Method for preparing microporous adsorbent from sludge, product and special equipment

A microporous adsorbent and sludge technology, applied in the field of skeleton, can solve the problems of decolorization rate and heavy metal removal rate, far poor specific surface area adsorption effect, limited commercial application range, low product added value, etc., and achieve good mechanical strength. , the effect of long service life and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

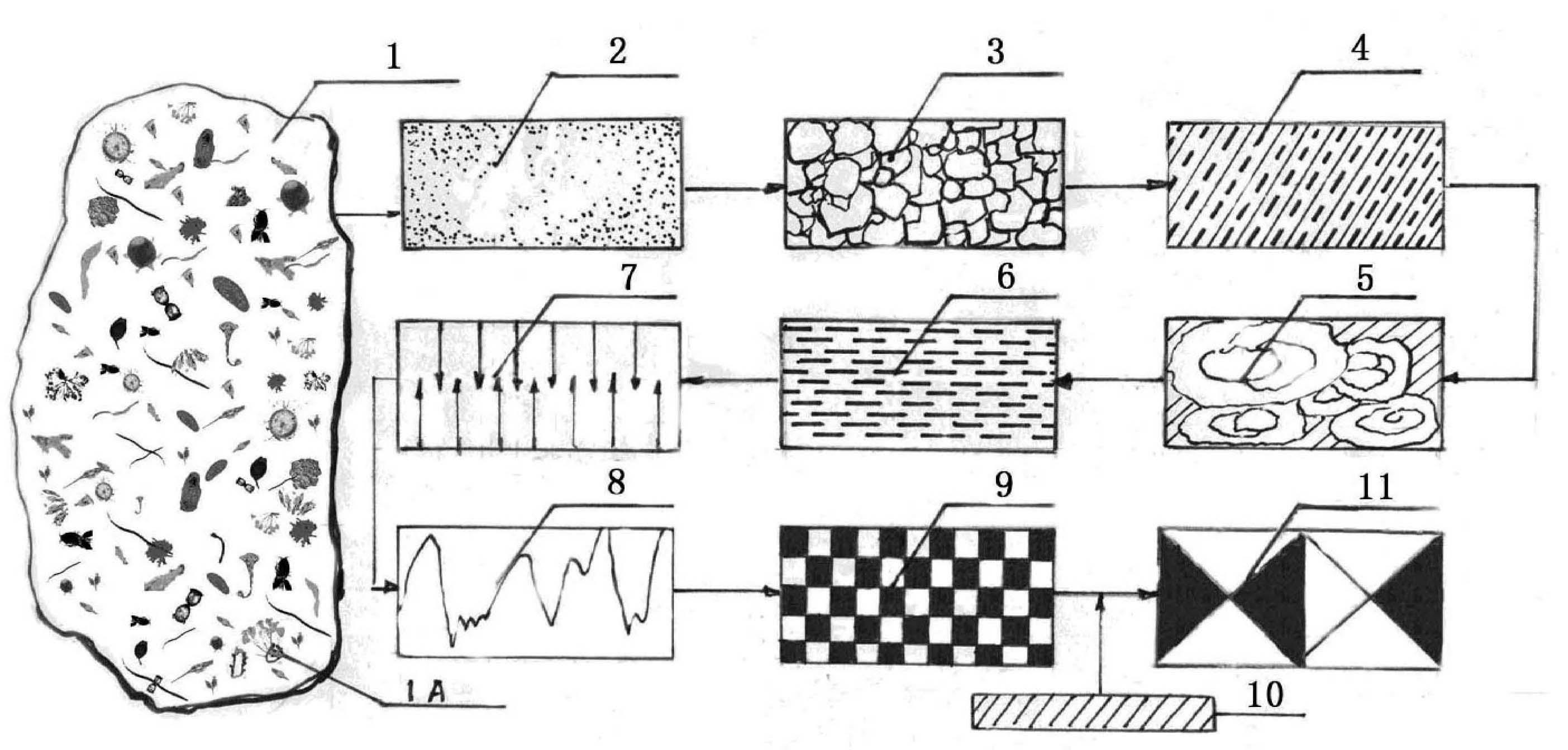

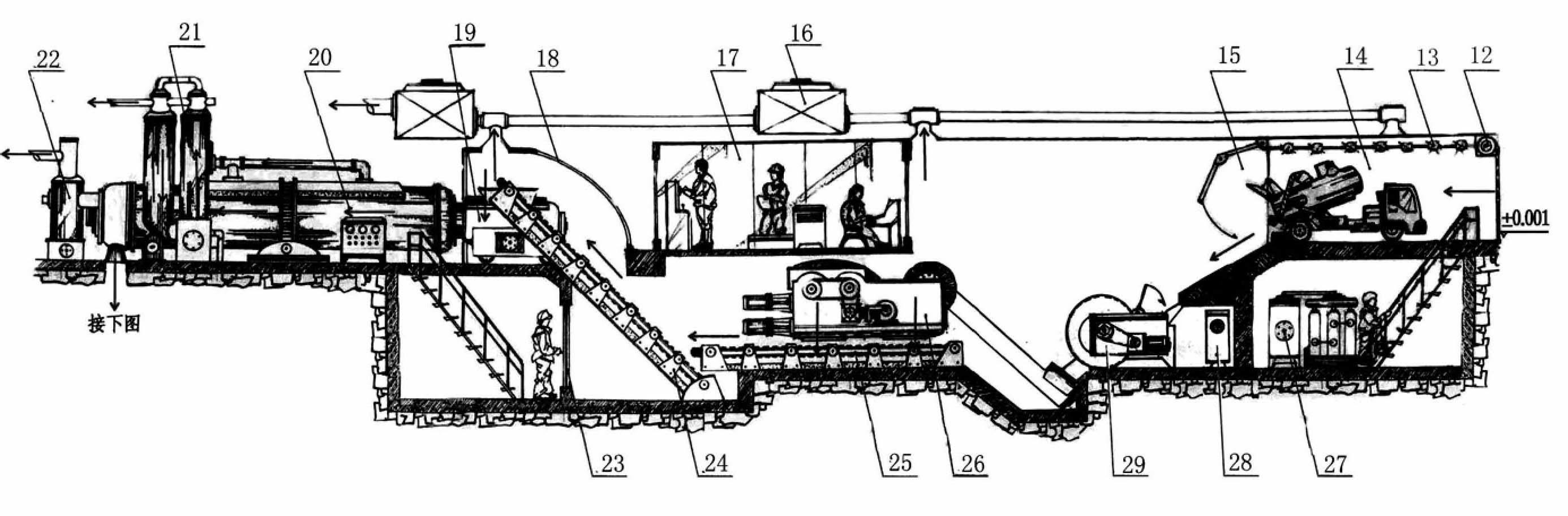

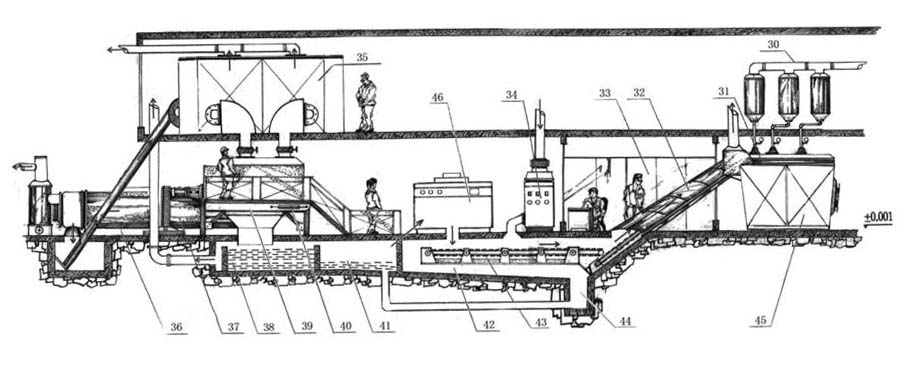

Method used

Image

Examples

Embodiment 1

[0071] Embodiment one: the method comprises the following steps:

[0072] A. The sludge with a water content of 10% (the specific water content of the sludge can be determined according to its specific conditions) is used as a raw material, put into an ozone processor to artificially inactivate microorganisms, and perform oxidation treatment. The treatment process is at room temperature Under normal pressure, the ozone concentration generated by the ozone generator is 5g / L, the ozone flow rate is 8L / min, and the reaction time is 15min. collection and processing;

[0073] B. Send the sludge that has been artificially inactivated into the primary solidification equipment, add calcium oxide accounting for 5% of the sludge weight, and mix it evenly with the sludge. The mixing time is 20 minutes;

[0074] C. The mixed sludge is released from the discharge port and directly sent to the pyrolysis reactor at a feed rate of 20kg per minute. When the sludge enters the pyrolysis reactor...

Embodiment 2

[0081] Embodiment two: the method comprises the following steps:

