Preparation method for graphene

A technology of graphene and graphite, which is applied in the field of graphene solution phase preparation, can solve problems such as difficulty in obtaining high-quality and high-purity products, difficulty in large-scale preparation, multiple defects and impurities in graphene, and easy large-scale production , high yield, and less structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the first step, the above four raw materials were uniformly mixed at 30° C. and mechanically stirred for 1.5 hours according to the mass ratio of graphite: potassium permanganate: acetic anhydride: concentrated nitric acid of 1:0.4:1.7:0.5. Add water to dilute, and add 30wt.% hydrogen peroxide until no bubbles are produced. The product was washed with water until neutral and dried.

[0026] In the second step, the product in the first step was left to stand in air at 900° C. for 30 seconds, and then cooled to room temperature.

[0027] In the third step, the product in the second step was placed in air at 500° C. for 2 hours.

[0028] In the fourth step, the product obtained in the third step is dispersed in N-methylpyrrolidone solvent according to 1% by mass, and ultrasonically treated for 15 minutes to obtain a graphene suspension. After centrifugation or filtration and drying, the graphene powder material can be obtained.

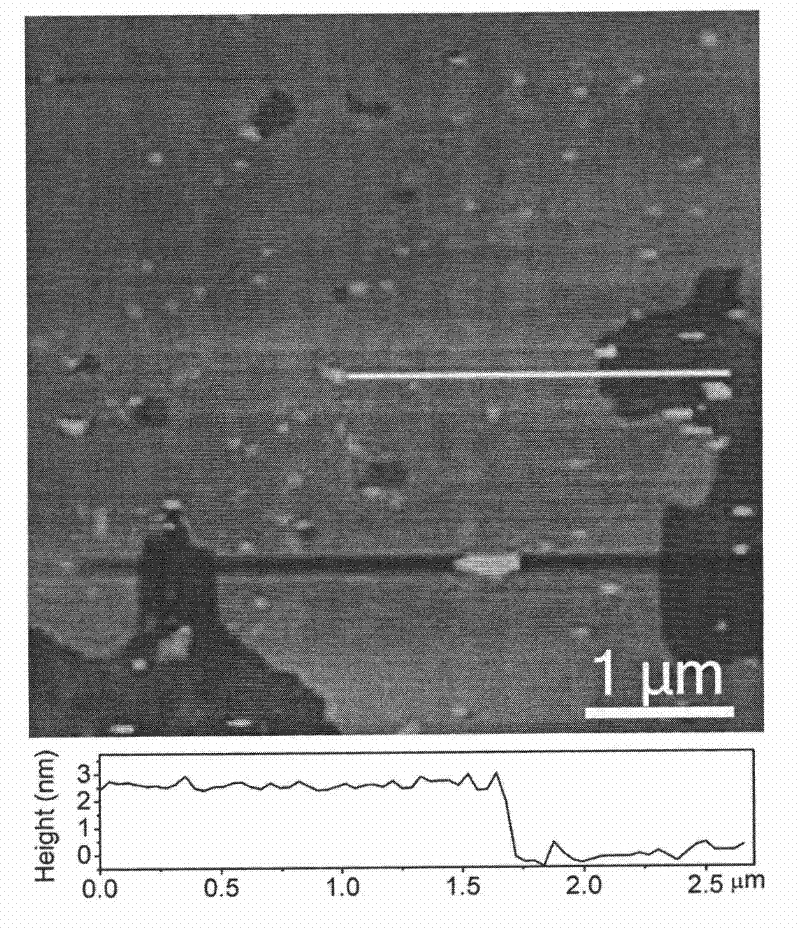

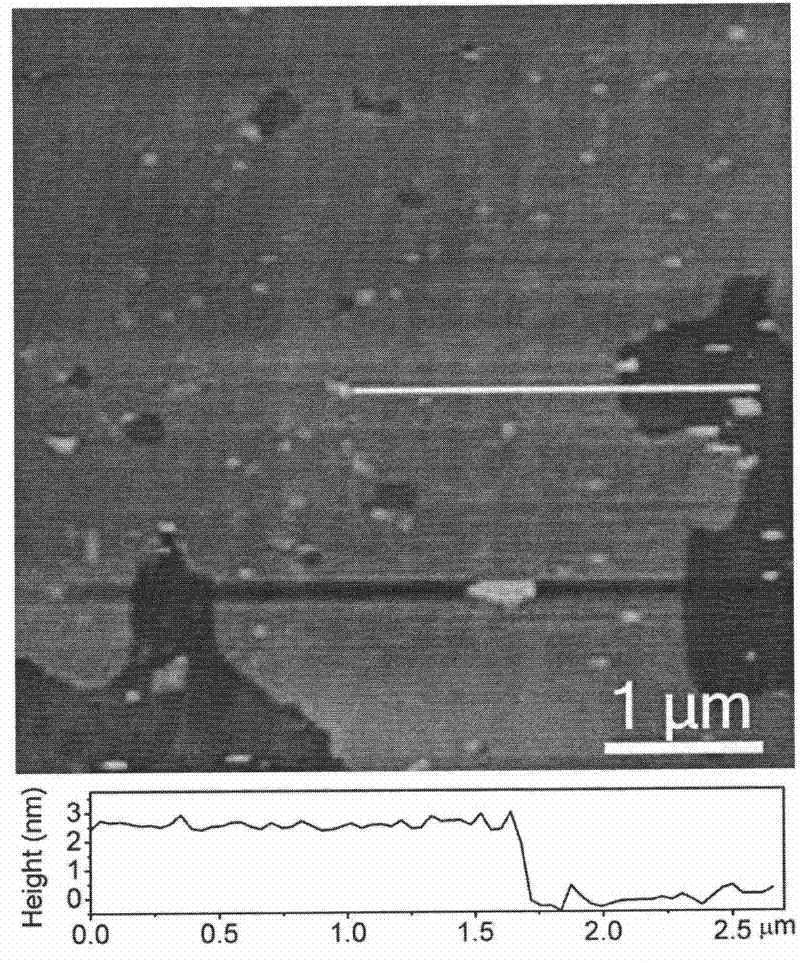

[0029] Such as figure 1 As shown, th...

Embodiment 2

[0031] In the first step, the above-mentioned three raw materials were uniformly mixed at 40° C. and mechanically stirred for 1.5 hours according to the mass ratio of graphite:concentrated sulfuric acid:hydrogen peroxide of 1:5:0.2. The product was washed with water until neutral and dried.

[0032] Subsequent steps are the same as in Example 1.

Embodiment 3

[0034] In the first step, the above four raw materials were uniformly mixed at 30° C. and mechanically stirred for 1.5 hours according to the mass ratio of graphite:concentrated sulfuric acid:concentrated nitric acid of 1:5:0.2. The product was washed with water until neutral and dried.

[0035] Subsequent steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com