Method for preparing desulfurized gypsum

A technology of desulfurization gypsum and desulfurization slurry, which is applied in the field of flue gas desulfurization, and can solve problems such as affecting vacuum filtration, high viscosity, and inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

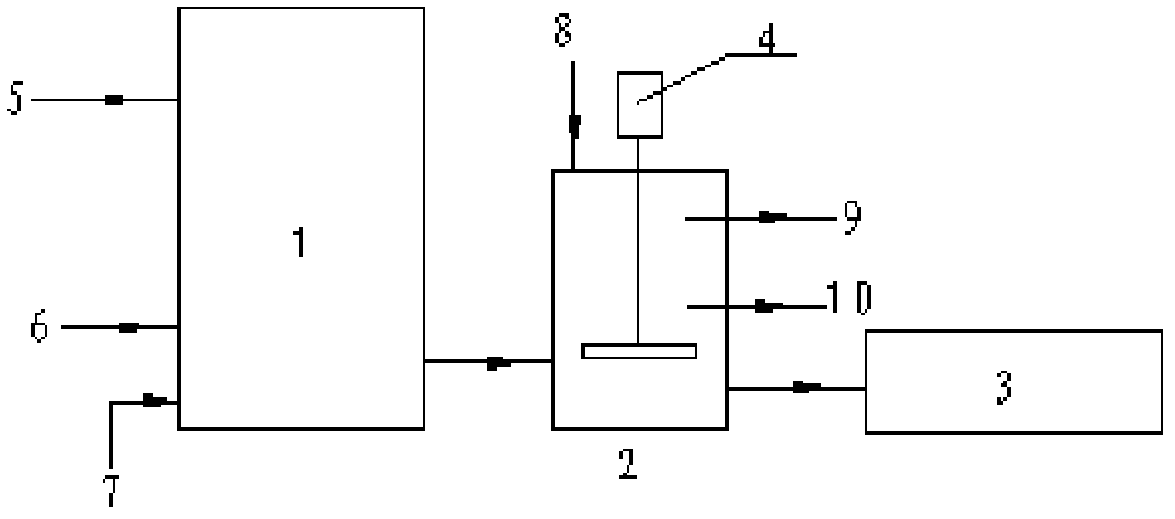

[0026] use as figure 1 In the process shown, the desulfurization system is a limestone-gypsum desulfurization system. Sodium dodecylbenzenesulfonate is added to the desulfurization slurry. After the addition, the concentration of sodium dodecylbenzenesulfonate in the slurry is 0.03g / L. The density of the slurry at the bottom of the separation tank is 1.21g / ml, and the vacuum belt filter is used for suction filtration. The obtained desulfurization gypsum filter cake has a moisture content of 10.8% and a gypsum purity of 94%.

Embodiment 2

[0028] use as figure 1 In the process shown, the desulfurization system is a limestone-gypsum desulfurization system. Sodium dodecylbenzenesulfonate is added to the desulfurization slurry. After the addition, the concentration of sodium dodecylbenzenesulfonate in the slurry is 0.05g / L. The density of the slurry at the bottom of the separation tank is 1.15g / ml, and the vacuum belt filter is used for suction filtration. The obtained desulfurization gypsum filter cake has a moisture content of 10.4% and a gypsum purity of 96%.

Embodiment 3

[0030] use as figure 1 In the process shown, the desulfurization system is calcium carbide slag-gypsum desulfurization system. Sodium lauryl sulfate is added to the desulfurization slurry. min, the density of the gypsum slurry at the bottom of the separation tank was 1.24g / ml, and a vacuum belt filter was used for suction filtration. The obtained desulfurized gypsum filter cake had a moisture content of 9.8% and a gypsum purity of 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com