Hot-wet resistant and aging resistant dual-component condensation type room temperature curing silicone rubber

A room temperature curing, two-component technology, applied in non-polymer adhesive additives, adhesives, adhesive additives, etc., can solve problems such as performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Component A: 50g hydroxyl-terminated polydimethylsiloxane with a viscosity of 20000mPa.s, 50g stearic acid-treated calcium carbonate with an average particle size of 0.06 microns, mix well, three-roll milling, add 3g epoxy resin E51 , mixed evenly, vacuum defoaming.

[0031] Component B: 49g of methyl silicone oil with a viscosity of 10000mPa.s, 10g of pigment carbon black, 20g of ethyl orthosilicate, 1g of dibutyltin dilaurate, 20g of aminopropyltriethoxysilane, mix well, vacuum defoaming, sealed package.

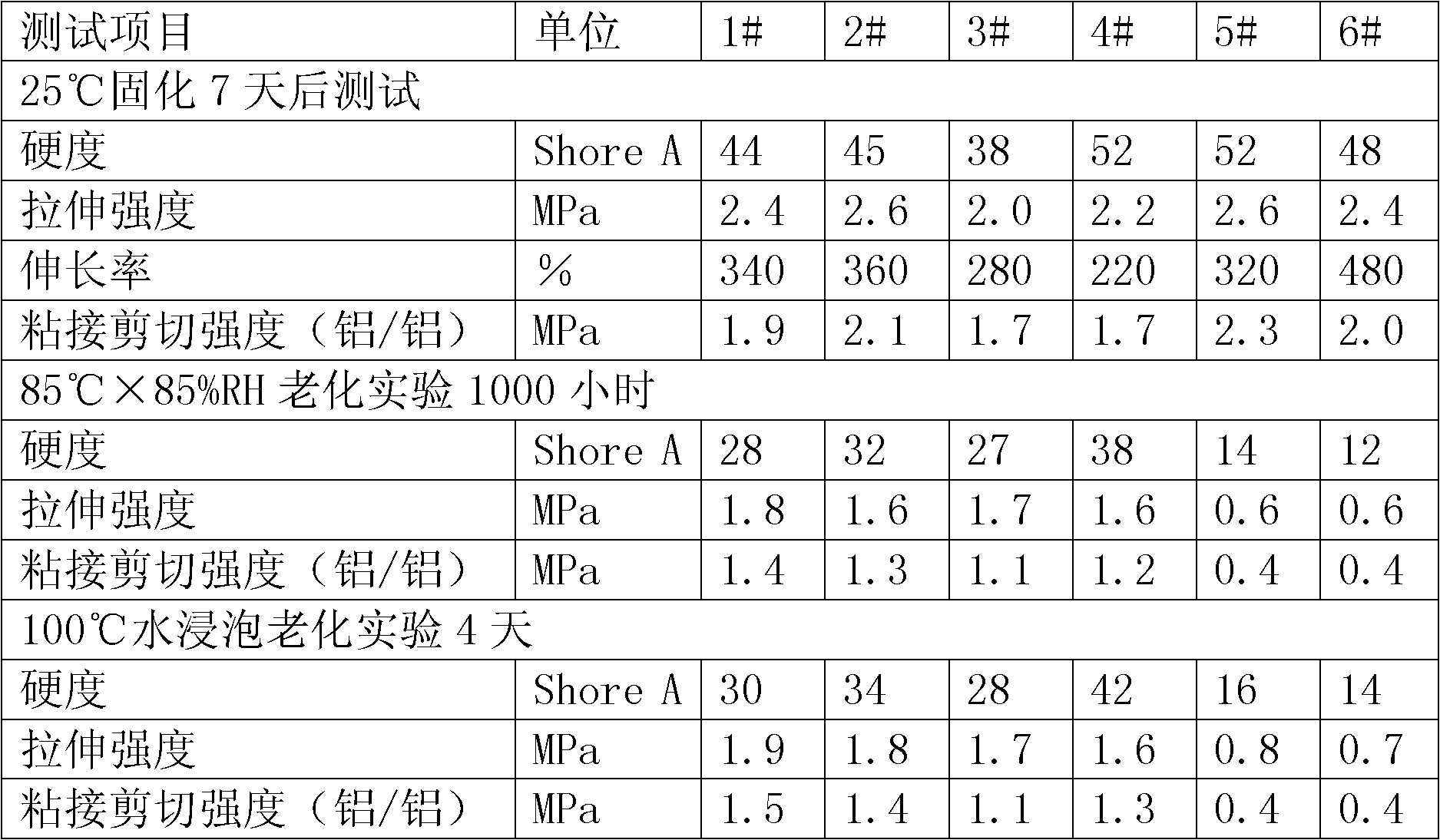

[0032] When using, mix component A and component B uniformly according to the weight ratio of 10:1, and defoam to obtain black two-component room temperature curing condensation type silicone rubber 1#. The results are shown in Table 1.

Embodiment 2

[0034] Component A: 55g of hydroxyl-terminated polydimethylsiloxane with a viscosity of 10000mPa.s, 42g of stearic acid-treated calcium carbonate with an average particle size of 0.08 microns, 3g of titanium dioxide, mix well, three-roll milling, add 2g Glycidyl ether propyl trimethoxysilane, mixed evenly, vacuum defoaming.

[0035] B component: 60g viscosity 5000mPa.s methyl silicone oil, 9g hexamethyldisilazane treatment specific surface area 200m 2 / g of fumed silica, 1g of stannous octoate, 10g of aminopropyltrimethoxysilane, and 20g of partially hydrolyzed oligomer of methyltrimethoxysilane, mixed evenly, vacuum defoamed, and sealed in packaging.

[0036] When using, mix A component and B component according to the weight ratio of 10:1, and defoam to obtain white two-component room temperature curing silicone rubber 2#. The results are shown in Table 1.

Embodiment 3

[0038] Component A: 87g hydroxyl-terminated polydimethylsiloxane with a viscosity of 20000mPa.s, 13g hexamethyldisilazane with a specific surface area of 200m 2 / g of fumed silica, mix evenly, three-roll milling, add 2g allyl glycidyl ether, mix evenly, and vacuum defoam.

[0039] Component B: 55g of methyl silicone oil with a viscosity of 1000mPa.s, 4g of hexamethyldisilazane treated with a specific surface area of 200m 2 / g of fumed silica, 20g of aminoethylaminopropyl triethoxysilane, 20g of propyl orthosilicate, 1g of dibutyltin diacetylacetonate, mixed evenly, vacuum defoamed, sealed and packaged.

[0040] When using, mix component A and component B uniformly according to the weight ratio of 10:1, and defoam to obtain translucent two-component room temperature curing condensation type silicone rubber 3#. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com