Preparation method of ultrahigh molecular weight polyethylene

A technology of ultra-high molecular weight and polyethylene, applied in the chemical field, can solve problems such as difficult operation, and achieve the effects of simple operation, mild experimental conditions, and strong industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A 5L tank reactor is used, and the polymerization tank that has been dewatered and deoxygenated is filled with N 2 After purging for at least 3 times, inject 1.5L of hexane dried with molecular sieves and blown with nitrogen, add a certain amount of triethylaluminum and 20 mg of BCS01 catalyst, and 600 ml of hexene after deoxidation, dehydration, and purification, and tetrahydrofuran (THF), control THF / Ti=0.3 (molar ratio), and finally add 1.0L of hexane to flush the catalyst pipeline, then raise the temperature of the reactor, and add a sufficient amount of chain transfer agent H at one time when the temperature rises to 58°C 2 , control H 2 / C 2 h 4 =0.05 (molar ratio), then continuously add ethylene, the ethylene partial pressure is 1.0MPa, carry out constant pressure for 1 hour, the experimental results obtained are shown in Table 1.

Embodiment 2

[0033] The control hexene addition is 100ml, THF / Ti=1.8 (molar ratio), other experimental procedure is the same as embodiment 1, the experimental result that obtains is shown in Table 1.

Embodiment 3

[0035] The control hexene addition is 100ml, THF / Ti=1 (molar ratio), other experimental procedure is the same as embodiment 1, and the experimental result that obtains is shown in Table 1.

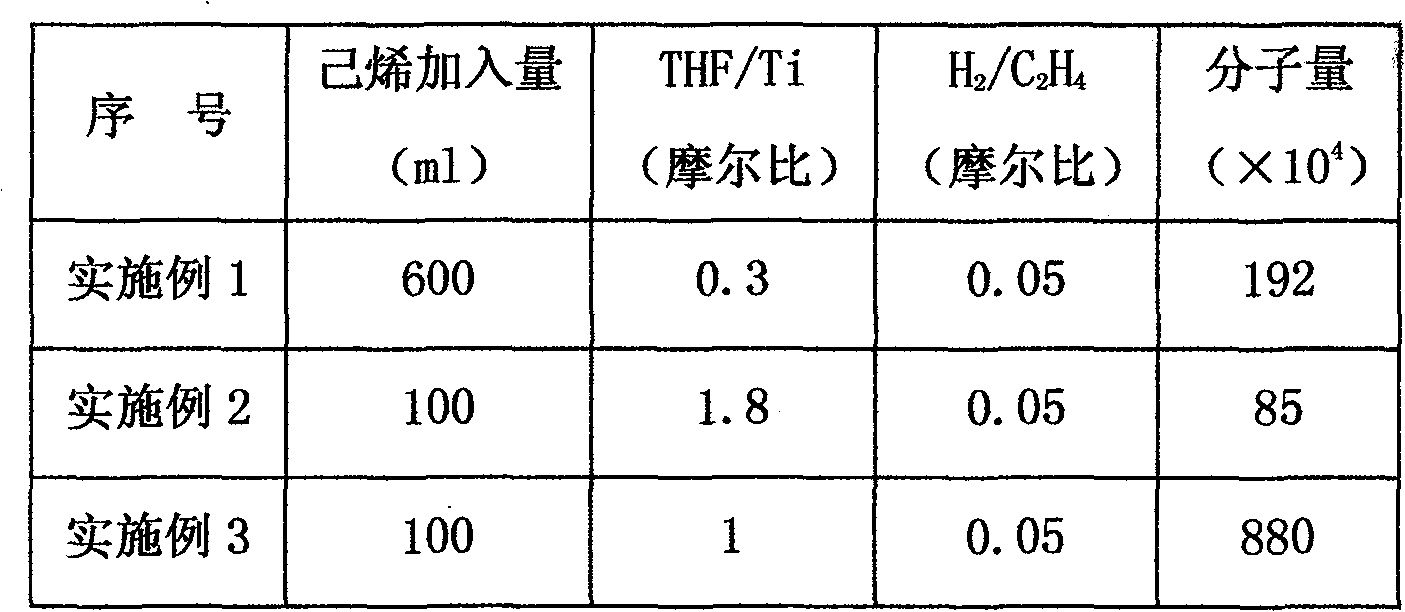

[0036] Table 1

[0037]

[0038] The test results of the above examples show that, using the BCS01 catalyst, after carrying out the copolymerization of ethylene and hexene and adding a certain amount of external electron donor, the molecular weight of the polymer has been significantly improved, and ultra-high molecular weight polyethylene is obtained. The added amount of olefin and the added amount of external electron donor can conveniently adjust the molecular weight of ultra-high molecular weight polyethylene. Under the control of hydrogen added amount, ultra-high molecular weight polyethylene with a molecular weight of more than 8 million can be obtained. The method has mild experimental conditions, simple operation and strong industrial application value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com