Preparation method of feed with chicken viscera as raw materials

A technology of chicken viscera and raw materials, applied in animal feed, animal feed, application, etc., can solve problems such as waste of resources, loss of ingredients, parasites or diseases, etc., and achieve the effects of reducing feces odor, reducing volume, and reducing feces volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

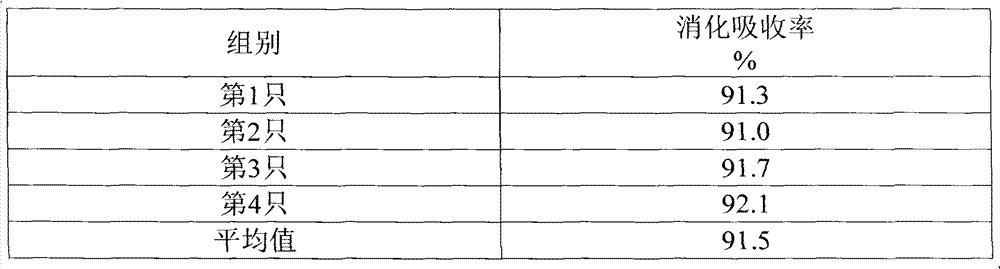

Examples

Embodiment 1

[0035] Take 10 kg of cleaned chicken viscera, add pepsin at 40°C, stir, keep warm for 3 hours, add organic solvent ethanol, mix, let stand for 2 hours, and separate the supernatant (recover the ethanol from the ethanol layer until it is exhausted, and the remaining discard), filter, and the filtrate is ultrafiltered through a molecular weight cut-off 6000 ultrafiltration membrane, and the permeate is retained, concentrated, and dried to obtain 6.43 kilograms of feed.

[0036] The above feed contains: 35.5% by weight of polypeptide and 60.84% by weight of amino acid. Aspartic Acid 1.3%, Glutamic Acid 10.4%, Threonine 2.9%, Arginine 2.4%, Proline 3.1%, Valine 0.04%, Isoleucine 3.0%, Phenylalanine 3.2% , Lysine 5.7%, Serine 3.3%, Glycine 2.6%, Histidine 1.8%, Alanine 5.7%, Cystine 1.4%, Methionine 6.8%, Leucine 5.2%, Tyrosine 2.0%.

Embodiment 2

[0038] Get 3 kilograms of cleaned chicken offal, add pepsin at 30°C, stir, keep warm for 2 hours, add organic solvent carbon tetrachloride, mix, leave standstill for 2 hours, and separate the supernatant (carbon tetrachloride layer Recover the solvent to the utmost, discard the residue), filter, and filter the filtrate through an ultrafiltration membrane with a molecular weight cut-off of 5000, retain the permeate, concentrate, and dry to obtain 188 kg of feed.

[0039] The above feed contains: 31.3% by weight of polypeptide and 58.604% by weight of amino acid. Among amino acids, aspartic acid 1.2%, glutamic acid 10.0%, threonine 2.55%, arginine 2.1%, proline 3.03%, valine 0.024%, isoleucine 2.91%, phenylalanine 3.11%, Lysine 5.63%, Serine 3.21%, Glycine 2.43%, Histidine 1.72%, Alanine 5.61%, Cystine 1.30%, Methionine 6.72%, Leucine 5.13%, Tyrosine 1.93%.

Embodiment 3

[0041] Take 1 kg of cleaned chicken viscera, add pepsin at 50°C, stir, keep warm for 5 hours, add the organic solvent petroleum ether, mix, let stand for 3 hours, and separate the supernatant (petroleum ether layer recovers petroleum ether to The residue is discarded), filtered, and the filtrate is ultrafiltered through a molecular weight cut-off 5000 ultrafiltration membrane, and the permeate is retained, concentrated, and dried to obtain 0.625 kg of feed.

[0042] The above feed contains: polypeptide weight content 34.7%, amino acid weight content 59.93%, aspartic acid 1.25%, glutamic acid 10.34%, threonine 2.91%, arginine 2.25%, proline 3.03%, valine Acid 0.03%, Isoleucine 2.96%, Phenylalanine 3.13%, Lysine 5.67%, Serine 3.28%, Glycine 2.50%, Histidine 1.73%, Alanine 5.62%, Cystine 1.40%, Methionine 6.71%, Leucine 5.15%, Tyrosine 1.97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com