Purifying method for etimicin sulfate

A technology of etimicin sulfate and etimicin sulfate, which is applied in the field of medicine, can solve the problems of high impurity content and low purity of etimicin sulfate, and achieve the goal of improving the purity of finished products, increasing the safety of clinical medication, and reducing adverse reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

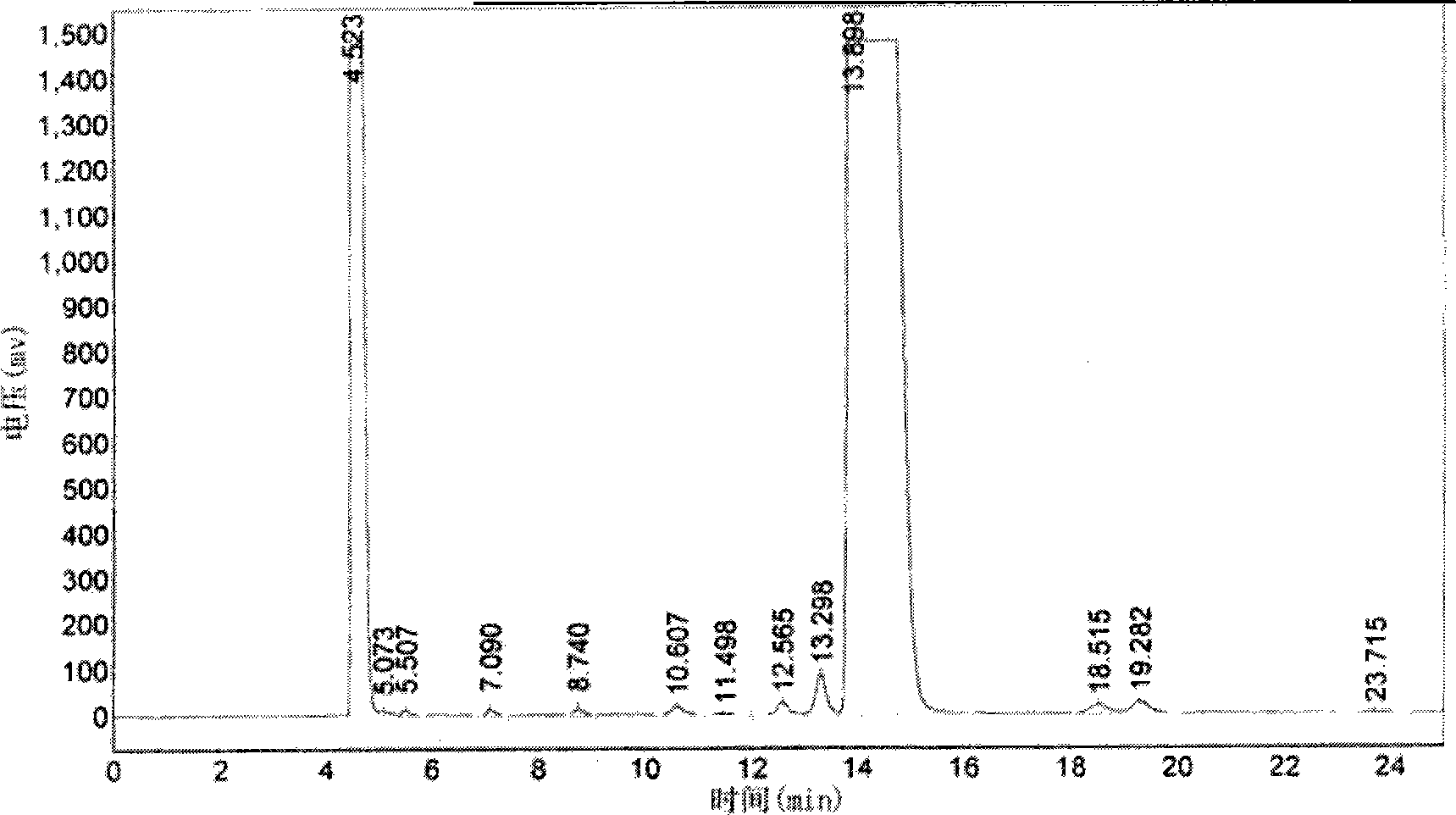

[0051] Example 1. Preparation method of the present invention

[0052] Take the etimicin solution separated by adsorption type macroporous resin with a purity of more than 90% and concentrate it to a concentration of 75% to obtain an etimicin concentrate. Add 30% dilute sulfuric acid with a concentration of 6mol / L to adjust to pH It is 5.8 to obtain etimicin sulfate concentrate, add 30% activated carbon, heat to 70°C, stir and keep for 1 hour, filter to obtain etimicin sulfate refined solution, cool to 2°C at 0.1L / min Slowly add 15L of solvent at the speed of acetone 21%, methanol 15%, ethanol 15%, diethyl ether 17%, ethyl acetate 20%, methyl butanone 12%, while constantly stirring, maintain the stirring speed 280rpm, and The temperature is lowered to 4°C and maintained for 60 minutes to obtain a mother liquor rich in seed crystals. The refined liquid of etimicin sulfate was cooled to 2℃, and added to the mother liquor rich in seed crystals at a rate of 1L / min, while stirring co...

