Process for removing F, Cl and As from waste acid by hot air concentration method

A concentration method and technology of polluted acid, which is applied in the field of chemical technology, can solve the problems of increasing the cost of polluted acid treatment, low-quality gypsum slag, secondary pollution, etc., and achieve saving of polluted acid treatment expenses, large amount of polluted acid treatment, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

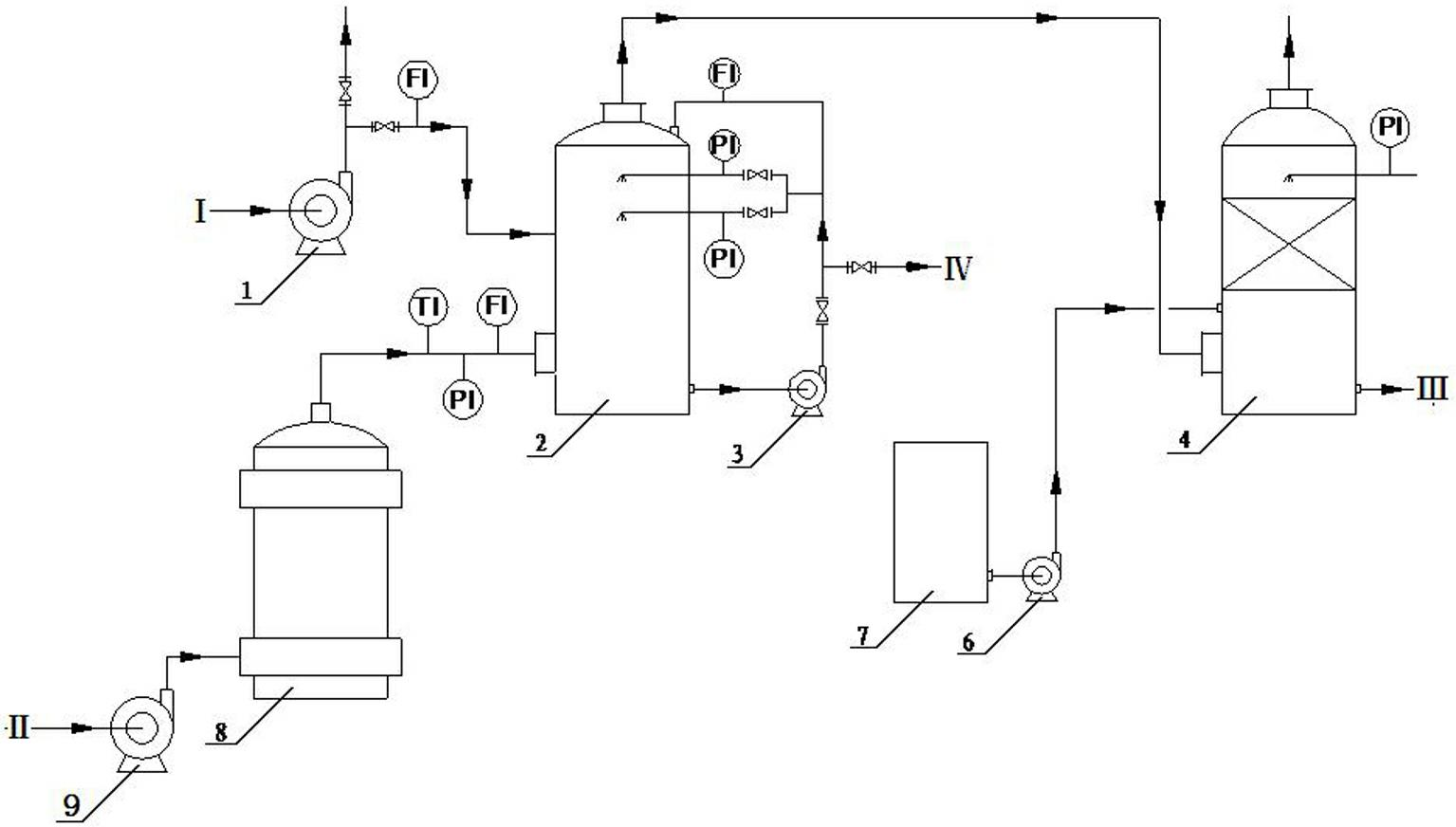

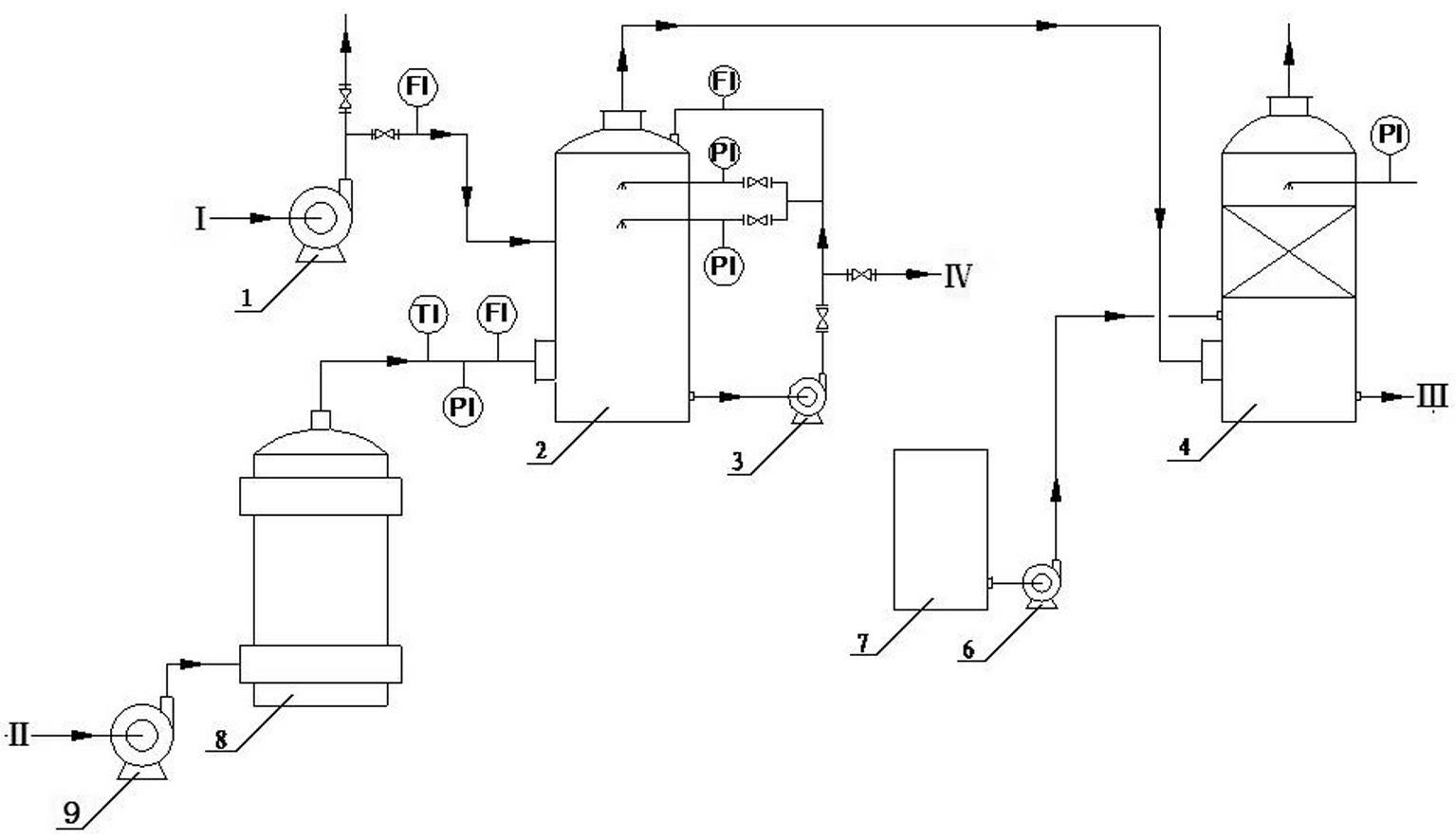

[0014] Hot air concentration method is used to remove F, Cl and As from polluted acid. The flue gas produced in the smelting process of non-ferrous metals is subjected to electrostatic precipitator to make acid. Dilute acid contains F, Cl and As. The removal process is as follows: 1) Air I is blown into the SO through blower 9 3 Cooler 8, using SO 2 converted to SO 3 A large amount of waste heat is released during the process, which converts the air into hot air and enters the bottom of the concentration tower 2; 2) The dirty acid delivery pump 1 pumps the dirty acid II into the top of the concentration tower 2, sprays from the top of the tower, and connects with the bottom-up Full contact with hot air; 3) F and Cl in the polluted acid II combine with water vapor and enter the tail gas scrubber 4 in the form of acid mist, and the lye in the liquid alkali storage tank 7 is pumped into the tail gas scrubber 4 through the liquid alkali delivery pump 6 , neutralized to form salt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com