Preparation method of phosphorus adsorption composite material and phosphorus adsorption composite material

A composite material and polymer technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that the adsorbent cannot be recycled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a phosphorus adsorption composite material, comprising:

[0029] Exfoliating the ZnAl layered double metal hydroxide in a stripping solvent to obtain a stripped ZnAl layered double metal hydroxide colloidal solution;

[0030] Adding a polymer solution to the colloidal solution and mixing the polymer and the exfoliated ZnAl layered double hydroxide through electrostatic interaction or grafting to obtain a phosphorus adsorption composite material;

[0031] The high molecule is one or more of sulfonic acid polymer, iodine substituent polymer, chlorine-benzyl polymer and cellulose derivative.

[0032] According to the present invention, the polymers include natural organic polymers, such as cellulose derivatives; and synthetic organic polymers, such as sulfonic acid-based polymers, iodine-substituted polymers, and chloro-benzyl polymers. According to the present invention, the ZnAl layered double metal hydroxide is NO 3 - typ...

Embodiment 1

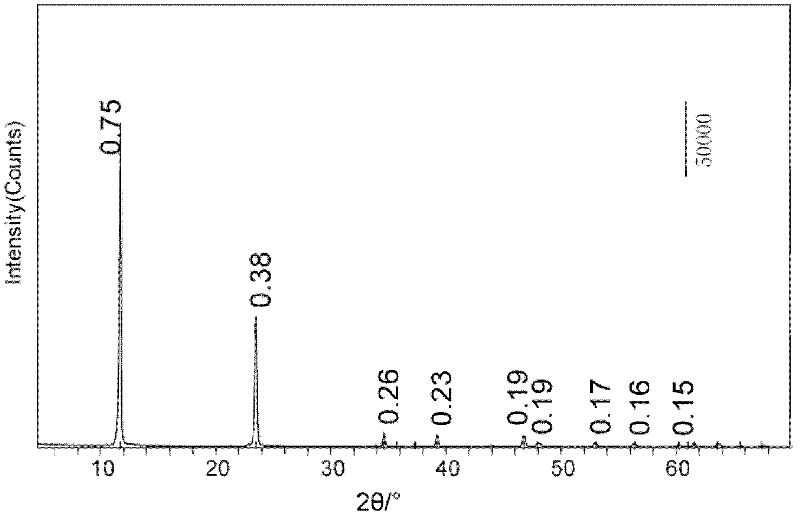

[0041] Example 1 Preparation of CO 3 2- Type ZnAl-LDH

[0042] AlCl 3 ·6H 2 O, urea and ZnCl 2 Mix with water to configure the mixed solution, the mixed solution contains 10mM Zn 2+ , 5mM Al 3+ , 35 mM urea, the mixture was heated to reflux at 100° C. and kept stirring for 24 hours. Then the precipitate was filtered, washed with deionized water and absolute ethanol, and dried under vacuum at 40 °C to obtain CO 3 2- Type ZnAl-LDH, XRD test results are as follows figure 1 shown.

Embodiment 2

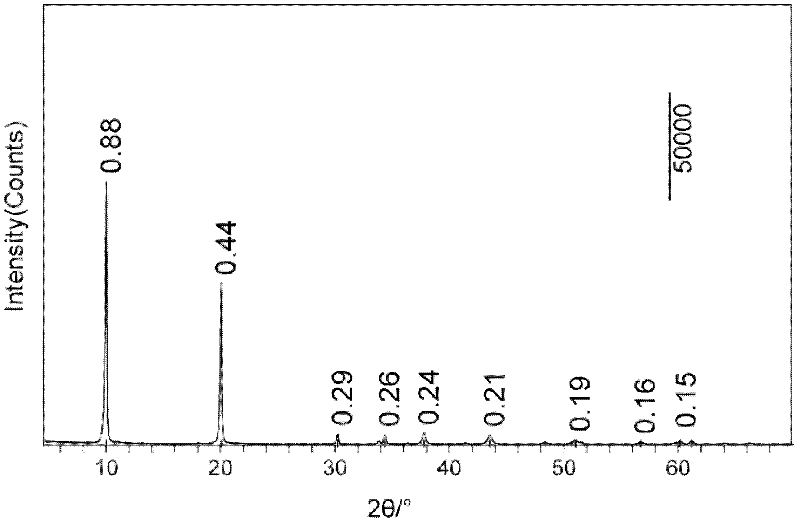

[0043] Example 2 Preparation of NO 3 - Type ZnAl-LDH

[0044] Take 1 liter of NaNO containing 2mol / L 3 and 9mmol / L HNO 3 solution into the container, take 1g of the CO 3 2- Type ZnAl-LDH is put into the container and mixes with described solution, fills N in the container 2 5 minutes and seal the container. After ultrasonic treatment for 30 minutes and stirring for 24 hours, the precipitate was filtered, washed with degassed water and absolute ethanol for 5 times, and vacuum-dried at 40°C to obtain NO 3 - Type ZnAl-LDH, XRD patterns such as figure 2 shown. from figure 2 As can be seen in the CO 3 2- Type ZnAl-LDH interlayer spacing increased from 0.75nm to 0.88nm, indicating that the interlayer carbonate ions have been completely exchanged for nitrate ions.

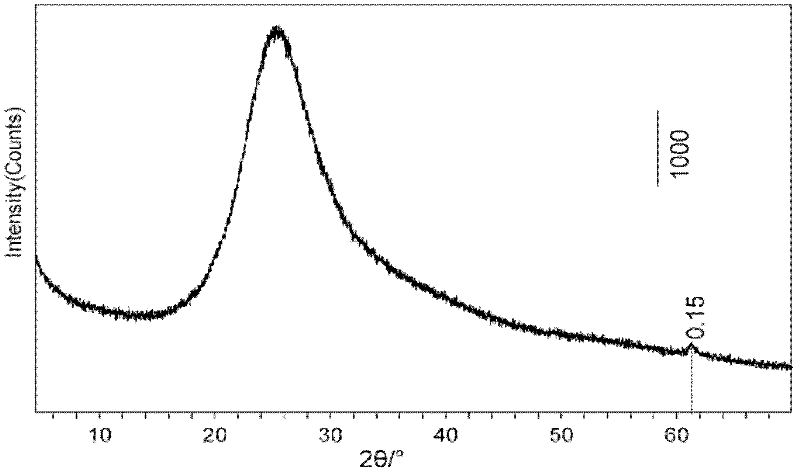

[0045] Example 3 Stripping

[0046] Take 0.1g NO 3 - Type ZnAl-LDH was added to 100mL formamide, sealed, and shaken for 24 hours to obtain a colloidal solution of ZnAl-LDH nanosheets, and the XRD pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com