Preparation method of functionalized polyacid-type sulfonic ionic liquid

An ionic liquid and multi-acid technology, applied in chemical instruments and methods, organic chemistry, refined hydrocarbon oil, etc., can solve problems such as low acidity and gap in desulfurization performance, and achieve high acid value, simple preparation method, and sufficient contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Synthesis of PSMIM (N-methylimidazolium propanesulfonate)

[0034] Synthesis of ionic liquid PSMIM with N-methylimidazole and 1,3-propane sultone: Add equimolar N-methylimidazole and 1,3-propane sultone into a three-necked flask, and then add 40ml of toluene as a solvent , stirred at 50°C for 24 hours under nitrogen protection, filtered to obtain a white solid precipitate, washed with ethyl acetate, 40°C rotary evaporation, and vacuum dried to obtain a white solid PSMIM.

[0035] The synthetic method of N-methylimidazole and sulfuric acid reaction synthesis N-methylimidazole and sulfate is the same as above.

[0036] The synthetic method of BSMIM (N-methylimidazolidine sulfonate) and its sulfate is the same as above.

[0037] The synthetic method of hexamethylenetetramine, hexamethylenediamine or bipyridyl sulfate, propane (butane) sulfonate is the same as above.

Embodiment 2

[0039] Synthesis of PSMIM polyacid ionic liquid (with [PSMIM]H 6 P 2 Mo 17 V 1 o 62 example)

[0040] PSMIM and H 7 P 2 Mo 17 V 1 o 62 Equimolar at room temperature, stirred for 24h, vacuum-dried to obtain orange-red viscous liquid which is [PSMIM]H 6 P 2 Mo 17 V 1 o 62 .

[0041] The same method can be used to synthesize various functional multi-acid sulfonic acid-based ionic liquid catalytic systems.

Embodiment 3

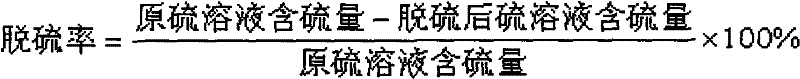

[0043] The synthesized [PSMIM]H 6 P 2 Mo 17 V 1 o 62 Put the ionic liquid and the simulated sulfur solution into a test tube at a mass ratio of 1:5, stir with a high-speed shear for 10 minutes at 40°C, cool and let stand, separate the two phases, remove the upper oil phase, measure the sulfur content and calculate desulfurization rate. The desulfurization rate is 21.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com