Integrated coking wastewater/excess sludge synchronous treatment method and treatment device

A technology for coking wastewater and excess sludge, which is applied in sludge treatment, biological sludge treatment, aerobic and anaerobic process treatment, etc. It can solve the problems of complex treatment process, high energy consumption, and failure to meet the requirements of low-carbon economy , to achieve the effect of tight bacterial arrangement, rich bacterial species, and strengthened dominant culture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

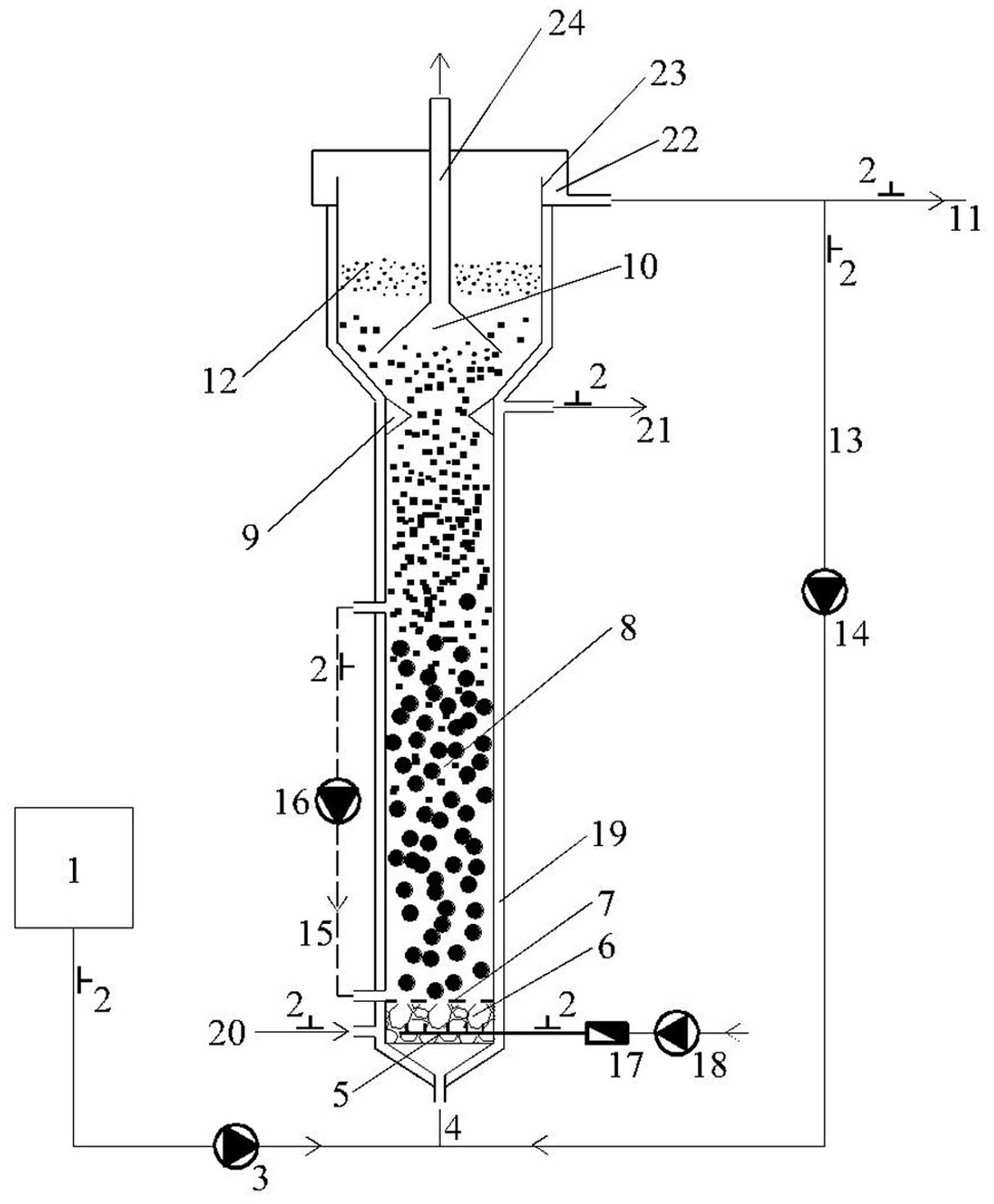

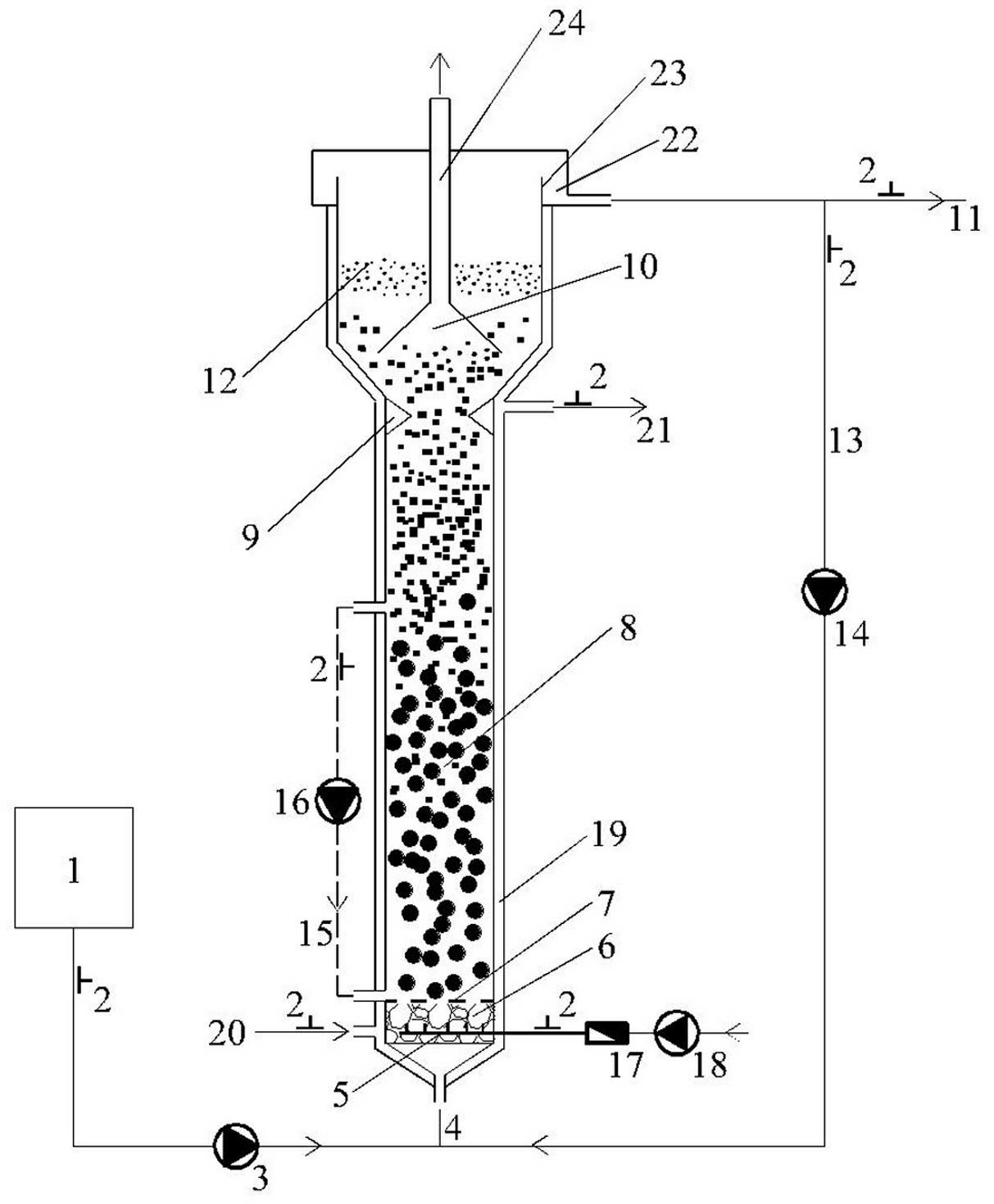

[0054] Integrated coking wastewater / excess sludge synchronous treatment device such as figure 1 As shown, it consists of a double-expansion granular sludge reactor 8 and a waste water storage tank 1.

[0055] The double-expanded granular sludge reactor 8 is made of plexiglass. The whole reactor is divided into three parts: the aeration distribution chamber 6, the reaction area and the sedimentation area 12. Among them, the aeration distribution chamber 6 is located at the bottom of the reactor, with an inner diameter of 100 mm and a height of 0.2m, volume 1.5L; most of the reactor is the reaction zone, located in the middle of the reactor, with an inner diameter of 100mm, a height of 1.7m, and a volume of 12L; the precipitation zone 12 is located at the top of the reactor, with an inner diameter of 140mm, a height of 0.6m, and a volume of 6L.

[0056] In the reaction zone of the reactor, the filamentous bacteria used to degrade the pollutants in the wastewater moderately grow ...

Embodiment 2