Embodiment 2

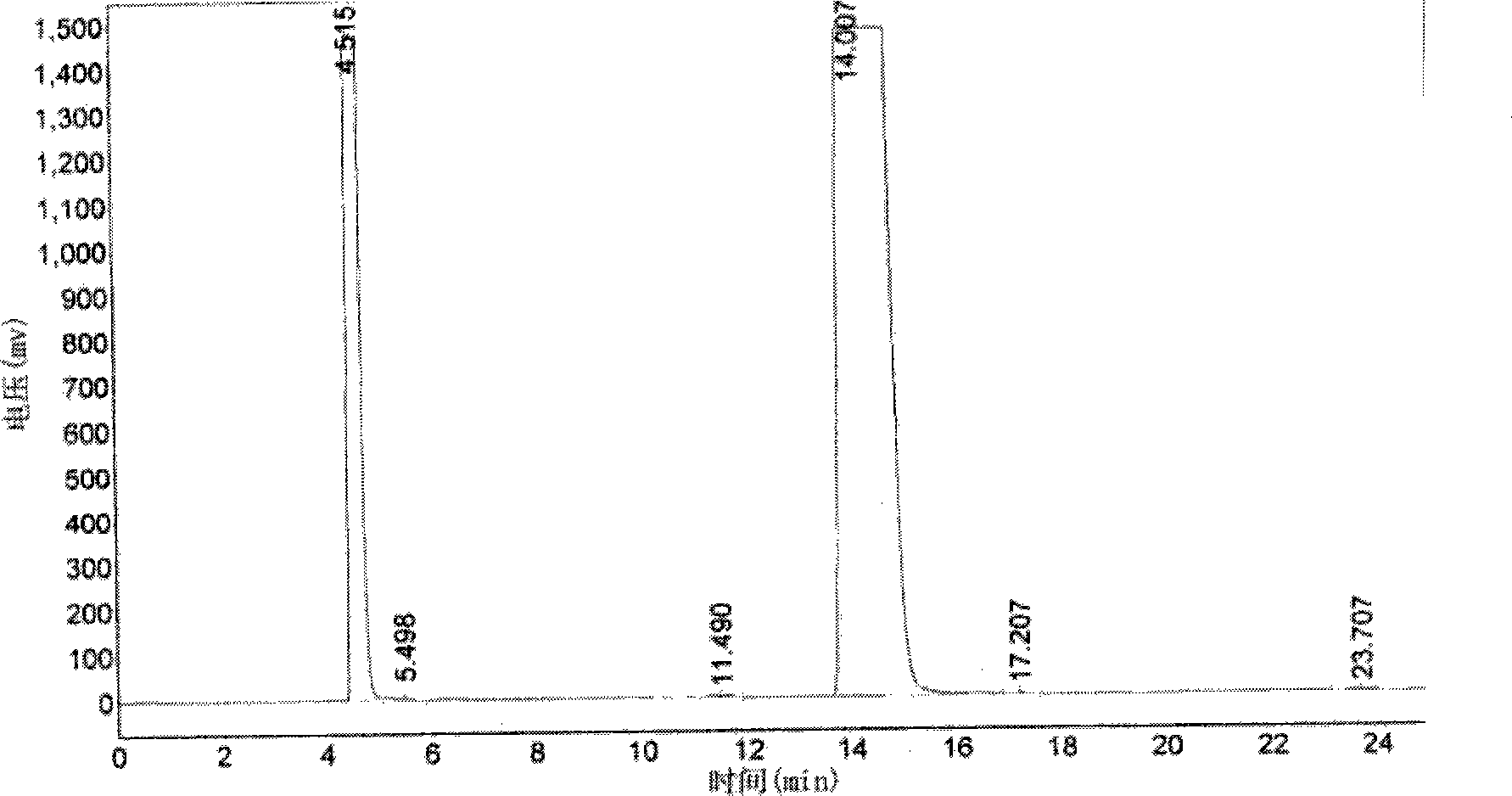

[0053] Example 2. Preparation method of the present invention

[0054] Take the etimicin solution separated by adsorption type macroporous resin with a purity of more than 90% and concentrate it to a concentration of 72% to obtain an etimicin concentrate. Add 33% dilute sulfuric acid with a concentration of 7mol / L to adjust to pH It is 5.9 to obtain etimicin sulfate concentrate, add 33% activated carbon, heat to 75°C, stir and keep for 1.5 hours, filter to obtain etimicin sulfate refined solution, cool to 4°C, at 0.5L / min Add slowly to 18L of solvent at a speed of 5% water, 15% acetone, 10% methanol, 20% ethanol, 17% isopropanol, 21% hexane, and 12% ether. While stirring constantly, maintain the stirring speed at 200rpm , And lower the temperature to 4°C for 90 minutes to obtain a mother liquor rich in seed crystals. The refined liquid of etimicin sulfate was cooled to 4℃, and added to the mother liquor rich in seed crystals at a rate of 3L / min, while stirring continuously, main...

