Tirofiban hydrochloride lyophilization powder injection

A technology of freeze-dried powder injection and tirofiban, which is applied in the field of medicine, can solve the problems of large volume and weight, low qualified rate of foreign matter, and inconvenient transportation, and achieve the effects of stable physical and chemical properties, simple preparation process, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

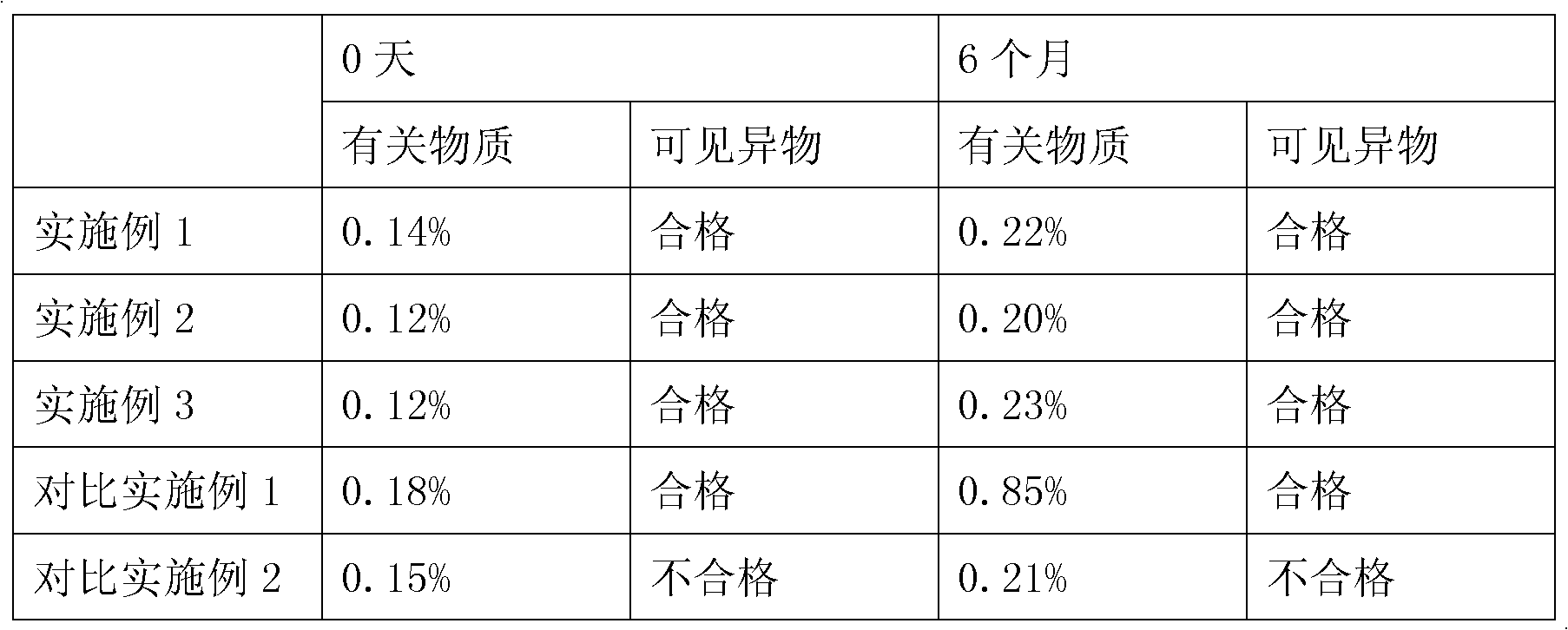

Examples

Embodiment 1

[0018] The preparation of embodiment 1 tirofiban hydrochloride freeze-dried powder preparation

[0019] Tirofiban hydrochloride (calculated as tirofiban) 1 part

[0020] Cysteine hydrochloride 0.5 part

[0021] Preparation Process:

[0022] (1) Take tirofiban hydrochloride and cysteine hydrochloride of prescription quantity, add water for injection, stir to dissolve, then the medicinal solution is sterilized by filtration through a microporous membrane of 0.22 μm, and the filtrate is poured after passing the test. Packed in vials, then half stoppered, and put into a freeze-drying box.

[0023] (2) Turn on the freeze dryer to pre-freeze the product, reduce the temperature of the product to about -40°C at 2°C / min, and keep this temperature for 8 hours. After the product is completely frozen, turn on the condenser to reduce the temperature to -45°C Below ℃, start vacuuming for freeze-drying, and then gradually increase the temperature to -5°C to basically freeze-dry the mo...

Embodiment 2

[0025] The preparation of embodiment 2 tirofiban hydrochloride freeze-dried powder preparation

[0026] Tirofiban hydrochloride (calculated as tirofiban) 1 part

[0027] Cysteine hydrochloride 2 parts

[0028] Preparation Process:

[0029] (1) Take tirofiban hydrochloride and cysteine hydrochloride of prescription quantity, add water for injection, stir to dissolve, then the medicinal solution is sterilized by filtration through a microporous membrane of 0.22 μm, and the filtrate is poured after passing the test. Packed in vials, then half stoppered, and put into a freeze-drying box.

[0030] (2) Turn on the freeze dryer to pre-freeze the product, reduce the temperature of the product to about -40°C at 2°C / min, and keep this temperature for 8 hours. After the product is completely frozen, turn on the condenser to reduce the temperature to -45°C Below ℃, start vacuuming for freeze-drying, and then gradually increase the temperature to -5°C to basically freeze-dry the moi...

Embodiment 3

[0032] The preparation of embodiment 3 tirofiban hydrochloride freeze-dried powder preparation

[0033] Tirofiban hydrochloride (calculated as tirofiban) 1 part

[0034] Cysteine hydrochloride 8 parts

[0035] Preparation Process:

[0036] (1) Take tirofiban hydrochloride and cysteine hydrochloride of prescription quantity, add water for injection, stir to dissolve, then the medicinal solution is sterilized by filtration through a microporous membrane of 0.22 μm, and the filtrate is poured after passing the test. Packed in vials, then half stoppered, and put into a freeze-drying box.

[0037] (2) Turn on the freeze dryer to pre-freeze the product, reduce the temperature of the product to about -40°C at 2°C / min, and keep this temperature for 8 hours. After the product is completely frozen, turn on the condenser to reduce the temperature to -45°C Below ℃, start vacuuming for freeze-drying, and then gradually increase the temperature to -5°C to basically freeze-dry the moi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com