[0082] A. The sludge with a water content of 20% (the water content of the sludge can be determined according to its specific conditions) is used as a raw material, and it is put into an ozone processor for artificial forced inactivation of microorganisms and oxidation treatment. The treatment process is at room temperature Under normal pressure, the ozone concentration generated by the ozone generator is 7 g / L, the ozone flow rate is 5L / min, and the reaction time is 16 minutes. The oxidation method adopts top-down contact with ozone in reverse circulation, and the generated ozone tail gas is collected by ozone Equipment collection and processing;

[0083] B. Send the sludge that has been artificially inactivated into the primary solidification equipment, add calcium oxide accounting for 10% of the sludge weight, and mix it evenly with the sludge. The mixing time is 21 minutes;

[0084] C. The mixed sludge is ...

Embodiment 3

[0091] Embodiment three: the method comprises the following steps:

[0092] A. Sludge with a water content of 35% (the water content of the sludge can be determined according to its specific conditions) is used as a raw material, put into an ozone processor to artificially inactivate microorganisms, and perform oxidation treatment. The treatment process is at room temperature Under normal pressure, the ozone concentration generated by the ozone generator is 9 g / L, the ozone flow rate is 6.5L / min, and the reaction time is 18 minutes. Collection and processing of collection equipment;

[0093] B. Send the sludge that has been artificially inactivated into the primary solidification equipment, add calcium oxide accounting for 15% of the sludge weight, and mix it evenly with the sludge. The mixing time is 23 minutes;

[0094] C. The mixed sludge is released from the discharge port and directly sent to the pyrolysis reactor at a feed rate of 50kg per minute. When the sludge enters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com