Method for preparing TiB2/TiC (titanium diboride/titanium carbide) ultrafine powder for surface spraying of engine piston ring by means of high energy ball milling

A technology of high-energy ball milling and surface spraying, which is applied in the direction of coating, molten spraying, metal material coating technology, etc., can solve problems such as not being ideal, and achieve the effects of increased productivity, cheap reaction raw materials, high hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] ① Combine Ti and B 4 C is weighed according to the molar ratio of 3:1, a total of 50g, and dried at 80°C for 20 hours for later use;

[0018] ② Weigh stainless steel balls with diameters of 6, 10, 12, and 20mm according to the ball-to-material ratio of 10:1, totaling 500g, and set aside;

[0019] ③Select a 250Ml stainless steel ball mill tank, first put the reactants into the stainless steel tank, and then put the balls on the powder, almost except for some gaps, which can completely cover the powder, the balls account for about 2 / 3 of the volume of the ball mill tank , then put the head of the argon tube deep into the top layer of balls along the inner wall of the ball mill tank, the argon flow rate and pressure are 0.1Mpa, remove it after 10 minutes, and seal the ball mill tank;

[0020] ④ Select the rotational speed as 300r / min, ball mill for 60 hours, and set the machine to mill for half an hour and rest for half an hour;

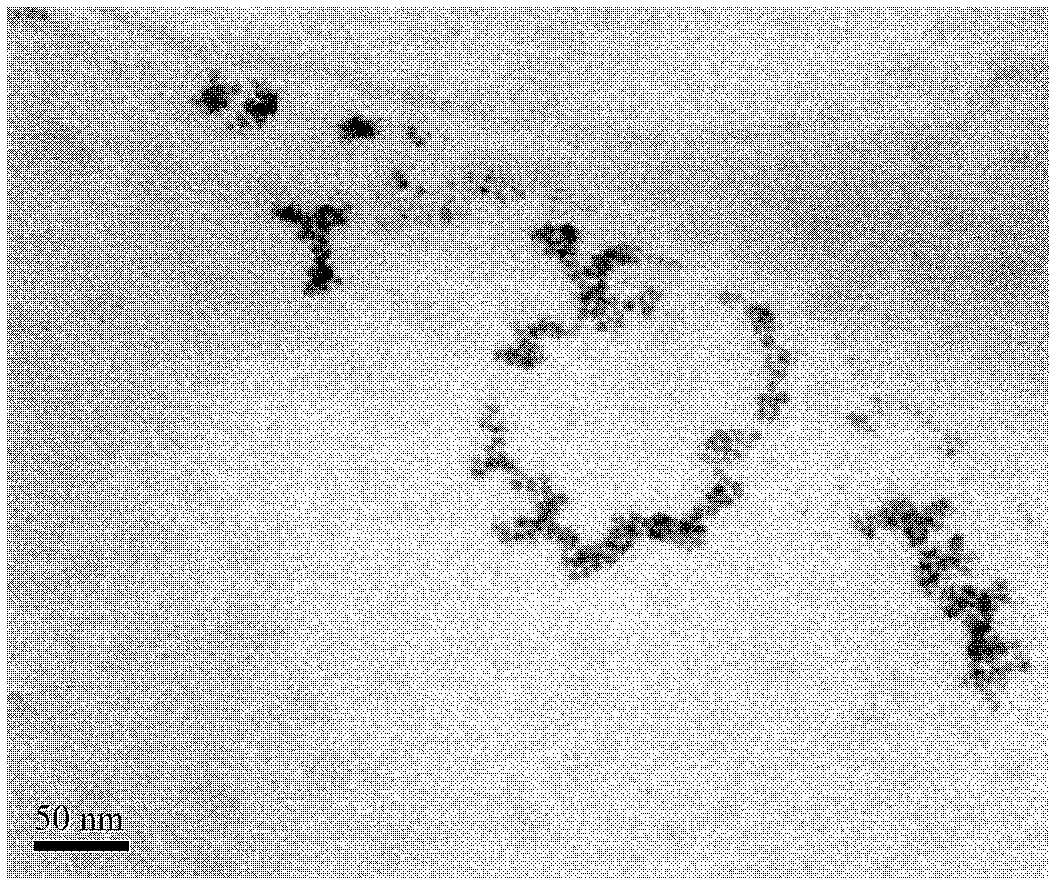

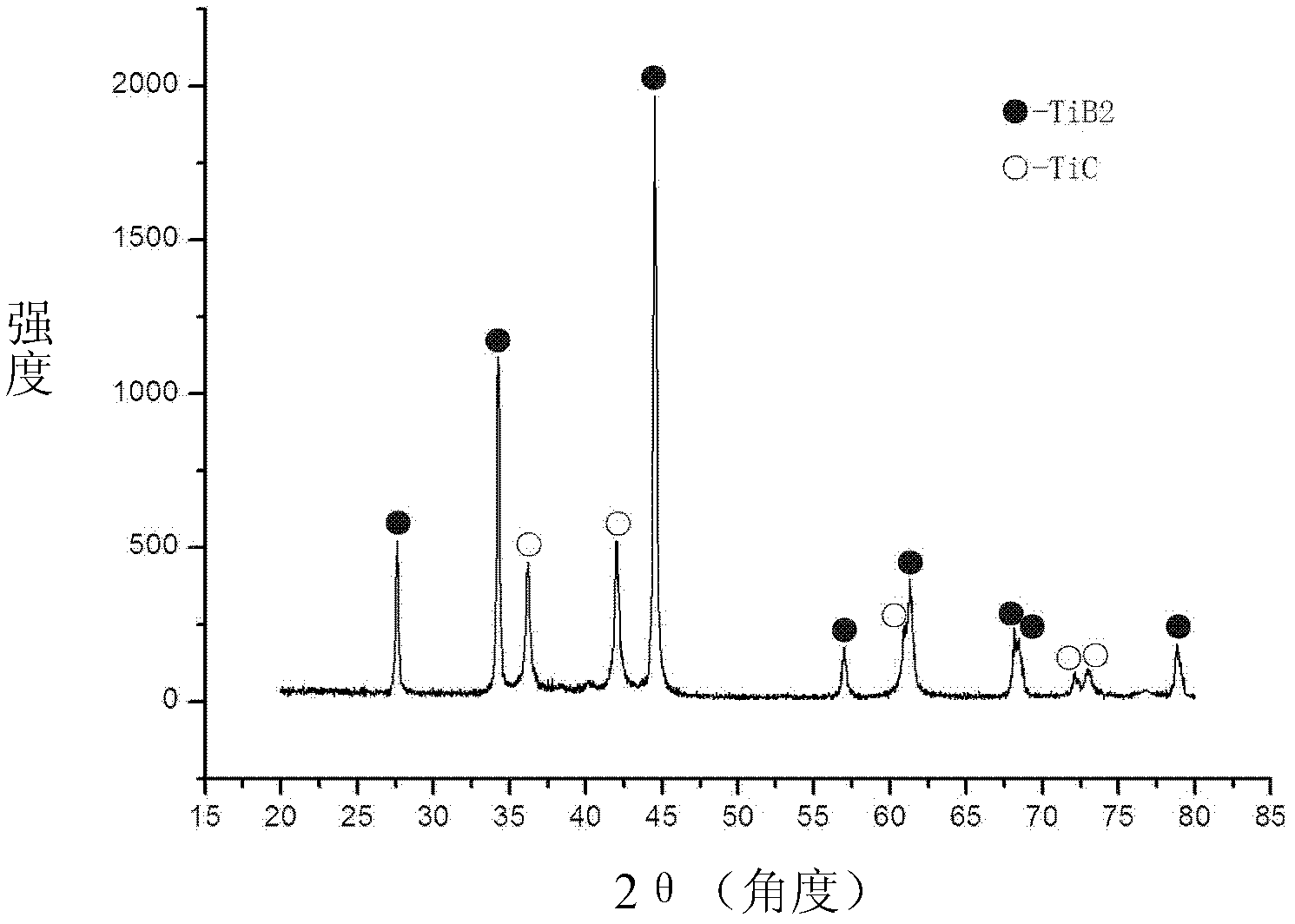

[0021] ⑤ After 60 hours, open the ball m...

Embodiment 2

[0023] ① Combine Ti and B 4 C is weighed according to the molar ratio of 3:1, a total of 50g, and dried at 80°C for 20 hours for later use;

[0024] ② Weigh stainless steel balls with diameters of 6, 8, 12, and 20 mm according to the ball-to-material ratio of 10:1, totaling 500 g, and set aside;

[0025] ③Select a 250Ml stainless steel ball mill tank, first put the reactants into the stainless steel tank, and then put the balls on the powder, almost except for some gaps, which can completely cover the powder, the balls account for about 2 / 3 of the volume of the ball mill tank , then put the head of the argon tube deep into the top layer of balls along the inner wall of the ball mill tank, the argon flow rate and pressure are 0.1Mpa, remove it after 10 minutes, and seal the ball mill tank;

[0026] ④ Select the rotational speed as 400r / min, ball mill for 40 hours, and set the machine to ball mill for half an hour and rest for half an hour;

[0027] ⑤ After 40 hours, open the ...

