Preparation method of powder lithium electrode

A lithium electrode and powder technology, which is applied in the field of powder lithium electrode preparation, can solve the problems of restricting the rate discharge performance of lithium batteries, poor rate characteristics of metal lithium batteries, and inability to perform high-current discharge, etc., to improve discharge rate characteristics and interface Compatibility, the effect of improving the interface reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

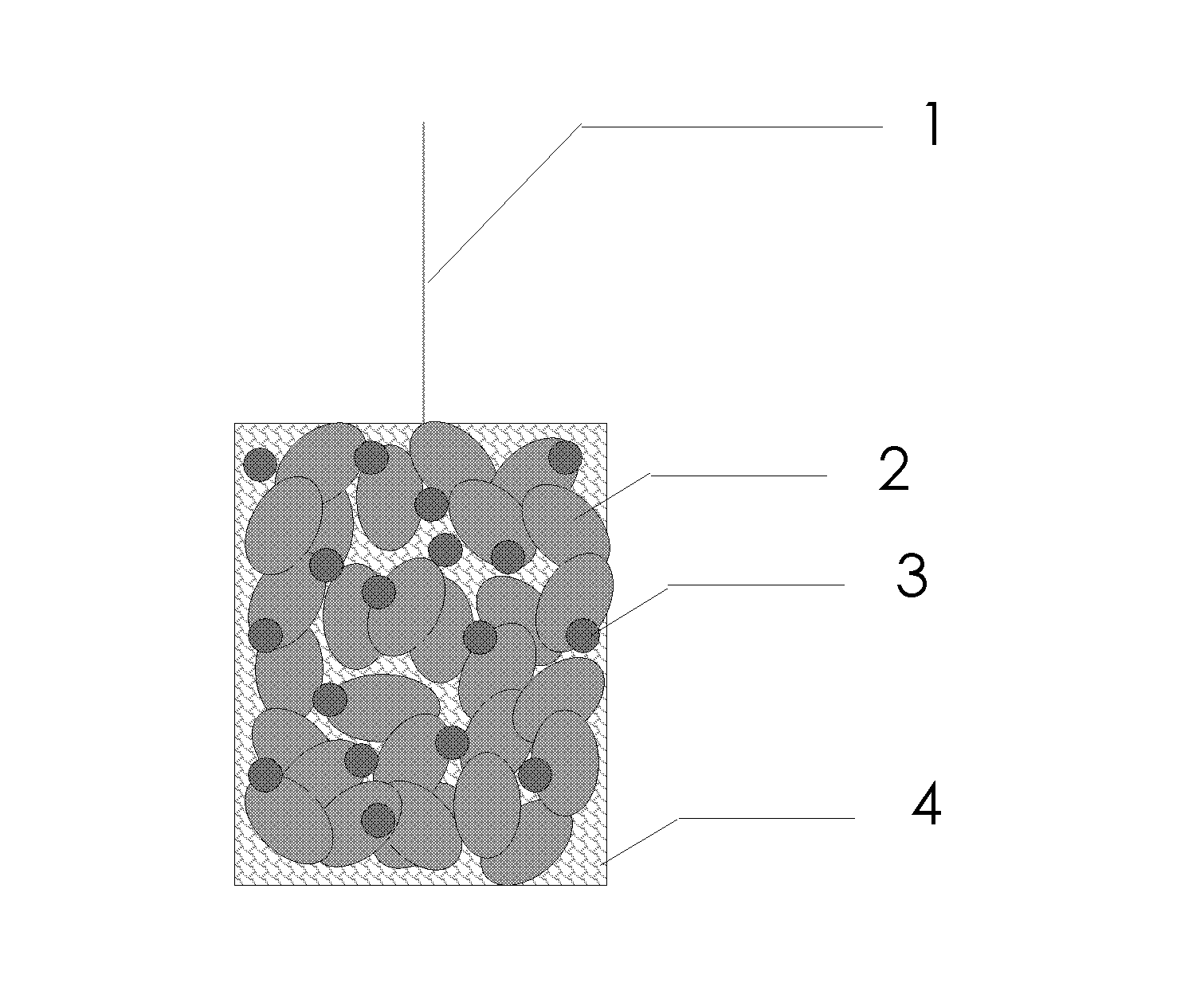

[0024] The preparation process of powder lithium electrode is as follows:

[0025] ⑴ Preparation of powdered lithium

[0026] Under the protection of an inert atmosphere, mix molten metal lithium and hot silicone oil at a volume ratio of 1:40-1:120, pour into a high-speed dispersion mixer, disperse and stir at 600-6000rp / min for 60-180 minutes, and form lithium milk turbid liquid, and then rapidly cool the lithium emulsion to room temperature of 25°C in a rapid cooling machine to form a lithium mixed solution, and then pour the mixed solution into a 40-800 mesh sieve to obtain wet powder lithium; The wet lithium powder is fully cleaned with anhydrous cyclohexane to remove the silicone oil attached to the surface, and then dried in a vacuum oven at 90°C-120°C for 12-24h, and passed through a 40-800 mesh screen to obtain a particle size of 10um - 150um powder lithium 2;

[0027] ⑵ Selection and welding of metal current collector

Embodiment 1

[0034] ⑴ Preparation of powdered lithium

[0035] Under the protection of inert Ar gas, mix molten metal lithium at 185°C-250°C with hot silicone oil at a volume ratio of 1:40-1:120, pour it into a high-speed dispersion mixer, and disperse and stir at 600-6000rp / min for 60-180 Minutes to form a lithium emulsion, then rapidly cool the lithium emulsion to a room temperature of 25°C in a rapid cooler to form a lithium mixture, then pour the mixture into a 40-800 mesh sieve, Wet lithium powder is obtained; the wet lithium powder is fully cleaned with anhydrous cyclohexane to remove the silicone oil attached to the surface, and then dried in a vacuum oven at 90°C-120°C for 12-24h, and passed through a 40-800 mesh screen, Prepare lithium powder with a particle size of 10um-150um;

[0036] ⑵ Selection and welding of metal current collector

[0037] Choose a porosity of 50% to 95%, an area of 10cm 2 -100cm 2 1. Copper foam with a thickness of 1mm-2mm is used as the metal current...

Embodiment 2

[0043] Sieve the lithium powder prepared in Example 1 until the powder lithium with a particle size of 10 um and the conductive carbon powder Super P with a particle size of 1 um to 50 um are evenly mixed at a volume ratio of 9:1, and 1 g to 200 g of the mixed powder is weighed and evenly sprinkled. Fall on the foamed copper surface, all the other steps are identical with embodiment 1, promptly make the powder lithium electrode that is filled in the foamed copper and contain conductive carbon powder Super P.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com