Culture medium and culture method for promoting fast propagation of microalgae

A culture method and culture medium technology, which are applied in the field of culture medium for promoting the rapid proliferation of microalgae, can solve the problems of slow accumulation of microalgae biomass, achieve industrial application, low cost, improve the efficiency of microalgae autotrophic metabolism and The solid effect of CO2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

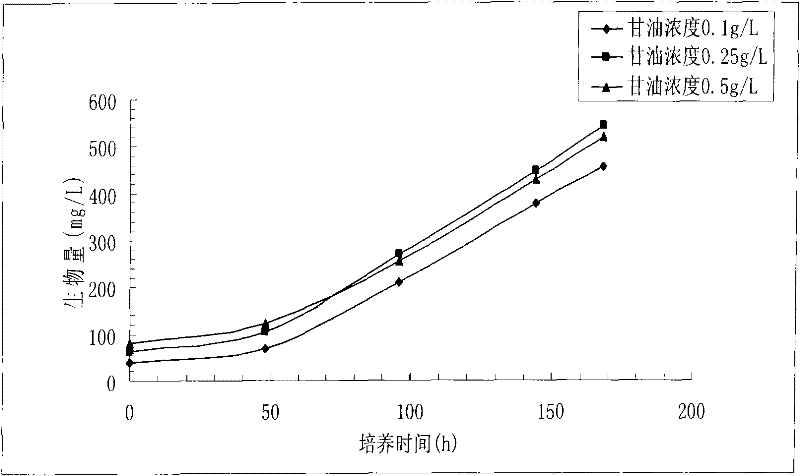

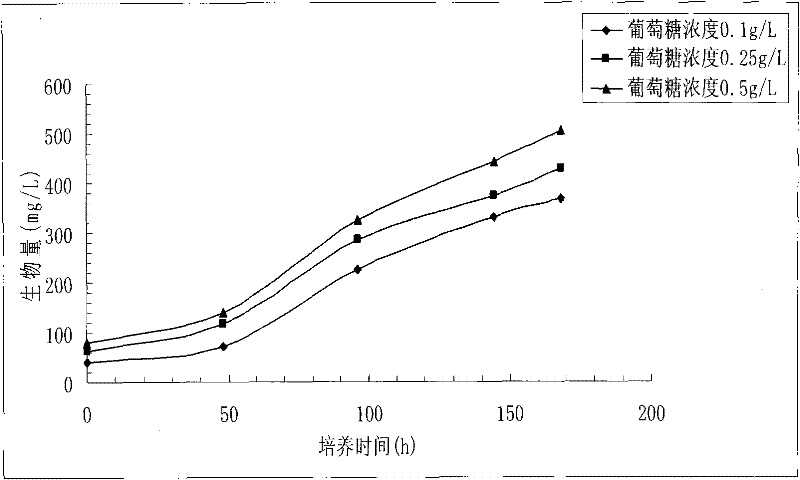

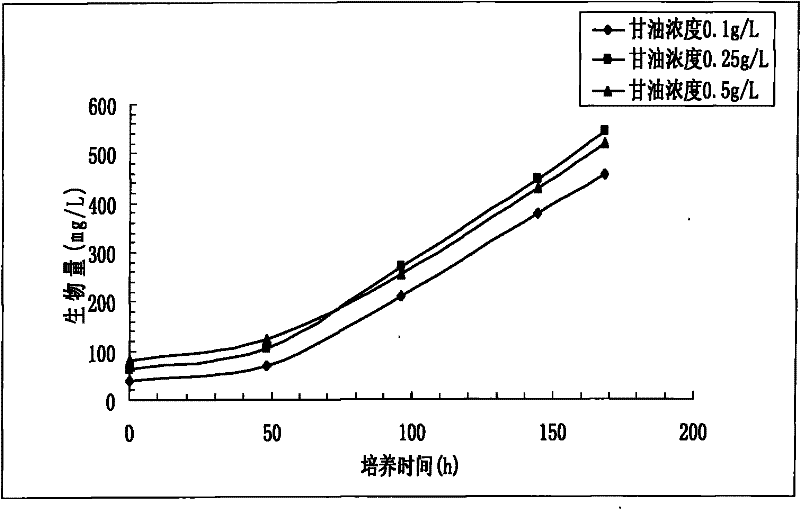

Embodiment 1

[0023](1) Glycerol is added in the conventional medium, so that the glycerol concentration in the medium is 0.1g / L, and the specific composition of the conventional medium is 0.075g / L K 2 HPO 4 ·3H 2 O, 0.175g / L KH 2 PO 4 , 0.075g / LMgSO 4 ·7H 2 O, 0.025g / L CaCl 2 2H 2 O, 0.025g / L NaCl, 0.005g / L FeCl 3 ·6H 2 O, 0.25g / LNaNO 3 .

[0024] (2) Take 10 mL of a kind of chlorella vulgaris preserved in liquid, the concentration is 800 mg / L, add 190 mL of newly prepared culture medium containing glycerin according to the volume ratio of 1:19, the concentration of microalgae thalline in the culture liquid is 40mg / L level. Seal the mouth of the triangular bottle with a breathable bacteria filter film to facilitate the air circulation of the culture environment.

[0025] (3) Select an oscillating shaker for cultivation, and set the oscillating speed at 140 rpm. The lighting system of the shaker is used to provide a continuous light condition for the culture system, and the lig...

Embodiment 2

[0027] (1) Glycerol is added in the conventional medium, so that the glycerol concentration in the medium is 0.25g / L, and the specific composition of the conventional medium is 0.075g / L K 2 HPO 4 ·3H 2 O, 0.175g / L KH 2 PO 4 , 0.075g / LMgSO 4 ·7H 2 O, 0.025g / L CaCl 2 2H 2 O, 0.025g / L NaCl, 0.005g / L FeCl 3 ·6H 2 O, 0.25g / LNaNO 3 .

[0028] (2) Take 10mL of a kind of chlorella vulgaris preserved in liquid, the concentration is about 1200mg / L, and add 190mL of newly prepared medium containing glycerin according to the volume ratio of 1:19. About 60mg / L level. Seal the mouth of the triangular bottle with a breathable bacteria filter film to facilitate the air circulation of the culture environment.

[0029] (3) Select an oscillating shaker for cultivation, and set the oscillating speed at 120 rpm. The lighting system of the shaker is used to provide a continuous light condition for the culture system, and the light intensity is 3000lux. The temperature of the entire cu...

Embodiment 3

[0031] (1) Glycerol is added in the conventional medium, so that the glycerol concentration in the medium is 0.5g / L, and the specific composition of the conventional medium is 0.075g / L K 2 HPO 4 ·3H 2 O, 0.175g / L KH 2 PO 4 , 0.075g / LMgSO 4 ·7H 2 O, 0.025g / L CaCl 2 2H 2 O, 0.025g / L NaCl, 0.005g / L FeCl 3 ·6H 2 O, 0.25g / LNaNO 3 .

[0032] (2) Take 10mL of a kind of chlorella vulgaris preserved in liquid, the concentration is about 1600mg / L, and add 190mL of newly prepared medium containing glycerin according to the volume ratio of 1:19. About 80mg / L level. Seal the mouth of the triangular bottle with a breathable bacteria filter film to facilitate the air circulation of the culture environment.

[0033] (3) Select an oscillating shaker for cultivation, and set the oscillating speed at 160 rpm. The lighting system of the shaker is used to provide a continuous light condition for the culture system, and the light intensity is 4000lux. The temperature of the entire cul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com