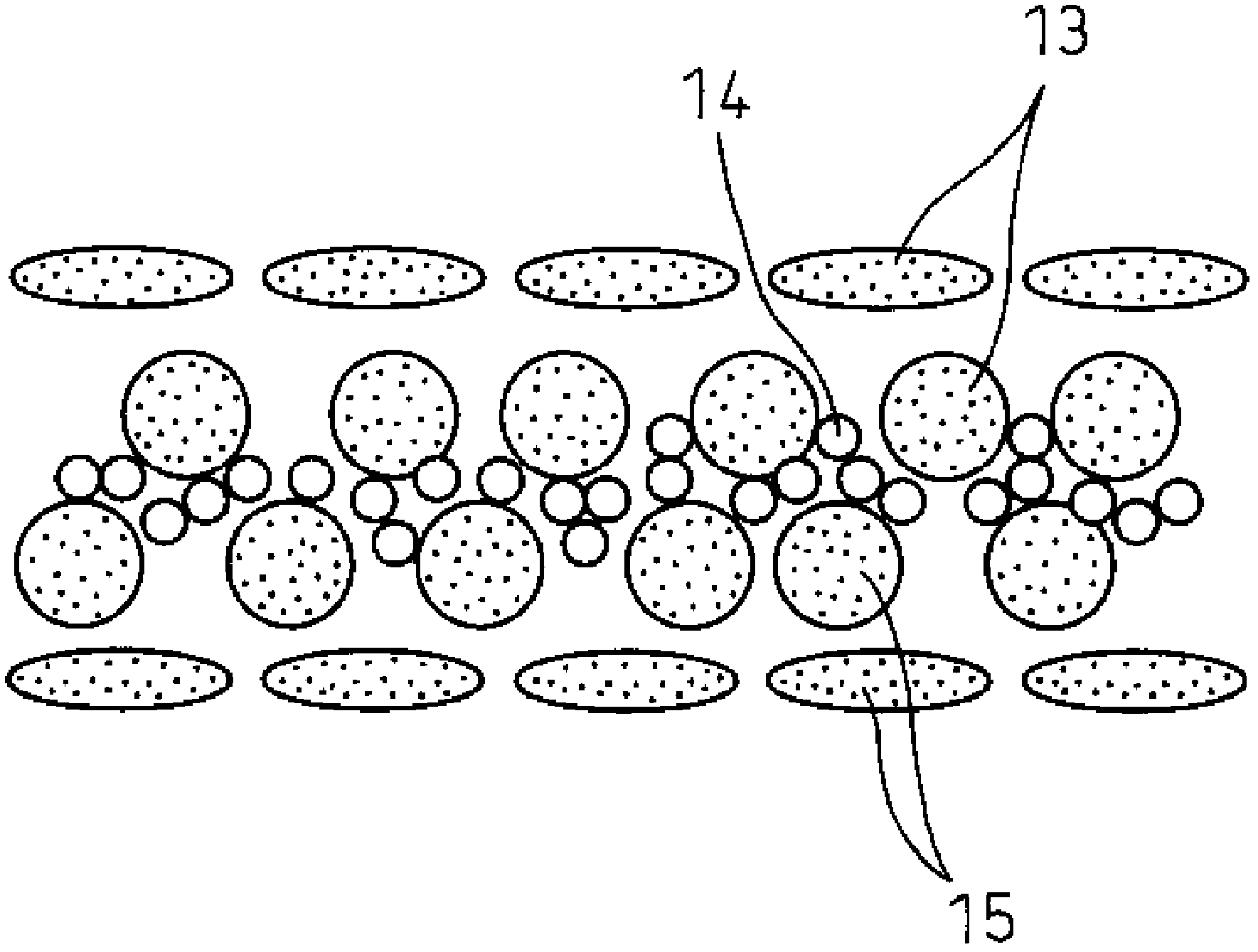

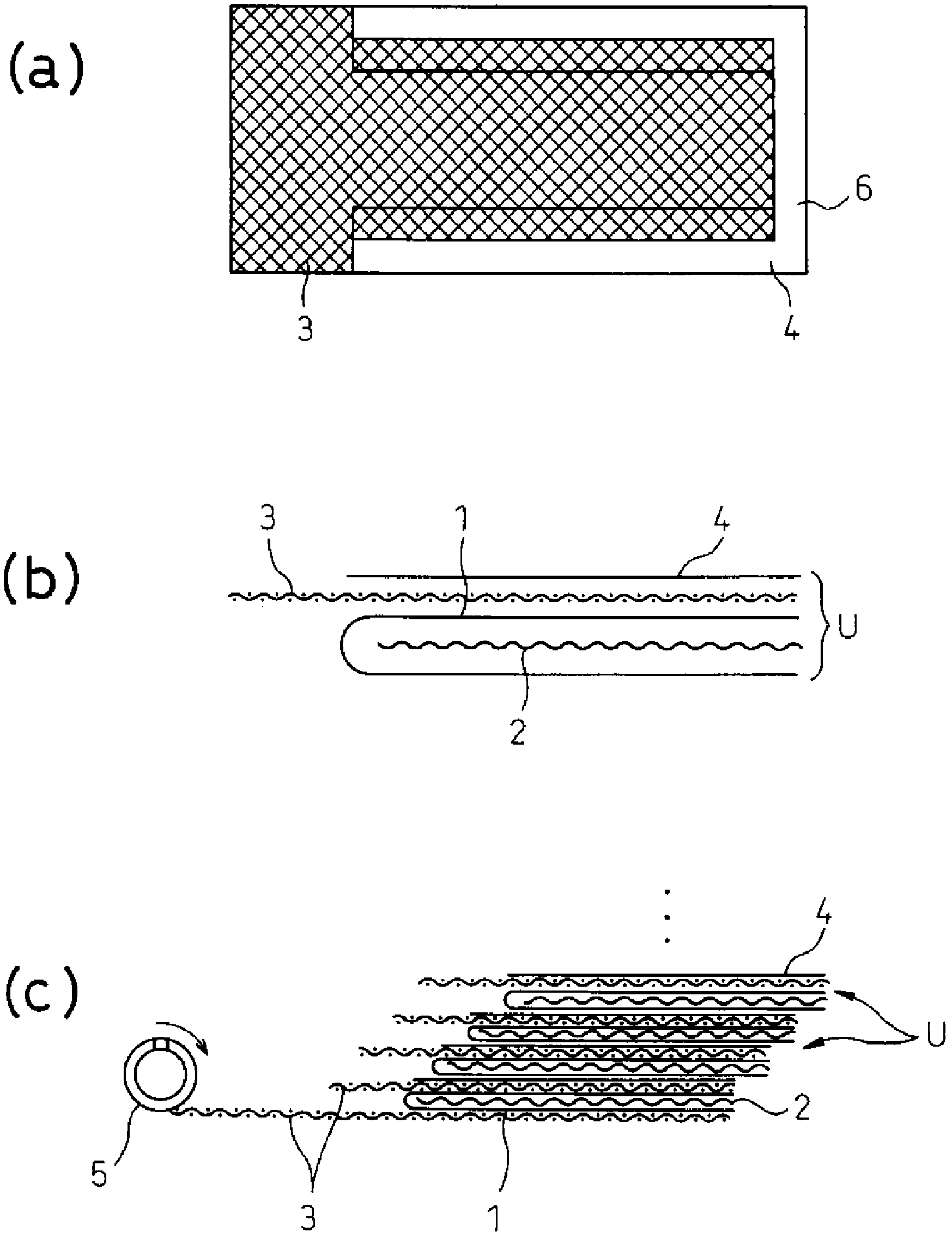

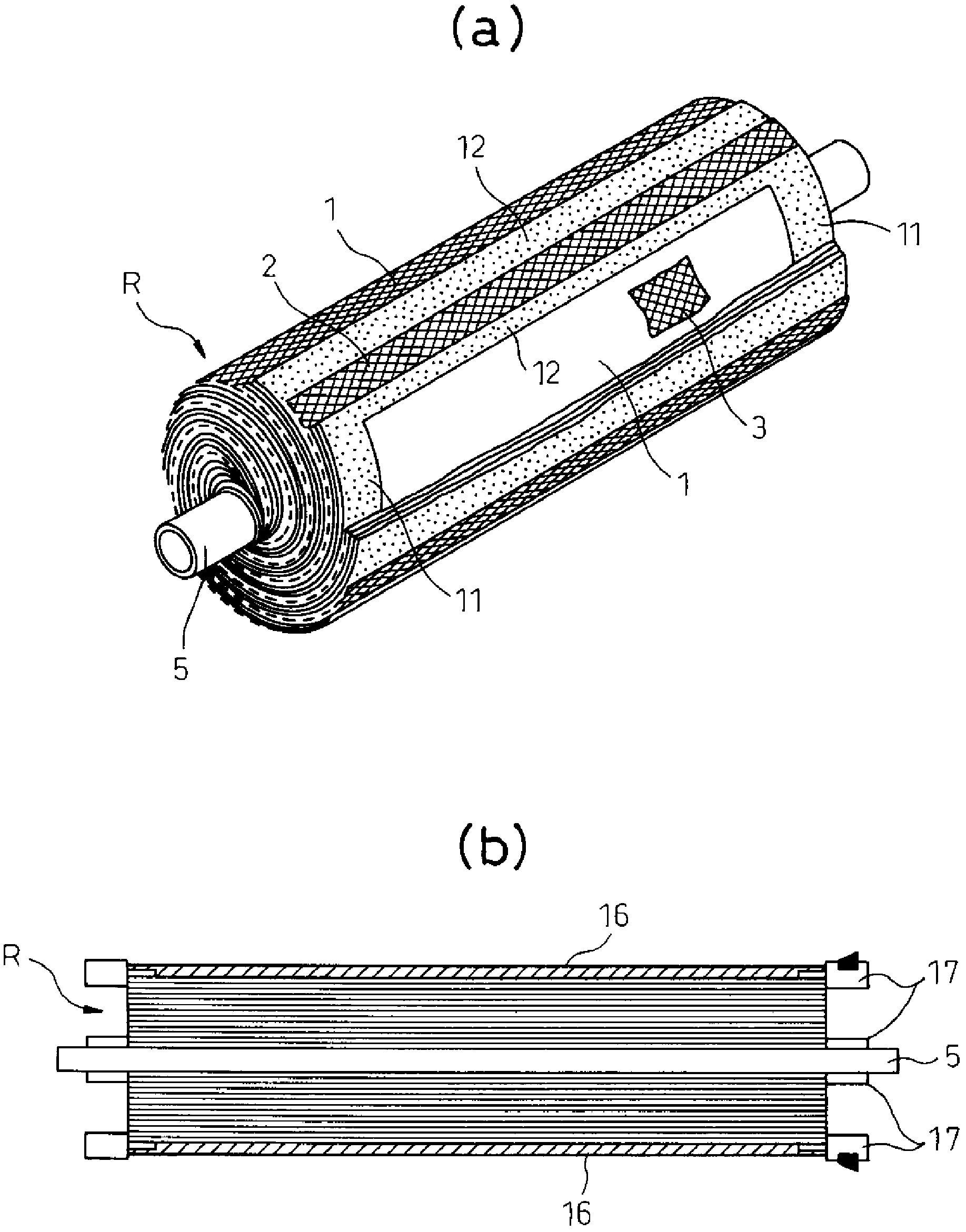

[0166] As the surface layer (coated surface of the composite membrane solution), polyethylene terephthalate was used as the thermoplastic resin and the filament group was extruded toward the moving wire surface at a spinning temperature of 300° C. by the spunbonding method to spun Spinning at a speed of 4000m / min, a fiber with a diameter of 11μm and a weight per unit area of 31.3g / m was produced on the catch net 2 thermoplastic long fiber web. Next, using polyethylene terephthalate as the intermediate layer, the spinning temperature was 300°C and the heating air was 1000Nm by the melt-blowing method. 