Catalyst for preparing bio-diesel, preparation method and application thereof

A biodiesel and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve long reaction time, complicated production process, troublesome post-processing, etc. problem, to achieve the effect of simple preparation method, simple synthesis process and convenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

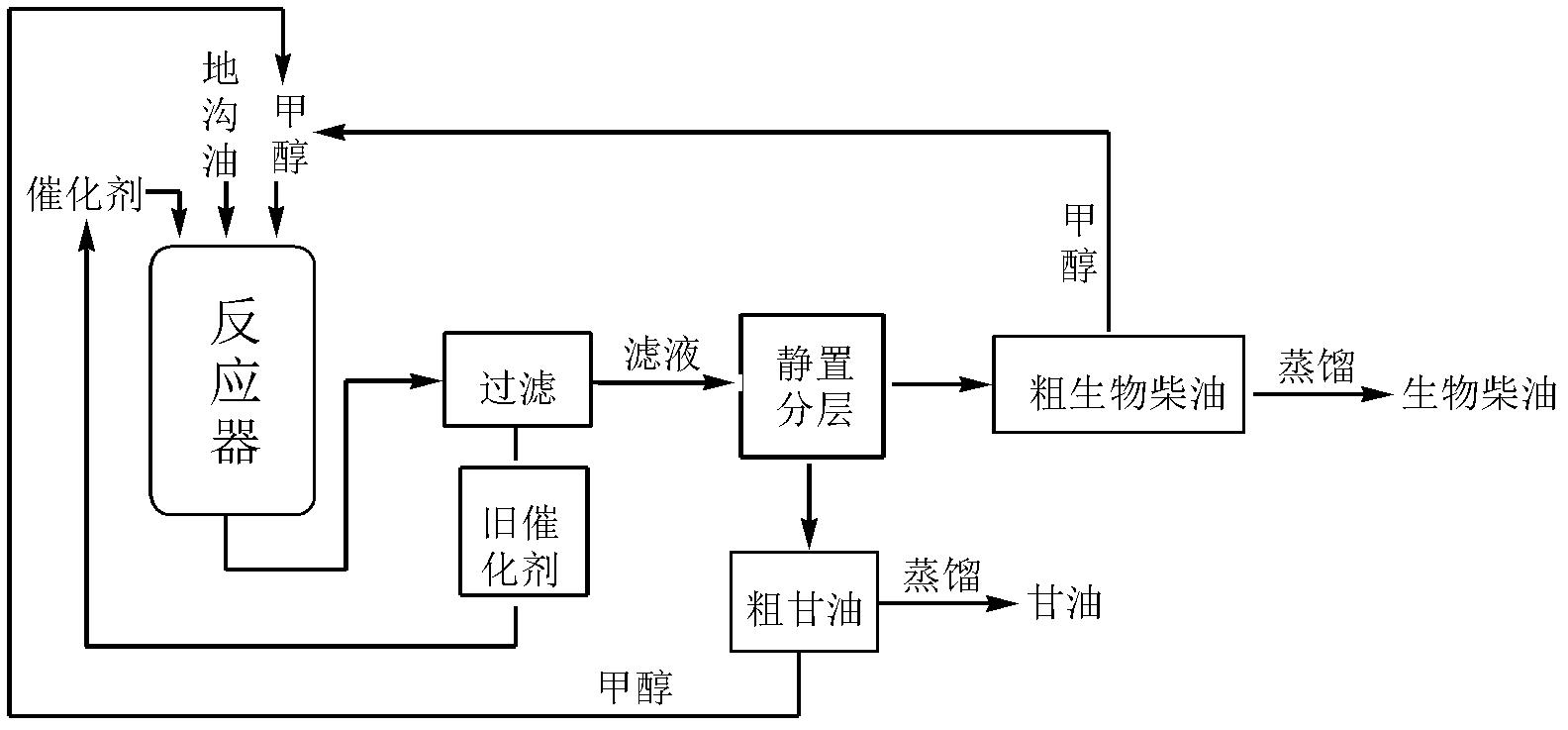

Method used

Image

Examples

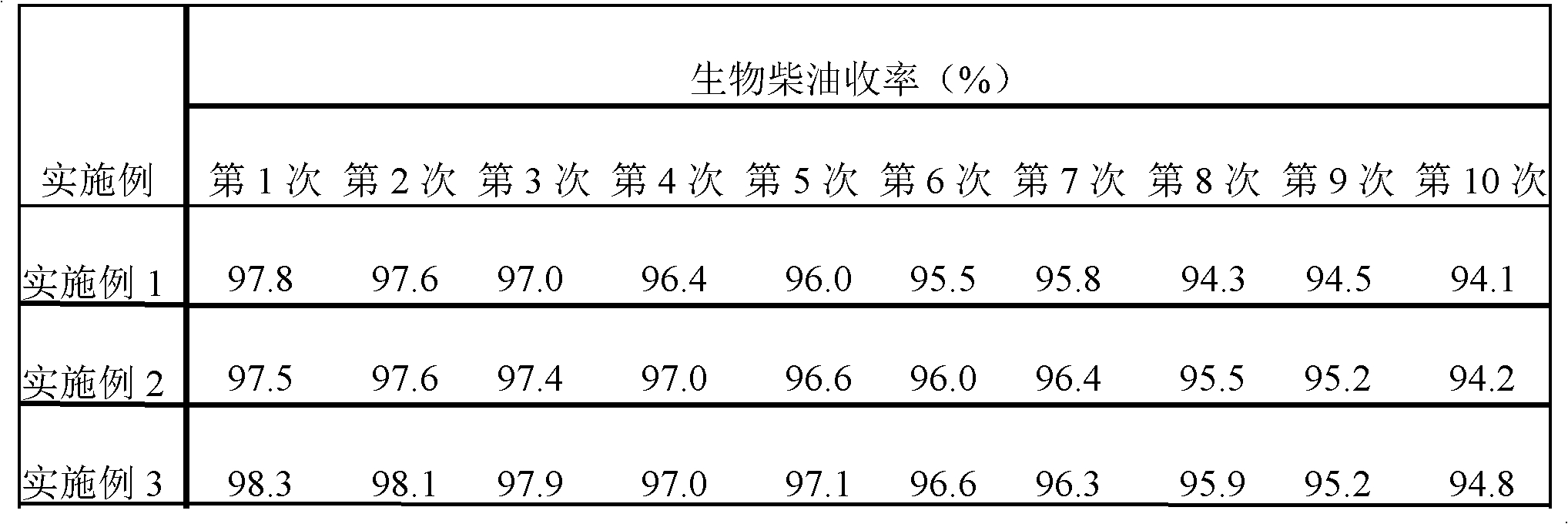

Embodiment 1

[0025] (1) Preparation of catalyst

[0026] The 3.5mol / L ammonium persulfate hydrochloric acid solution (40mL, wherein the mass concentration of HCl in hydrochloric acid is 37.5%) is added dropwise in the 3mol / L aniline hydrochloric acid solution (45mL, wherein the mass concentration of HCl in hydrochloric acid is 37.5%) , stirred at 18°C for 3 hours, filtered, washed the solid until neutral, and dried; soaked the dried solid in 0.12mol / L p-toluenesulfonic acid solution for 23 hours, filtered, and dried at 110°C , to be p-toluenesulfonic acid doped polyaniline catalyst.

[0027] (2) Preparation of biodiesel

[0028] In the reactor equipped with agitator, reflux condensing device, and thermometer, add waste oil (18g) after pretreatment, methanol (3g, the mass ratio of oil and methanol is 1:0.16) and catalyst (0.63g, the total mass of raw materials 3%), heated to 65 ° C, stirred and refluxed for 3 hours. After the reaction is finished, cool, filter, and filter out the catal...

Embodiment 2

[0032] (1) Preparation of catalyst