Embodiment 3

[0029] ① Combine Ti and B 4 C is weighed according to the molar ratio of 3:1, a total of 50g, and dried at 80°C for 20 hours for later use;

[0030] ② Weigh stainless steel balls with diameters of 6, 8, 10, and 20 mm according to the ball-to-material ratio of 15:1, totaling 750 g, and set aside;

[0031] ③Select a 250Ml stainless steel ball mill tank, first put the reactants into the stainless steel tank, and then put the balls on the powder, almost except for some gaps, which can completely cover the powder, the balls account for about 2 / 3 of the volume of the ball mill tank , then put the head of the argon tube deep into the top layer of balls along the inner wall of the ball mill tank, the argon flow rate and pressure are 0.1Mpa, remove it after 10 minutes, and seal the ball mill tank;

[0032] ④ Select the rotational speed as 500r / min, ball mill for 20 hours, and set the machine to ball mill for half an hour and rest for half an hour;

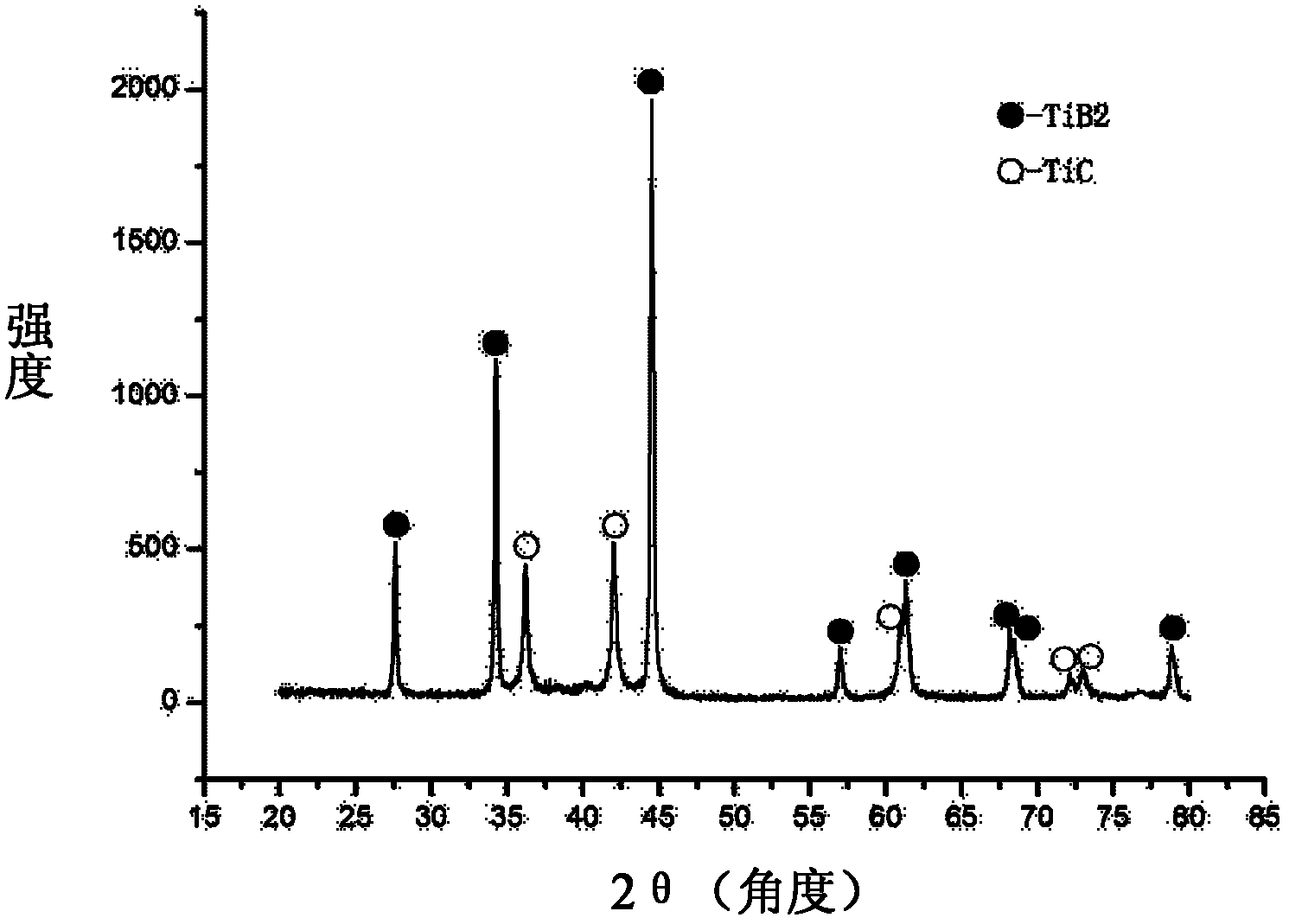

[0033] ⑤After 20 hours, open the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com