Dispersant for pigment and use thereof

A technology of dispersant and dispersion liquid, applied in the field of dispersant for pigments and various inorganic particles, can solve the problems such as the lack of any instructions, the difficulty of dispersion and stabilization of the dispersant, the increase of the viscosity of the dispersion liquid, etc., and achieve long-term maintenance of low Excellent viscosity, stability over time, and excellent handling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

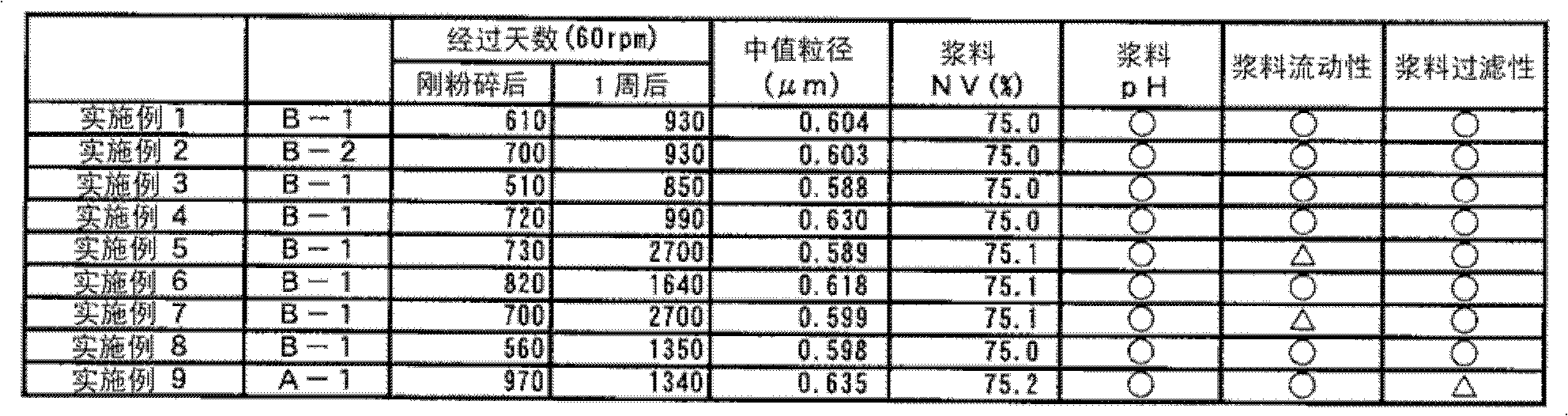

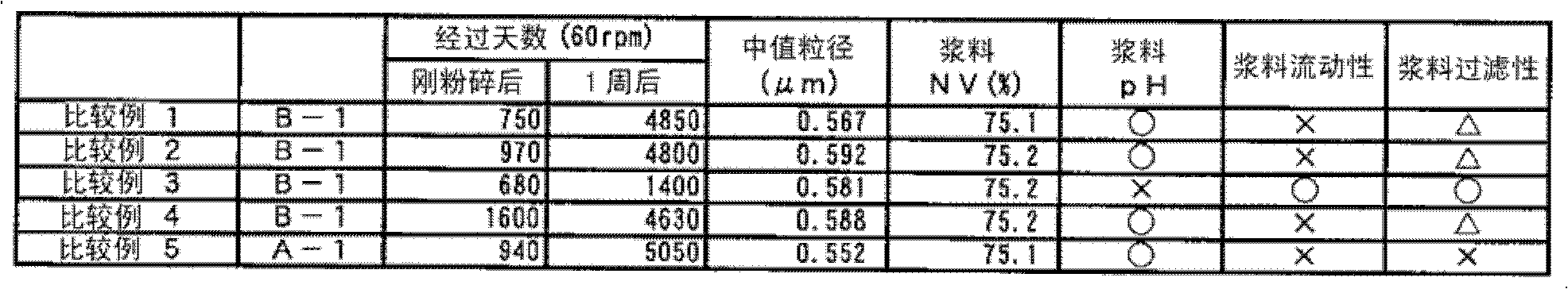

[0098] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to the following Example.

[0099] In the following examples, "%" and "part" represent "mass%" and "mass part", respectively.

[0100] In addition, in the following example, the measurement of the weight average molecular weight (Mw) and the number average molecular weight (Mn) of a (meth)acrylic-type (co)polymer, and the measurement or evaluation of the dispersion characteristic with respect to calcium carbonate were performed as follows.

[0101] [1] Weight average molecular weight (Mw) and number average molecular weight (Mn) of (meth)acrylic copolymer

[0102] The weight-average molecular weight (Mw) and the number-average molecular weight (Mn) of the (meth)acrylic (co)polymer were measured by the gel permeation chromatography (GPC) method of the following water system, the gel permeation chromatography of the water system The method is as follows: 100 μL of t...

manufacture example 1

[0124] ○Production example 1 [production of (meth)acrylic copolymer (B-1)]

[0125] (1) 114.8 g of isopropanol and 138.0 g of deionized water were filled into a four-necked flask, and the inner temperature was raised to 78°C while rotating and stirring the contents of the flask at 200 rpm. After the internal temperature became constant, 0.87 g of ammonium persulfate and 4.05 g of deionized water were added at once, and monomers consisting of 232.2 g of acrylic acid, 37.8 g of butyl acrylate, and 44.6 g of deionized water were continuously supplied for 6 hours after one minute. An aqueous solution (314.6 g in total) and a polymerization initiator aqueous solution (64.3 g in total) composed of 7.83 g of ammonium persulfate and 56.5 g of deionized water were mixed. After the continuous supply was completed, the inner temperature was kept at 78°C, and aging was performed for 1.5 hours, and then cooled to an inner temperature of 50°C. 500 mg of the reaction solution was collected ...

manufacture example 2

[0129] ○Production example 2 [production of (meth)acrylic copolymer (B-2)]

[0130] (1) In (1) of Production Example 1 (B-1), the monomer mixed aqueous solution was changed to 220.3 g of acrylic acid, polypropylene glycol monoacrylate [addition mole number of polyoxypropylene n=3, terminal hydroxyl group ( R 3 = H)] 49.7 g and a monomer mixed aqueous solution (314.6 g in total) composed of 44.6 g of deionized water were subjected to the same polymerization operation as in (1) of Production Example 1. After the reaction was completed, 500 mg of the reaction solution was collected and analyzed by gas chromatography. As a result, unreacted acrylic acid and polypropylene glycol monoacrylate were not detected.

[0131] (2) Next, the same operation as in (2) and (3) of B-1 was carried out to prepare an aqueous solution having a solid content concentration [(meth)acrylic copolymer content] of 45% (the obtained ( The meth)acrylic copolymer is referred to as "B-2").

[0132] (3) Usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com