[0033] 3mol / L ammonium persulfate hydrochloric acid solution (45mL, wherein the mass concentration of HCl in hydrochloric acid is 37.0%) was added dropwise to 3.5mol / L aniline hydrochloric acid solution (40mL, wherein the mass concentration of HCl in hydrochloric acid was 37.0%) , stirred at 16°C for 4 hours, filtered, washed the solid until neutral, and dried; soaked the dried solid in 0.10mol / L p-toluenesulfonic acid solution for 20 hours, filtered, and dried at 100°C , to be p-toluenesulfonic acid doped polyaniline catalyst.

[0034] (2) Preparation of biodiesel

[0035] In the reactor equipped with stirrer, reflux condensing device, thermometer, waste oil (36g) after adding the pretreatment, methanol (7g, oil and methanol mass ratio are 1: 0.19) and catalyst (1.50g, raw material gross mass 3.5%), heated to 60 ° C, stirred and refluxed for 3 hours, the reaction solution was cooled to room temperature, filtered, and the catalyst was fil...

Embodiment 3

[0037] (1) Preparation of catalyst

[0038] 3.5mol / L ammonium persulfate hydrochloric acid solution (43mL, wherein the mass concentration of HCl in hydrochloric acid is 37.5%) was added dropwise to 4mol / L aniline hydrochloric acid solution (50mL, wherein the mass concentration of HCl in hydrochloric acid was 37.0%) , stirred at 14°C for 4 hours, filtered, washed the solid until neutral, and dried; soaked the dried solid in 0.14mol / L p-toluenesulfonic acid solution for 24 hours, filtered, and dried at 110°C , to be p-toluenesulfonic acid doped polyaniline catalyst.

[0039] (2) Preparation of biodiesel

[0040] In the reactor that stirrer, reflux condensing device, thermometer are housed, waste oil (54g) after adding the pretreatment, methanol (12g, oil and methanol mass ratio are 1: 0.22) and catalyst (2.64g, raw material total mass 4%), heated to 70°C, stirred and refluxed for 3.5 hours, the reaction liquid was cooled to room temperature, filtered, and the catalyst was filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com