Embodiment 3

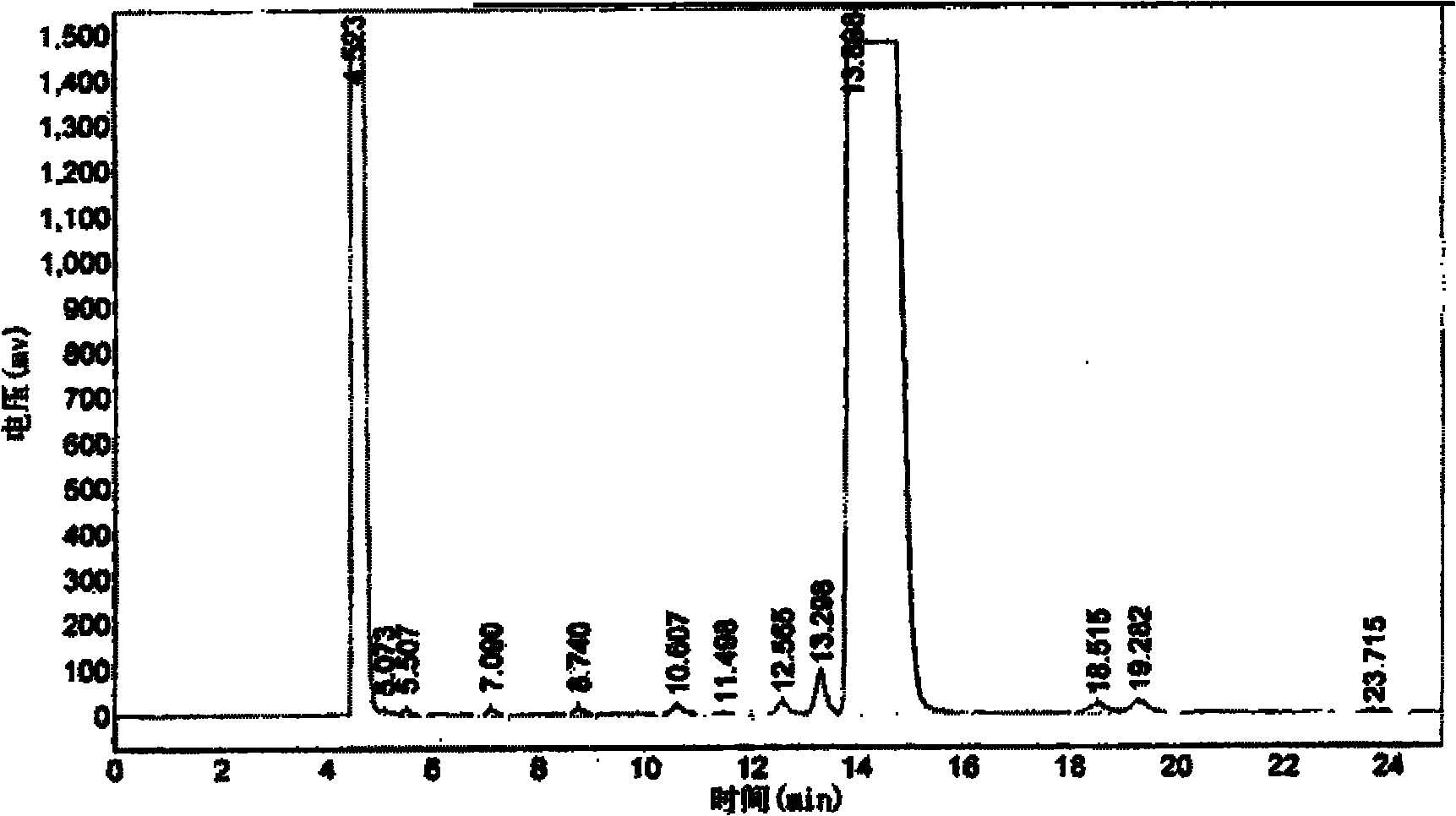

[0055] Example 3. Preparation method of the present invention

[0056] Take the etimicin solution separated by adsorption-type macroporous resin with a purity of more than 90% and concentrate it to a concentration of 70% to obtain an etimicin concentrate. Add 30% 5mol / L dilute sulfuric acid to adjust the pH Is 4.5 to obtain etimicin sulfate concentrate, add 40% activated carbon, heat to 90°C, stir and keep for 2 hours, filter to obtain etimicin sulfate refined solution, cool to 6°C at 0.3L / min Slowly add 20L of solvent, the solvent contains 8% water, 15% acetone, 15% methanol, 10% ethanol, 12% isopropanol, 15% ethyl ether, 10% methyl butanone, ethylene glycol monomethyl ether 15% while continuously stirring, maintaining a stirring speed of 250 rpm, and cooling to 6° C. for 120 minutes to obtain a mother liquor rich in seed crystals. The refined liquid of etimicin sulfate is cooled to 6°C, and added to the mother liquor rich in seed crystals at a speed of 5L / min, while constantly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com