Integrated industrial production method for producing iminostilbene by continuous catalytic deamination and catalytic dehydrogenation of 2,2'-diamino-bibenzyl

A diaminobibenzyl catalytic deamination and catalytic dehydrogenation technology, which is applied in the chemical industry, sustainable manufacturing/processing, organic chemistry, etc., can solve the problems of severe decomposition of raw materials and products, low utilization rate, and poor product quality , to achieve the effect of increasing life, improving utilization rate and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

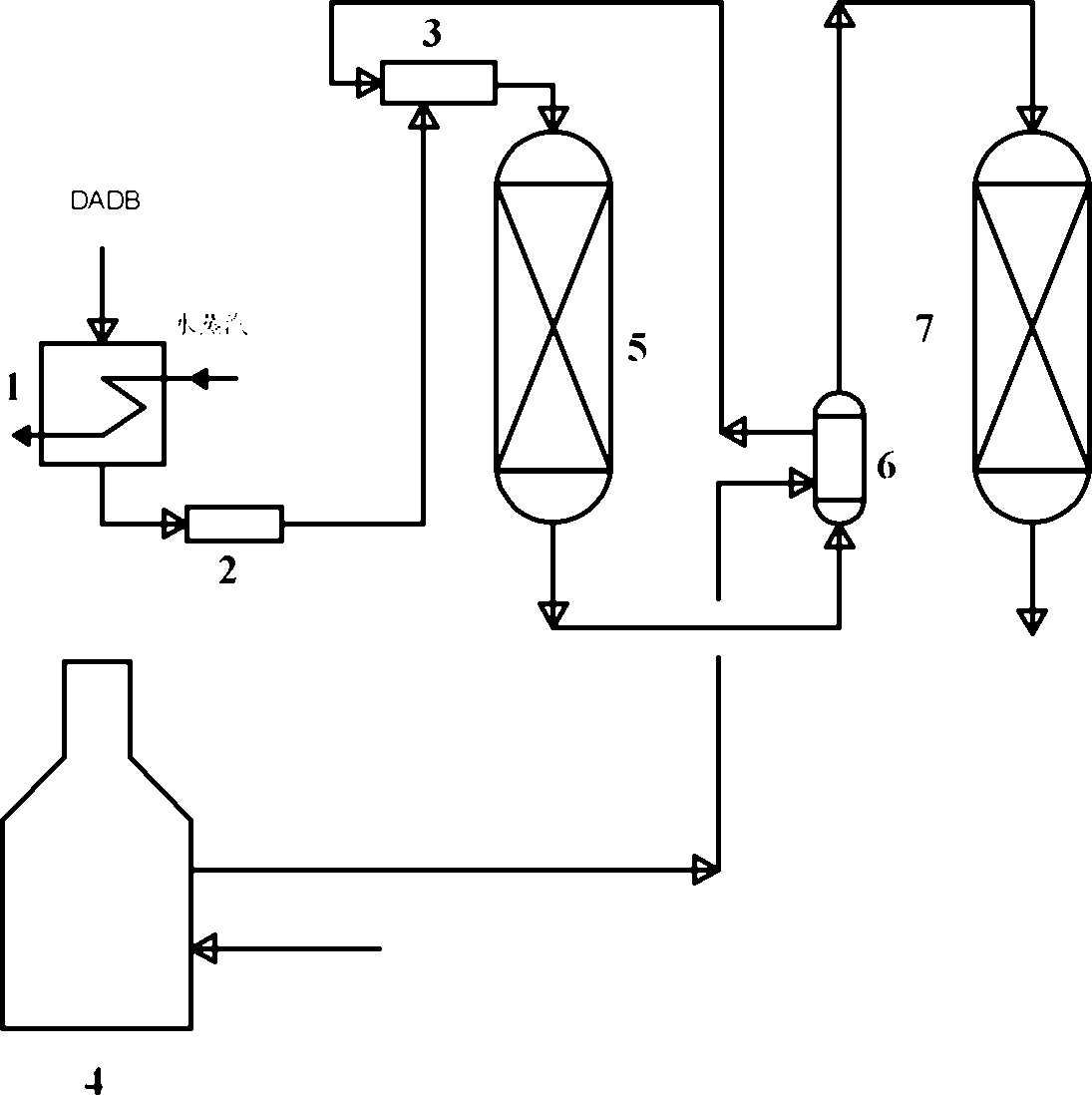

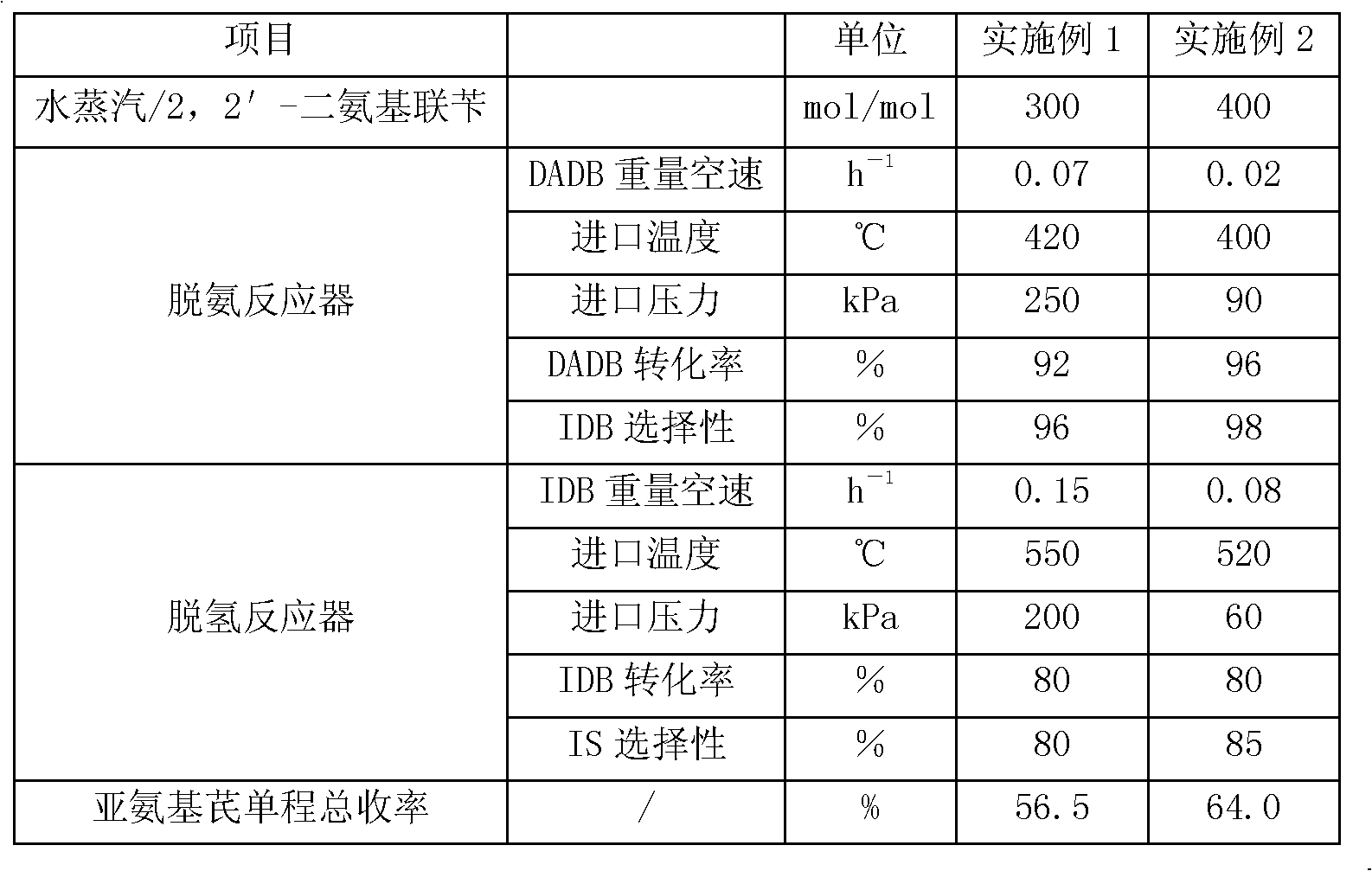

[0036] 2,2′-Diaminobibenzyl gas-phase catalytic deamination and catalytic dehydrogenation to produce iminostilbene and figure 1 The process flow is carried out, the molar ratio of water vapor to 2,2'-diaminobibenzyl is 300, 2,2'-diaminobibenzyl is sent into DADB raw material tank 1, melted under the heating of water vapor, and then passed through DADB The metering pump 2 sends it to the DADB mixer 3; the water is heated to 580°C in the heating furnace 4, sent to the intermediate heat exchanger 6 to heat the product of the deamination reaction, and sent to the DADB mixer 3 after heat exchange. In DADB mixer 3, 2,2'-diaminobibenzyl is mixed with high-temperature steam to reach a deamination reaction temperature of 420°C, and then enters deamination reactor 5 for catalytic deamination reaction, deamination reactor 5 The inlet pressure is 250kPa, and the reaction product enters the intermediate heat exchanger 6 and is heated to a dehydrogenation reaction temperature of 550°C by hi...

