Cardan universal joint, and manufacturing method for shaft sleeve for cardan universal joint

A cross shaft universal joint and manufacturing method technology, which is applied to shafts and bearings, couplings, bearing components, etc., can solve the problems of difficult assembly of cross shaft universal joints, low material utilization, inconvenient daily maintenance, etc. Machining efficiency, high material utilization, reducing the effect of machining processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

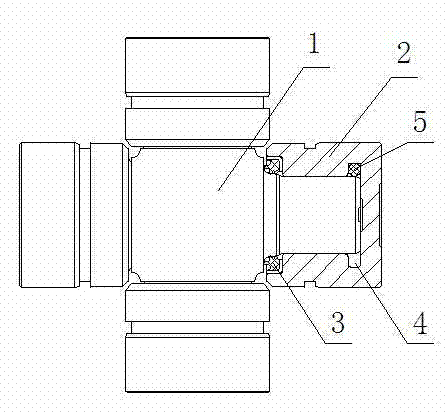

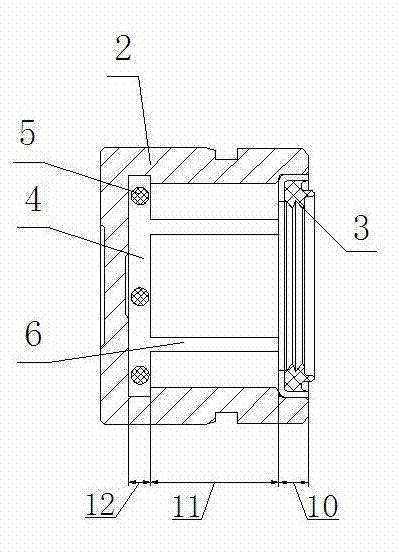

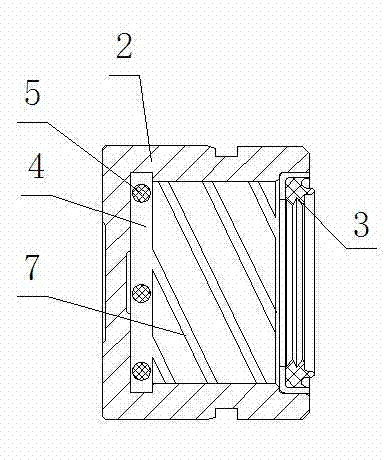

[0033] Example 1, such as figure 1 , figure 2 , image 3 The illustrated cross-shaft universal joint includes a cross shaft 1. The four ends of the cross shaft 1 are respectively sleeved with sleeves 2. The material of the sleeves 2 is powder metallurgy material, specifically powder Metallurgical anti-friction materials. Powder metallurgy anti-friction material is to add anti-friction agent such as graphite or solid lubricant to powder metallurgy powder formula to reduce the friction coefficient between the surface of powder metallurgy anti-friction material. The powder metallurgy antifriction material has a porosity of 10% to 18% by volume, and the powder metallurgy antifriction material has lubricating oil in the pores. An oil seal 3 is provided between the inner surface of the sleeve 2 and the end of the cross shaft 1. And the inner surface of the shaft sleeve 2 is in the axial direction, and three functional sections are arranged inward from the open end. The first functi...

Embodiment 2

[0035] Example 2, such as Figure 4 As shown, the sleeve 2 in the above-mentioned cross-shaft universal joint can also be configured such that the powder metallurgy material of the sleeve 2 has a porosity of 55% by volume, and the pores of the powder metallurgy material also have open-cell foamed plastics. , The inner side of the shaft sleeve is also provided with a layer of open-cell foamed plastic 8, the pores of the shaft sleeve and the open-celled foamed plastic 8 on the inner side of the shaft sleeve are connected as a whole, and the pores of the open-cell foamed plastic 8 have lubricating oil. A layer of open-cell foamed plastic 8 arranged on the inner side of the sleeve 2 is provided with three straight oil grooves or spiral oil grooves, and a number of mutually independent circular, rectangular or diamond grooves 9. The outer surface of the sleeve 2 is provided with There is a completely dense copper-based powder layer.

[0036] The shaft sleeve in this example 2 is bas...

Embodiment 3

[0037] Embodiment 3, a method for manufacturing a shaft sleeve of a cross-shaft universal joint, the shaft sleeve is made of powder metallurgy material, and the manufacturing method of the shaft sleeve at least includes the following steps:

[0038] A: Preparation of raw material powder formula, using mechanical or physical chemical methods to prepare powder, such as atomization, reduction, electrolysis, etc. The composition of powder raw materials includes Fe, Cu, C and plasticizers, and the Fe content is 97.5% , Cu content is 1.6%, C content is 0.6%;

[0039] B: The block is formed, and the blank is made by film pressing;

[0040] C: Block sintering. Place the molded block in a high temperature furnace or vacuum furnace with a protective atmosphere for sintering. The sintering temperature is between 1150°C and the sintering time is 5 hours;

[0041] D: Finishing, finishing the inner diameter, outer diameter and bottom surface of the sleeve through the finishing mold;

[0042] E: Mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com