3 Spinning under the condition of / hr / m, the average fiber diameter is 1.6μm, and the weight per unit area is 7.4g / m 2 A layer of meltblown fibers was blown onto the spunbond-based thermoplastic long fiber web described above. Further, by the same method as the original thermoplastic long fiber web, the fiber diameter of 12...

Embodiment 2

[0178] Set the diameter of the melt-blown fiber to 1.7 μm and the weight per unit area to 8.2 g / m 2 , set the spunbond unit area weight of the surface and inner layers to 31g / m 2 , except that, a composite membrane support was produced by the same method as in Example 1. A polyamide composite reverse osmosis membrane and a spiral composite reverse osmosis membrane element were fabricated using the obtained composite membrane support and using the same method as in Example 1.

[0179] The properties of the obtained composite membrane support body, polyamide composite reverse osmosis membrane, and spiral composite reverse osmosis membrane element are shown in Table 1 and Table 2 together.

Embodiment 3

[0181] A composite membrane support was produced by the same method as in Example 1 except that the diameter of the melt blown fiber was 1.5 μm. A polyamide composite reverse osmosis membrane and a spiral composite reverse osmosis membrane element were fabricated using the obtained composite membrane support and using the same method as in Example 1.

[0182] The properties of the obtained composite membrane support body, polyamide composite reverse osmosis membrane, and spiral composite reverse osmosis membrane element are shown in Table 1 and Table 2 together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com