Embodiment 2

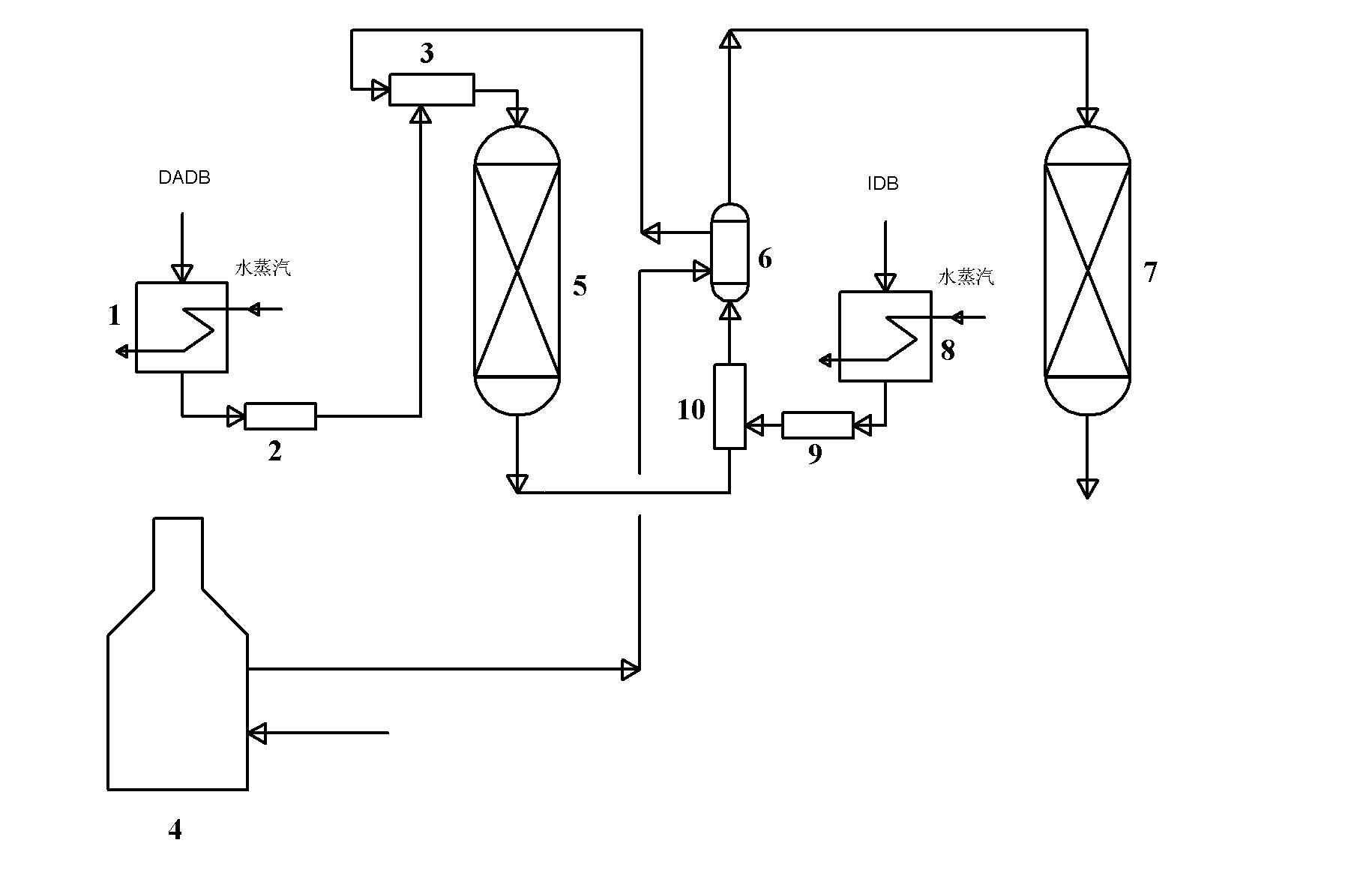

[0038] 2,2′-Diaminobibenzyl gas-phase catalytic deamination and catalytic dehydrogenation to produce iminostilbene and figure 2 The process flow is carried out, the molar ratio of water vapor to 2,2'-diaminobibenzyl is 400, 2,2'-diaminobibenzyl is sent into DADB raw material tank 1, melted under the heating of water vapor, and then passed through DADB The metering pump 2 transports it to the DADB mixer 3; the water vapor is heated to 540°C in the heating furnace 4, sent to the intermediate heat exchanger 6 to heat the product of the deamination reaction, and sent to the DADB mixer 3 after heat exchange. In the DADB mixer 3, 2,2'-diaminobibenzyl is mixed with high-temperature steam to reach a deamination reaction temperature of 400°C, and then enters the deamination reactor 5 for catalytic deamination reaction, and the deamination reactor 5 The inlet pressure is 90kPa, the reaction product is mixed with the recovered intermediate product iminostilbene, then enters the intermed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com