[0070] Take the dewatered sludge cake of a sewage treatment plant in Taiyuan City for activity recovery and then inoculate it into the reactor of Example 1, and add a small amount of loose granular sludge as sludge, and take domestic sewage from a living quarter in Taiyuan City at about 35 °C Rapid domestication and cultivation of granular sludge under mesophilic conditions. Influent COD is 149-615mg·L -1 After about 60 days, the start-up was successful, the granular sludge was basically formed, the weight percentage of particles larger than 0.45mm reached 57%, and the methane-producing activity of the sludge reached 0.58gCODCH 4 · gVSS -1 d -1 , the COD removal rate remained at about 62%, and the organic load reached 6.9kgCOD·m -3 .d -1 about.

[0071] The next step is to form a double-expanded granular sludge bed and simultaneously cultivate key bacteria that can simultaneously treat coking wastewater and excess sludge. Coking wastewater was taken from a coking plant i...

Embodiment 3

[0074] Get the dewatered sludge of a sewage treatment plant in Taiyuan and inoculate it into the reactor of Example 1 after the activity recovery. The coking wastewater is taken from a coking plant in Taiyuan City. The concentrations of influent COD, ammonia nitrogen, phenols, SCN and CN are respectively 630-950mg·L -1 , 69-182mg·L -1 , 10.8-200.3mg·L -1 , 66.7-577.7mg·L -1 , 0.49-57.8mg·L -1. Using self-prepared beer wastewater, and adding a small amount of loose granular sludge as sludge, start the operation at 35°C, maintain HRT3.4h, and reduce the influent COD from 200mg·L within a week -1 Increase to 1000mg·L -1 , the influent load is 1.58kgCOD·m -3 d -1 Increase to 7.5kgCOD·m -3 d -1 , the granular sludge was rapidly formed in about 10 days, and the sludge concentration reached 32.7g·L -1 , VSS / SS reached 0.66, and the COD removal rate reached 94.7%.

[0075] Directly use coking wastewater to domesticate granular sludge, adopt continuous micro-aerobic aeration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Active | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com